Hello all,

Here’s my detailed plans with a parts list for a saltwater mixing station project I just completed. It isn’t anything novel, but I thought a shopping list along with some tips and tricks would be appreciated. Basically I built a sturdy stand out of 2x4s and plywood and painted it white. This was put into a small closet next to my fish tank. 2 plastic tanks go on top, plastic bins go underneath for storage (salt, testing kits, hoses, etc). The plumbing accomplishes the following: circulate within either tank, transfer from one tank to another, pump out from either tank through a flexible hose (water change & ato reservoir fillup). Inside the tanks, there are angled outlets to provide a mixing function as well. Obviously the rodi tank has an additional float valve accepting clean rodi.

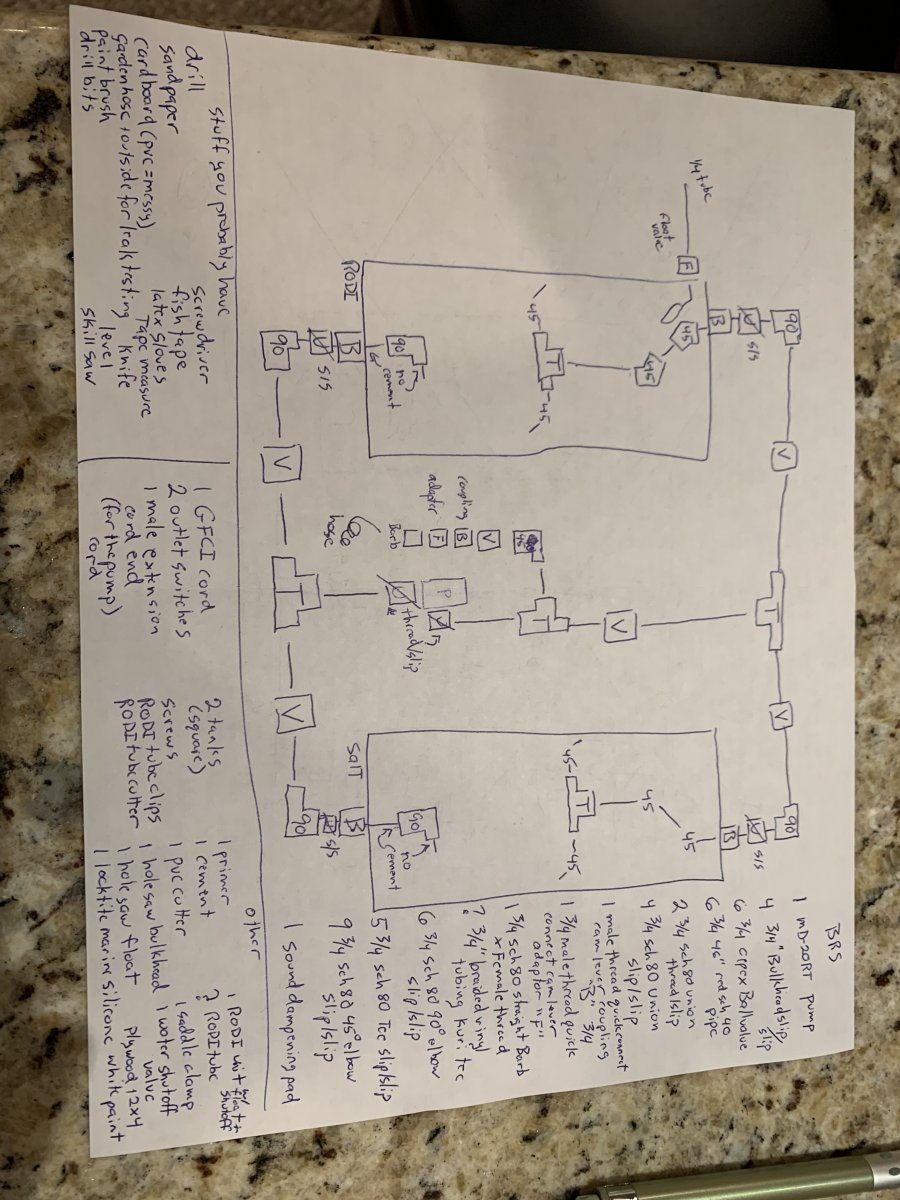

The hand written plans (I’ll type up the parts list so you don’t have to read my messy handwriting):

The final product:

The inside plumbing (missing the elbow on the inlet)

It comes apart into 2 tanks, and three major pipe sections. It’s pretty easy to break down and move (for cleaning and whatnot)

Here’s my detailed plans with a parts list for a saltwater mixing station project I just completed. It isn’t anything novel, but I thought a shopping list along with some tips and tricks would be appreciated. Basically I built a sturdy stand out of 2x4s and plywood and painted it white. This was put into a small closet next to my fish tank. 2 plastic tanks go on top, plastic bins go underneath for storage (salt, testing kits, hoses, etc). The plumbing accomplishes the following: circulate within either tank, transfer from one tank to another, pump out from either tank through a flexible hose (water change & ato reservoir fillup). Inside the tanks, there are angled outlets to provide a mixing function as well. Obviously the rodi tank has an additional float valve accepting clean rodi.

The hand written plans (I’ll type up the parts list so you don’t have to read my messy handwriting):

The final product:

The inside plumbing (missing the elbow on the inlet)

It comes apart into 2 tanks, and three major pipe sections. It’s pretty easy to break down and move (for cleaning and whatnot)