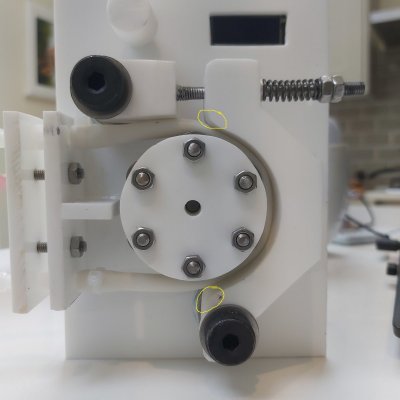

Plan is to have a good at making a Borat Pump, here is the original thread, and Borat has said it is not problem to copy... so here I go.

The only difference is I plan to use electricity ..LOL

https://www.reef2reef.com/threads/d...ings-of-glorious-nation-of-kazakistan.856269/

What Borat has built is simply unreal so I would like to make one.

Wiring is my down side, the building part I think I can do.. I have never built anything with Acrylic.

Borat has offered to help with the wiring and programming - so thanks.!

I am using Autodesk Fusion 360 to draw the part, I only have VERY limited skills.. like I mean REALLY LIMITED... skill.

This part took a long time... but I got there.

Once I have it drawn up, I will get the bits laser cut where possible.

The only difference is I plan to use electricity ..LOL

https://www.reef2reef.com/threads/d...ings-of-glorious-nation-of-kazakistan.856269/

What Borat has built is simply unreal so I would like to make one.

Wiring is my down side, the building part I think I can do.. I have never built anything with Acrylic.

Borat has offered to help with the wiring and programming - so thanks.!

I am using Autodesk Fusion 360 to draw the part, I only have VERY limited skills.. like I mean REALLY LIMITED... skill.

This part took a long time... but I got there.

Once I have it drawn up, I will get the bits laser cut where possible.