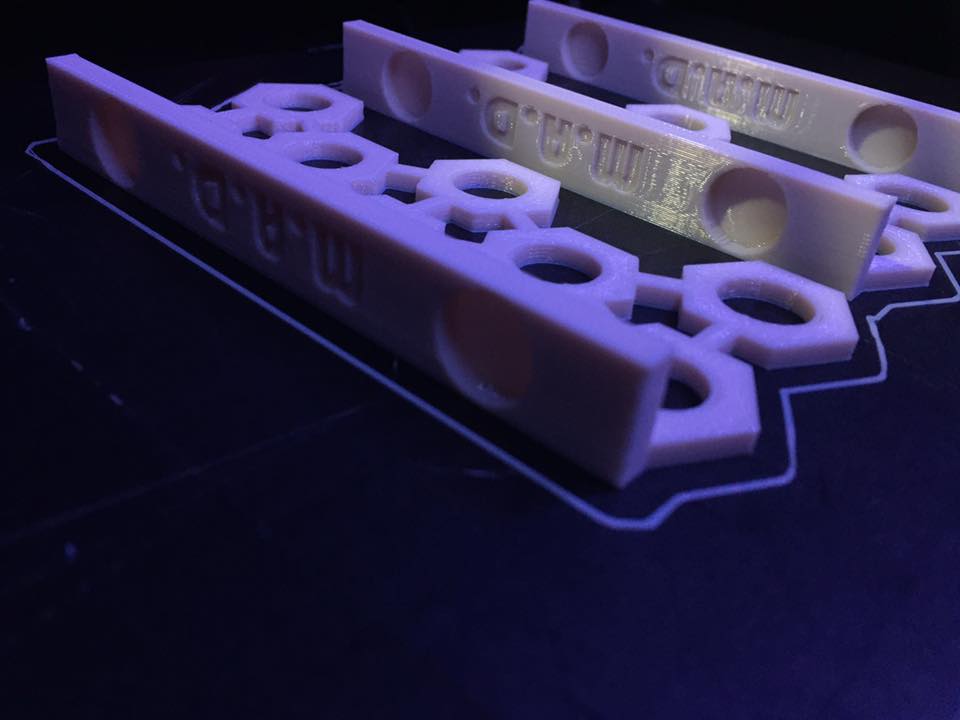

TPU to TPE? TPU was a decent printing filament. TPE... it would print, but things had to be perfect. Still don't have alot of experience with TPE and I have printed a lot of filament. I printed the InMoov Robot this year.I print with it a lot. Currently on my 5th roll of it. It's easy once you get the hang of it and your extruder is set up for it.

www.inmoov.fr