Hello everyone...

I recently noticed a spike in prices on parts for aquariums and the same time availability was limited....

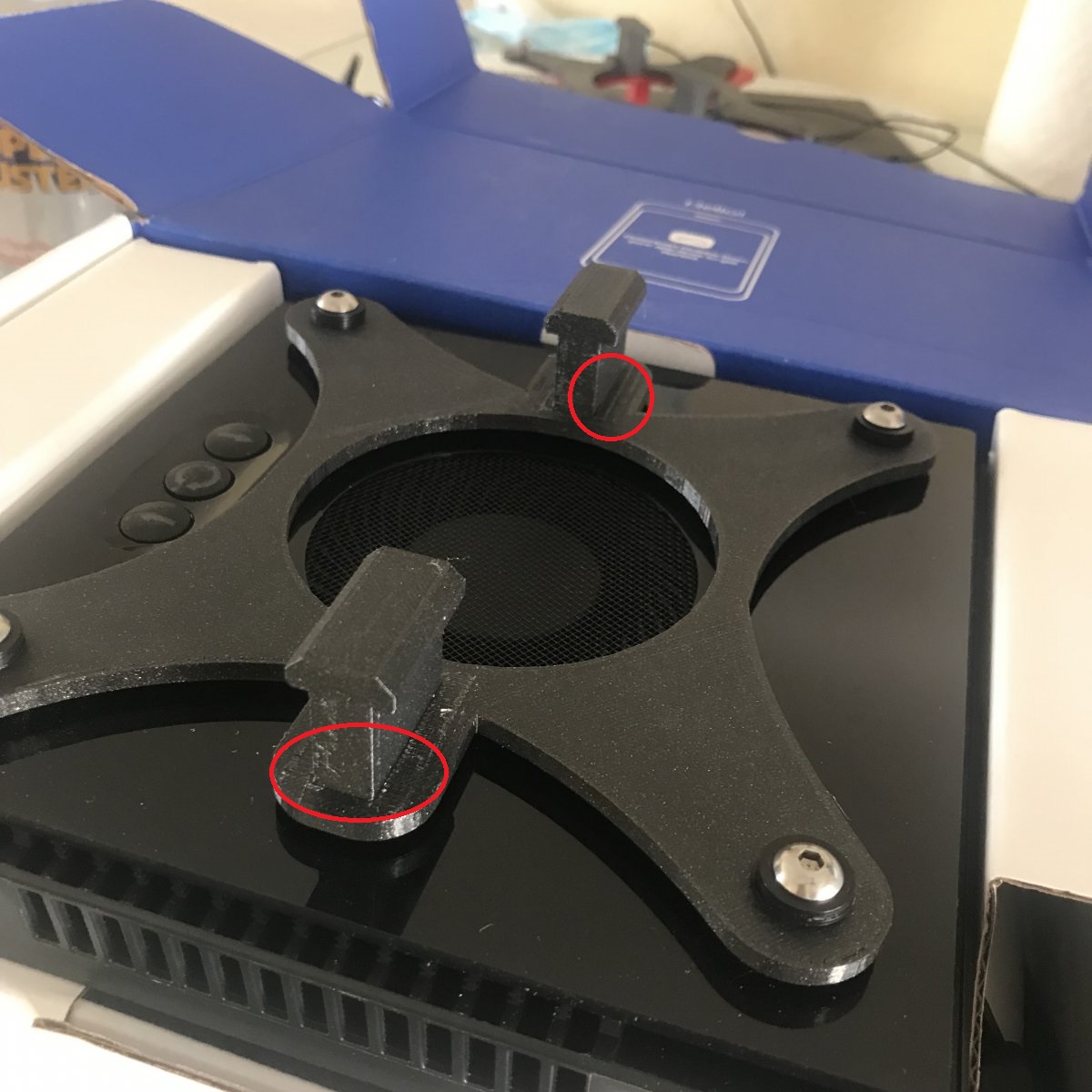

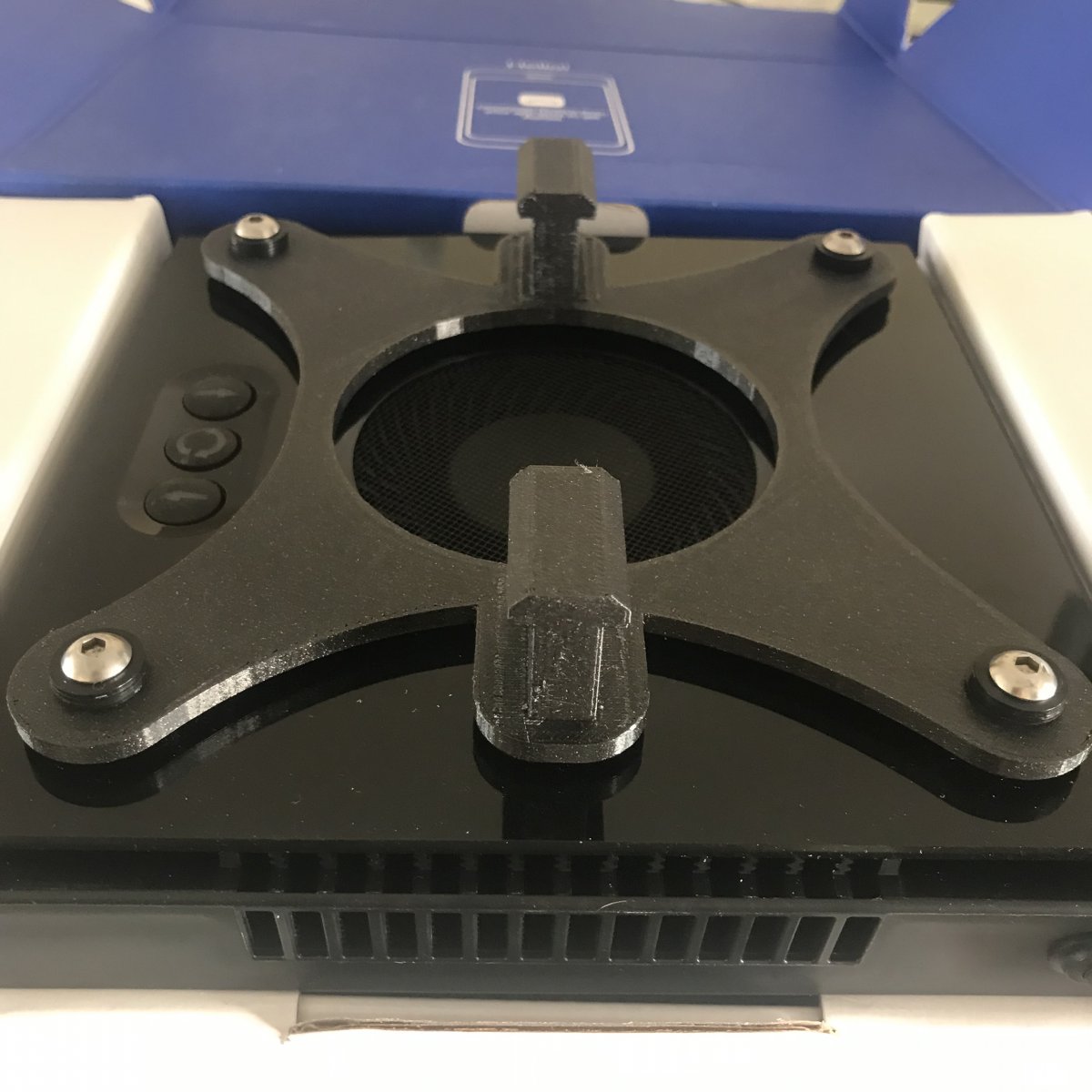

I saw this as a problem that I can solve for myself and possibly other folks out there, so I decided to purchase a 3d printer (Prusa MK3 model) and start learning and printing. the results were frustrating at first, but i was dedicated to learning the CAD and slicer software... anyways, after an entire month of practicing, trial and error, and not giving up these, this is the result of my work. If anyone else needs help with parts to print or design, just message me... This part is available for purchase if you need... made from Prusamint PETG galaxy black plastic. strong, and heat resistant. this part is $14.99 includes stainless steel M5 hardware with black nylon washer.

This part mounts on to the RMS mount only. I can design and make any type of mounting support, for any type of LED light unit.

If you need to mount other brand to the RMS rail, this can be done..

I recently noticed a spike in prices on parts for aquariums and the same time availability was limited....

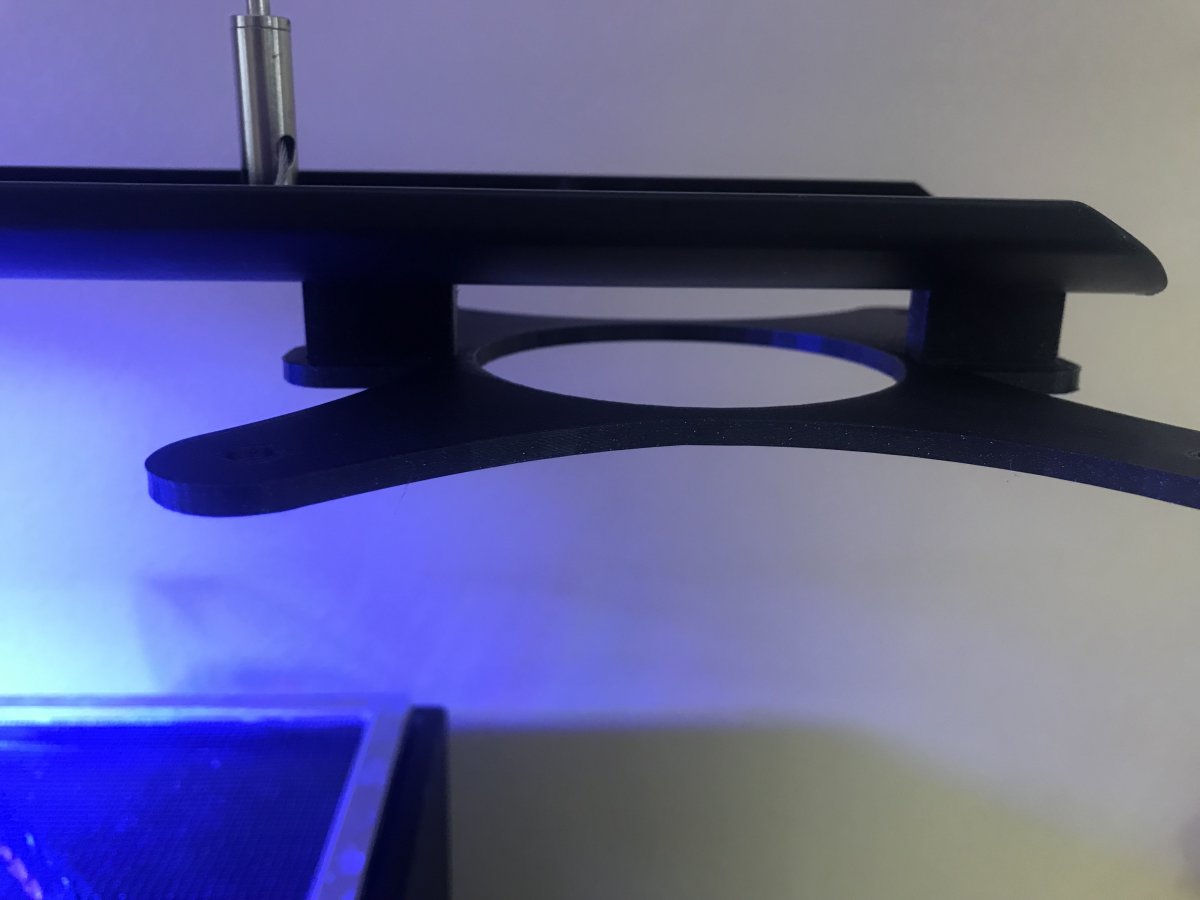

I saw this as a problem that I can solve for myself and possibly other folks out there, so I decided to purchase a 3d printer (Prusa MK3 model) and start learning and printing. the results were frustrating at first, but i was dedicated to learning the CAD and slicer software... anyways, after an entire month of practicing, trial and error, and not giving up these, this is the result of my work. If anyone else needs help with parts to print or design, just message me... This part is available for purchase if you need... made from Prusamint PETG galaxy black plastic. strong, and heat resistant. this part is $14.99 includes stainless steel M5 hardware with black nylon washer.

This part mounts on to the RMS mount only. I can design and make any type of mounting support, for any type of LED light unit.

If you need to mount other brand to the RMS rail, this can be done..