- Joined

- Apr 8, 2020

- Messages

- 247

- Reaction score

- 224

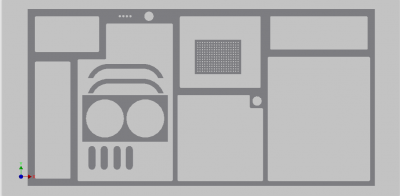

Hi Mason,Very glad you mentioned this, I looked more into this and I am reading the thickness matters, so 1/4" up will have a smaller chance of bowing, so I will be adding baffle to lid supports. I will be changing the lids from 1/8" to 1/4", it won't sit flush, but it will be an area to finish with the cutout waste portion from the lip that the lid sits on. I will be addressing all of these problems with the prototype as it happens so I can't tell you how much I appreciate the foresight. I am working with consulting from a large local reef shop manager, who tells me the dirty secret issues they deal with different brand sumps, and how to fix it

He is correct, it will most likely warp. I made some nice lids for my Bashsea sump and used 1/4" acrylic and they looked great-for about two weeks. They warped pretty badly and are now useless. I have an acrylic tank and the overflow box has an acrylic lid that is pretty thick, I'm not home to measure it at the moment but I'd guess it's 3/8" with another piece welded underneath it for I guess bracing, and it too warped within a few weeks.

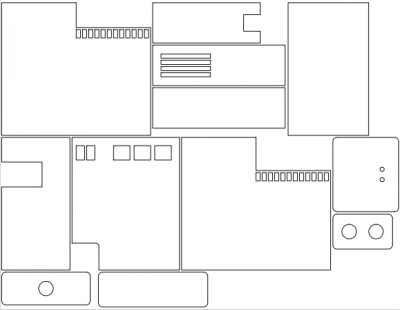

Anyway; here are a couple of photos just after I made the lids for my sump, unfortunately I do not have any pics after they warped.