- Joined

- Apr 28, 2015

- Messages

- 586

- Reaction score

- 454

RODI water has many uses in industry including in hospitals and biofilm formation is a major problem. There are different professional ways to deal with that, but most of the options are out of reach for aquarium hobbyists. Is that something you should care about? The answer is: Maybe.

Searching for information on this issue, I found no mention on websites selling whole house filter system or RODI.

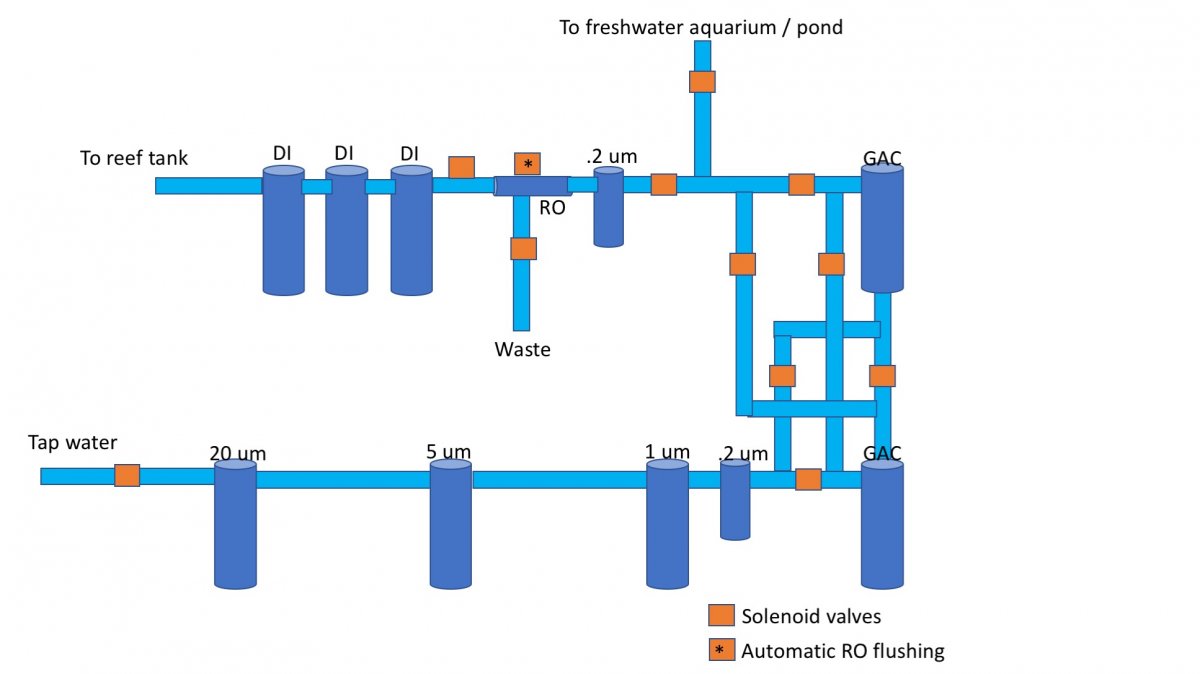

I have a somewhat large home "water treatment" system that I use for my reef tank and fresh water aquarium (and I will likely start using for my pond too). Out of that, I collect two different water fractions: 1. particle filtered and dechlorinated water, and 2. RODI water. The system consists of a series of 5 large big blue casings (for 20x4.5 cartridges) with 3 sediment and 2 GAC, followed by two RO membranes (200 gpd) and 3 large big blue canisters with DI resin.

Recently the water coming from my system started to smell like rotten eggs. Likely, the reason for that is the presence of "sulfur bacteria" biofilm that grew after the first carbon block filter. For the ones that never really thought about that, since chorine usually damage the RO membranes, it needs to be removed prior to the reverse osmosis passage. The problem is that once the chlorine is removed, there is nothing inhibiting bacterial growth. Most of the times these bacteria are not dangerous, but will colonize everything after the first carbon filter (in my case, I would likely not even notice them if it was not for the smell). You probable want to think about th at if you are using an RO system to purify your drinking water.

Anyways, there are a few things that I am planning to do to remediate that: 1. I will flush the filter housings with 10% bleach, let it soak for 6 hours and then flush it a second time with a new batch of 10% bleach (and finely I will flush the system with a prime solution). 2. I will rotate the carbon blocks so it decreases the chances of bacteria growing on either of them. 3. I will change the carbon blocks more frequently (every 5-6 months). 4. I am placing an absolute .2 um sediment filter prior to the carbon blocks, and one prior to the RO membrane to protect the membrane.

Since I am changing the configuration of the system I will also automatize the whole water treatment using solenoid valves and the Apex controller. I plan to automatize the carbon blocks rotation and the RODI production including the membrane flushing and wasting a the first fraction of RO water produced until the membrane stabilizes. I will also add a port for flushing the system with a peristaltic pump in the future.

Here is the diagram:

Searching for information on this issue, I found no mention on websites selling whole house filter system or RODI.

I have a somewhat large home "water treatment" system that I use for my reef tank and fresh water aquarium (and I will likely start using for my pond too). Out of that, I collect two different water fractions: 1. particle filtered and dechlorinated water, and 2. RODI water. The system consists of a series of 5 large big blue casings (for 20x4.5 cartridges) with 3 sediment and 2 GAC, followed by two RO membranes (200 gpd) and 3 large big blue canisters with DI resin.

Recently the water coming from my system started to smell like rotten eggs. Likely, the reason for that is the presence of "sulfur bacteria" biofilm that grew after the first carbon block filter. For the ones that never really thought about that, since chorine usually damage the RO membranes, it needs to be removed prior to the reverse osmosis passage. The problem is that once the chlorine is removed, there is nothing inhibiting bacterial growth. Most of the times these bacteria are not dangerous, but will colonize everything after the first carbon filter (in my case, I would likely not even notice them if it was not for the smell). You probable want to think about th at if you are using an RO system to purify your drinking water.

Anyways, there are a few things that I am planning to do to remediate that: 1. I will flush the filter housings with 10% bleach, let it soak for 6 hours and then flush it a second time with a new batch of 10% bleach (and finely I will flush the system with a prime solution). 2. I will rotate the carbon blocks so it decreases the chances of bacteria growing on either of them. 3. I will change the carbon blocks more frequently (every 5-6 months). 4. I am placing an absolute .2 um sediment filter prior to the carbon blocks, and one prior to the RO membrane to protect the membrane.

Since I am changing the configuration of the system I will also automatize the whole water treatment using solenoid valves and the Apex controller. I plan to automatize the carbon blocks rotation and the RODI production including the membrane flushing and wasting a the first fraction of RO water produced until the membrane stabilizes. I will also add a port for flushing the system with a peristaltic pump in the future.

Here is the diagram: