Has anyone cold forged steel or aluminum to make a diy light bracket?

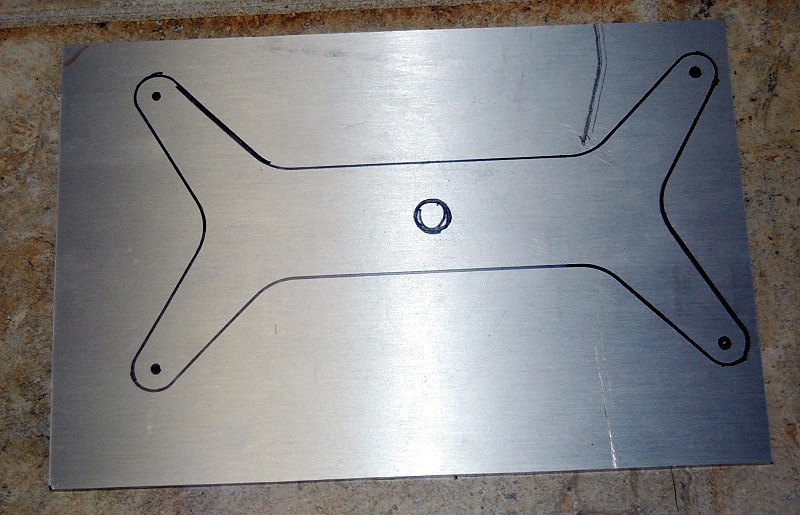

I've got access to some stainless steel (3" and 6" wide) that I was thinking about making a diy light bracket to mount an AI hydra and T5s off of. I could always buy a fixture but this material is free I would grind edges and paint before use to clean it up. Just curious if anyone had tried/completed this before and if you had any lessons or recommendations.

I would grind edges and paint before use to clean it up. Just curious if anyone had tried/completed this before and if you had any lessons or recommendations.

This would be for an IM 25 lagoon.

Thanks!

I've got access to some stainless steel (3" and 6" wide) that I was thinking about making a diy light bracket to mount an AI hydra and T5s off of. I could always buy a fixture but this material is free

This would be for an IM 25 lagoon.

Thanks!