- Joined

- Feb 26, 2014

- Messages

- 467

- Reaction score

- 209

Well I just started with 3d printing I am using the tevo black widow . Besides thingiverse are they any good places to find files for our hobby

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Is the file you linked 52mm? I will have to measure my bulkheads as I plan to make some changes soon and I think you tool will work better then the one I made out of pvc pipe.You are correct on the size- I made my first one 52mm, and that fit some of my 1" bulkheads, but not others. Oddly, it was a perfect fit for a 3/4" bulkhead too. I opened it up to 53mm, and it is working fine. But it's a parametric model, so I can change one dim and re-print to get another size.

Yes, it did in between the legs. I designed the mounts in CAD and exported it out to an STL file that my brother-in-law used to load into his printer.Nice- Lots of curves, did you need to use support on the print job?

Videos that I found extremely useful:Definitely watch some videos on Fusion 360, and do the tutorials. You'll save a ton of frustration!

There are some good deal on craigs list. If you know what your want in a printer, you should be able to find one, You just have to be patient. It took me 2 months or so to find one to meat my needs. I found my Ultimaker 2+ there in perfect condition with a bunch of spools of PLA for less than half of new.I'm in the market for a printer. Anyone have for sale?

Add an axle, some bushings and some Teflon tubing and you should be able to print with filament right from the box!Drying filament

I had some issues that I thought might be due to damp filament. I measured the RH by the printer at 45-50%, at 60 F, so high enough to cause problems. After some online research, I decide I really wanted one of the PrintDry setups (http://www.printdry.com/) but they are out of stock/not shipping, and a bit expensive.

So I setup my own.

Food dryer: https://www.amazon.com/gp/product/B008H2OENC

Waterproof bins: https://www.amazon.com/gp/product/B00MWTJXHS

Desiccant: https://www.amazon.com/gp/product/B0725LNZ24

And some mesh bags I already had on hand.

Using the router table and a flush trim bit, I cut the center out of two sections of the dryer trays. It ships with six trays, so I could dry two or three spools at once, but I figured that keeping four trays intact for other uses might be a better plan.

Pour the desiccant in to the mesh bags, and put in the bins. Dry the filament and place it in the bins, and clamp down the lids.

For now, I'm not going to set it up to spool the filament out of the dryer, although that is an option if needed.

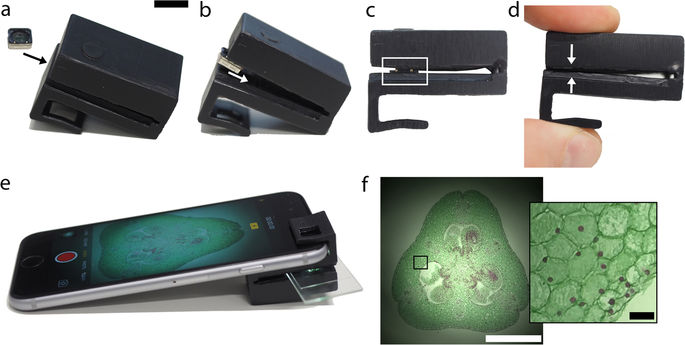

Very neat- Not sure how it gets it to focus that close though. My phone needs to be about 2" away to focus. There does not appear to be a lens in it, just a printed slide holder.

Mobile phone microscope assembly process. (a) Insert mobile phone camera lens (objective lens) into microscope clip as shown. Make sure that the side of the lens assembly that originally faced the image sensor now faces the sample (faces away from the camera). Scale bar approx. 1mm for (a–d). (b) Push objective lens further into the clip until it fits into the recess. (c) Gently push the objective lens assembly into the recess. This can be done with tweezers or by hand. The white boxed region shows the objective lens assembly sitting in the friction-fit recess. (d) Gently squeeze microscope clip so that the opposite sides of the slide holder come into contact. This pushes the objective lens assembly into its final position in the microscope clip recess. (e) Insert sample slide and attach the clip to an iPhone 6s as shown. The objective lens fits directly over the iPhone back camera. Open the iPhone camera app (or other 3rd party camera app), switch to video mode and activate the flash to view the sample in brightfield mode. In this example, the sample is Lilium ovary (Southern Biological). Exposure time: 1/4808s, ISO 25. (f) Brightfield image of Lilium ovary using “Photo” mode with flash. Scale bar is 1mm. Inset: Magnified image of boxed region. Scale bar is 50 μm.