Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

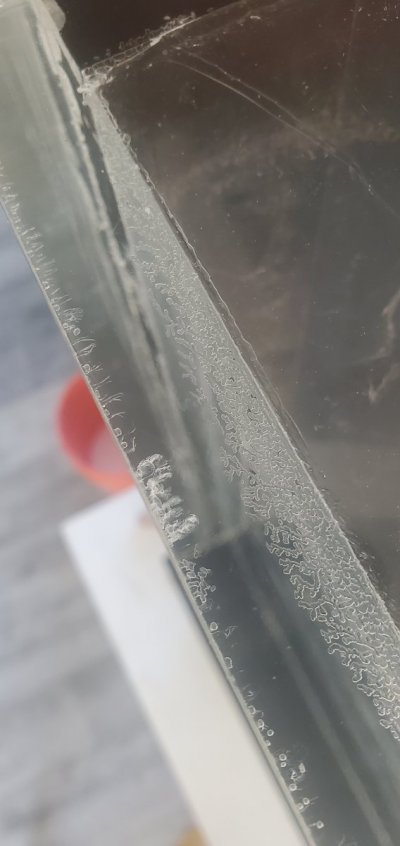

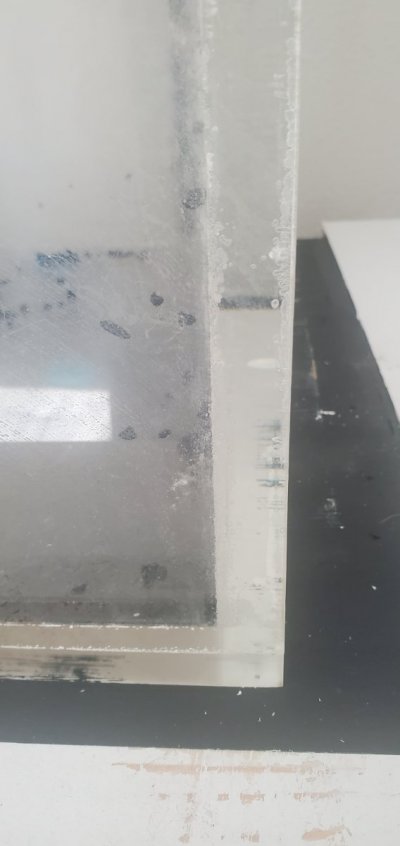

240 gallon acrylic used seams

- Build Thread

- Thread starter Fishkeepah4

- Start date

- Tagged users None

It is hard to tell if something is going on or the tank was made poorly. Air could have been sucked in during the bonding process. Its not crazing, it is between the seams. There are things you can do if you wish. Try to fill the big gaps with normal solvent. Or tilt the tank 45 degrees and pour a bead of thickened solvent (weldon 40) on the inside seam. Or weld sq rod to the inside seam. Or do nothing.

Read this for a bit more info.

Read this for a bit more info.

Is it possible to apply the solvent on the seam with the tank in place?It is hard to tell if something is going on or the tank was made poorly. Air could have been sucked in during the bonding process. Its not crazing, it is between the seams. There are things you can do if you wish. Try to fill the big gaps with normal solvent. Or tilt the tank 45 degrees and pour a bead of thickened solvent (weldon 40) on the inside seam. Or weld sq rod to the inside seam. Or do nothing.

Read this for a bit more info.

If I reinforce with square rod to the seams, would I still use weld 40? Or would weld 16 be fine.It is hard to tell if something is going on or the tank was made poorly. Air could have been sucked in during the bonding process. Its not crazing, it is between the seams. There are things you can do if you wish. Try to fill the big gaps with normal solvent. Or tilt the tank 45 degrees and pour a bead of thickened solvent (weldon 40) on the inside seam. Or weld sq rod to the inside seam. Or do nothing.

Read this for a bit more info.

Similar threads

- Replies

- 1

- Views

- 246

- Replies

- 3

- Views

- 75