Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone have the Bubble Magus Roller Filter?

- Thread starter Potatohead

- Start date

- Tagged users None

- Joined

- Oct 7, 2018

- Messages

- 35

- Reaction score

- 12

How big of a chamber do you need for this device?So, I just got this thing today. It seems pretty well built overall, although the weld on the little mounting L bracket for the float switch came undone from rough shipping I would presume but it was easily fixed with some glue. I will try and get it in this weekend at some point and report back with how it all works and what not.

I can make a video I have had mine running for about 6 months now.

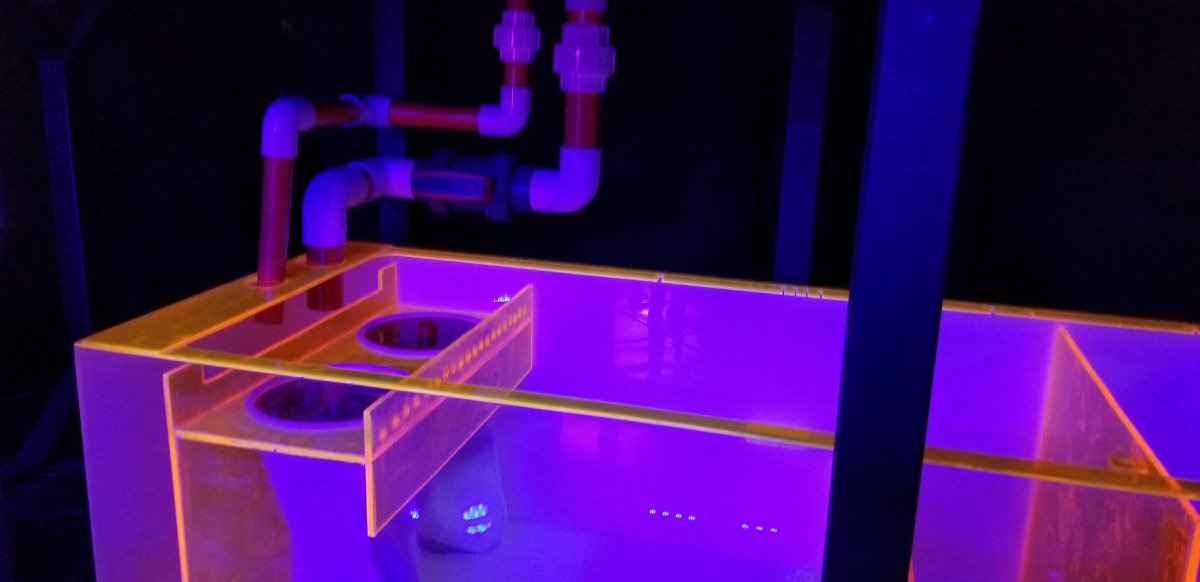

Watch "180G REEF TANK UPDATE ON SOME EQUIPTMENT" on YouTube

- Joined

- Jun 22, 2018

- Messages

- 25

- Reaction score

- 4

So, I went ahead and ordered one. The main body is 7" deep and 9" wide (roughly- this is including the brackets, so it's the amount of sump floor space you'll need). The inlet pipe comes off one side and comes out around 3.5". The motor is about 4", but higher up so it will clear shorter items like baffles or shorter reactors. It's not going to clear a skimmer. I had to reverse both sides- took about 5 minutes, and was easy enough. I read the manual after.. that's two minutes of my life I'll never get back.  The design is pretty simple and clear though, so that's not an issue at all. Outside of the manual, it looks pretty good. Disclaimer- I haven't hooked it up yet. But if you never hear from me again in this thread- it's probably working well. (Or it's a safely hazard and I was electrocuted)

The design is pretty simple and clear though, so that's not an issue at all. Outside of the manual, it looks pretty good. Disclaimer- I haven't hooked it up yet. But if you never hear from me again in this thread- it's probably working well. (Or it's a safely hazard and I was electrocuted)

Edit: I forgot to mention, it's possible to put the inlet and motor on the same side. Not sure if that was mentioned, I didn't recall seeing it though.

Edit: I forgot to mention, it's possible to put the inlet and motor on the same side. Not sure if that was mentioned, I didn't recall seeing it though.

Sorry I kind of lost track of this thread. I’ve had the unit running now since Xmas and I believe I’m on my fourth roll. The first one lasted five weeks and every one after that has been more like 8-10 weeks. All in all IMO this is a good product.

Oh that's right I did get mine for Christmas my wife bought it for me.

I have been running mine since 8-31-2019 and I still have about 80% of the roll left ..its on 120 gallon system.. water is super clear and roll is super dirty... how is lasting this long I have no clue.. running what I thing is about 500ish gph.. and sump is clean so its working

Watch "180G REEF TANK UPDATE ON SOME EQUIPTMENT" on YouTube

I bought mine in May and the lifting of the fleece is a real PITA; I've drilled / raised / lowered / tilted / reduced flow and no result. It is a dirty unit. I should mention that the first fleece that came with the unit worked great. Couldn't tell you the micron size of these replacement fleeces - that is the only unknown for why my sump is a mess when I come back from trips.

Honestly with my new sump design I will be going back to socks and no refugium. Hate my sump getting dirty.I bought mine in May and the lifting of the fleece is a real PITA; I've drilled / raised / lowered / tilted / reduced flow and no result. It is a dirty unit. I should mention that the first fleece that came with the unit worked great. Couldn't tell you the micron size of these replacement fleeces - that is the only unknown for why my sump is a mess when I come back from trips.

I bought mine in May and the lifting of the fleece is a real PITA; I've drilled / raised / lowered / tilted / reduced flow and no result. It is a dirty unit. I should mention that the first fleece that came with the unit worked great. Couldn't tell you the micron size of these replacement fleeces - that is the only unknown for why my sump is a mess when I come back from trips.

What floss are you using? I have only ever used the BM rolls and I haven't noticed an issue with it lifting off the sides of the unit. My sump isn't 100% clean but I don't know I would want it to be. If this catches 80% or more which is probably does I am happy with that. The spent roll in that video is not nearly as dirty as it should be. Mine is solid brown.

As another update I increased my flow through the sump recently by about 20% and now I am getting about 6-7 weeks per roll.

I'm using the BM branded floss - the unit is placed so that the sump level is halfway across the "sight glass" below the float switch. It looks like a differential pressure issue - are you running with the ARF1 model?What floss are you using? I have only ever used the BM rolls and I haven't noticed an issue with it lifting off the sides of the unit. My sump isn't 100% clean but I don't know I would want it to be. If this catches 80% or more which is probably does I am happy with that. The spent roll in that video is not nearly as dirty as it should be. Mine is solid brown.

I'm using the BM branded floss - the unit is placed so that the sump level is halfway across the "sight glass" below the float switch. It looks like a differential pressure issue - are you running with the ARF1 model?

Yes - I started this thread. Mine has been running just over a year.

One thing I noticed is you can switch around the side the motor sits on which also forces you to run the roll on the other side of the plastic rollers in order for it to be held taut. Just for packaging reasons in my sump I had to switch the motor to the same side as the inlet and reverse the way the floss goes over the last roller. Also on the slack side I switched the roll so it goes over the top, then on the outside of the plastic roller, then inside the plastic cage. This seems to keep it tighter as well.

My first two rolls ran like a champ without lifting and I was really happy; the last set of replacement fleeces have not behaved the same. This one is the third roll (different supplier - same problems). Perhaps I can try to change the motor side as a last chance option. Thanks for replying - I'll be away for 3 weeks and am trying to mitigate a "mess".Yes - I started this thread. Mine has been running just over a year.

One thing I noticed is you can switch around the side the motor sits on which also forces you to run the roll on the other side of the plastic rollers in order for it to be held taut. Just for packaging reasons in my sump I had to switch the motor to the same side as the inlet and reverse the way the floss goes over the last roller. Not sure if that helps or not.

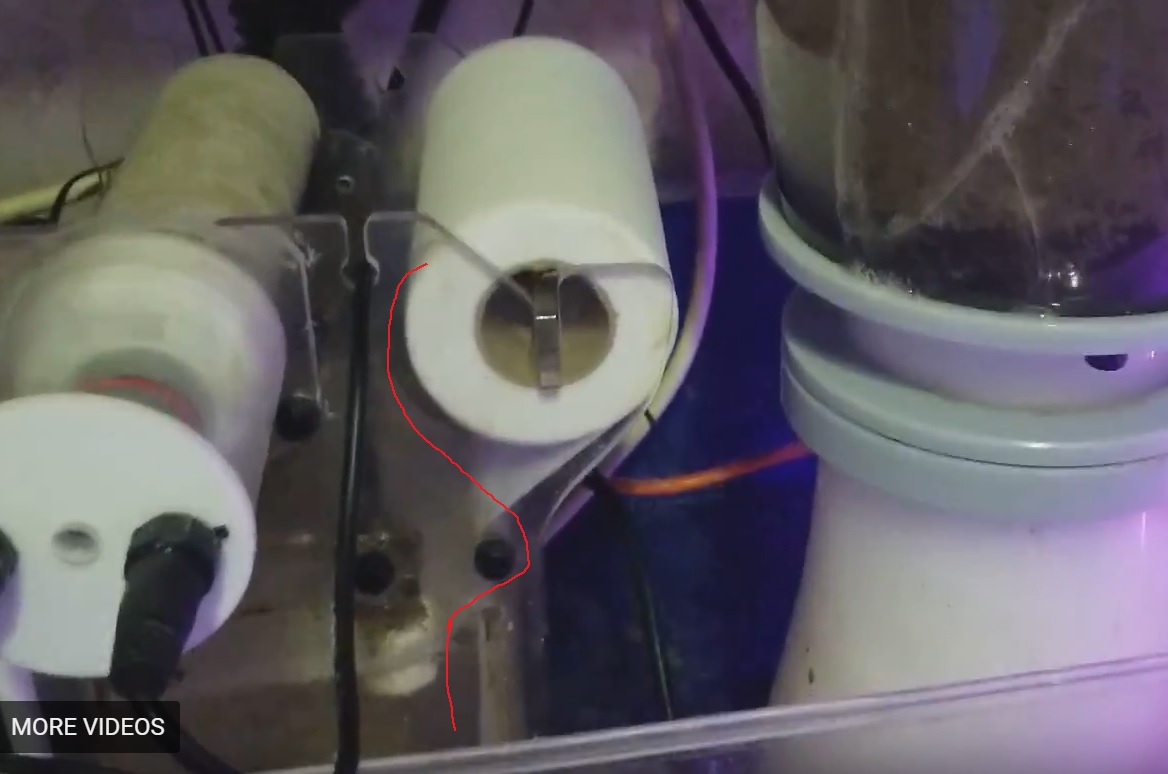

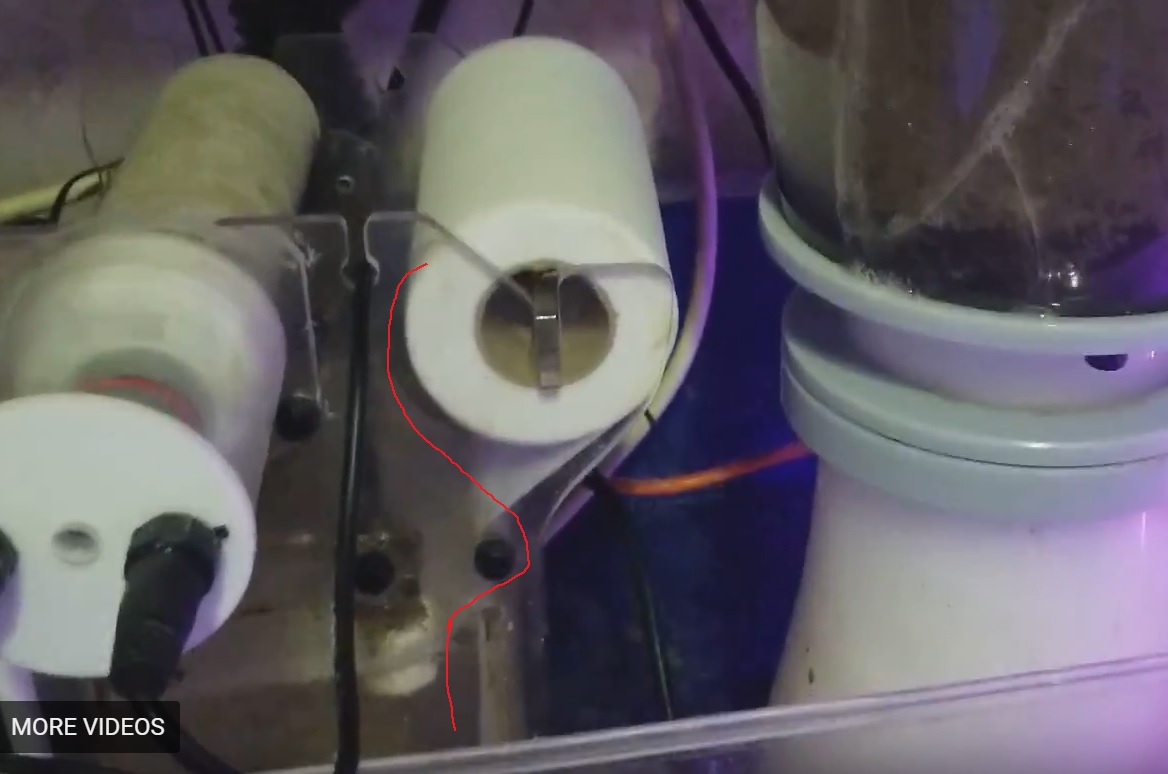

Here's a screen shot from the video as to how I oriented the slack side. I actually did this by accident because I took it all apart and forgot, but I've been running it like that for months and I prefer it

I ran mine this way to get rid of some of the slack may I will be 2 years in and I'm still on my third roll. I run about 2000+ GPH thru it this last roll is completely brown. My new sump I will be sticking with socks and no roller.

Similar threads

- Replies

- 5

- Views

- 117

- Replies

- 11

- Views

- 288

- Replies

- 2

- Views

- 312

- Price: 400

- Shipping NOT Available

- Replies

- 7

- Views

- 239