- Joined

- Jun 18, 2018

- Messages

- 56

- Reaction score

- 52

Hi All,

Figured Id share a new project I'm going to be working on.

Tired of waiting for that 55 gal drum to heat up to temperature? I always need it sooner rather than later too...

The reason it takes forever to get to temperature is because of the relatively small surface area used to dissipate the heat from the heater as shown above.

What if we used the whole plastic drum to dissipate heat?

Efficiency...

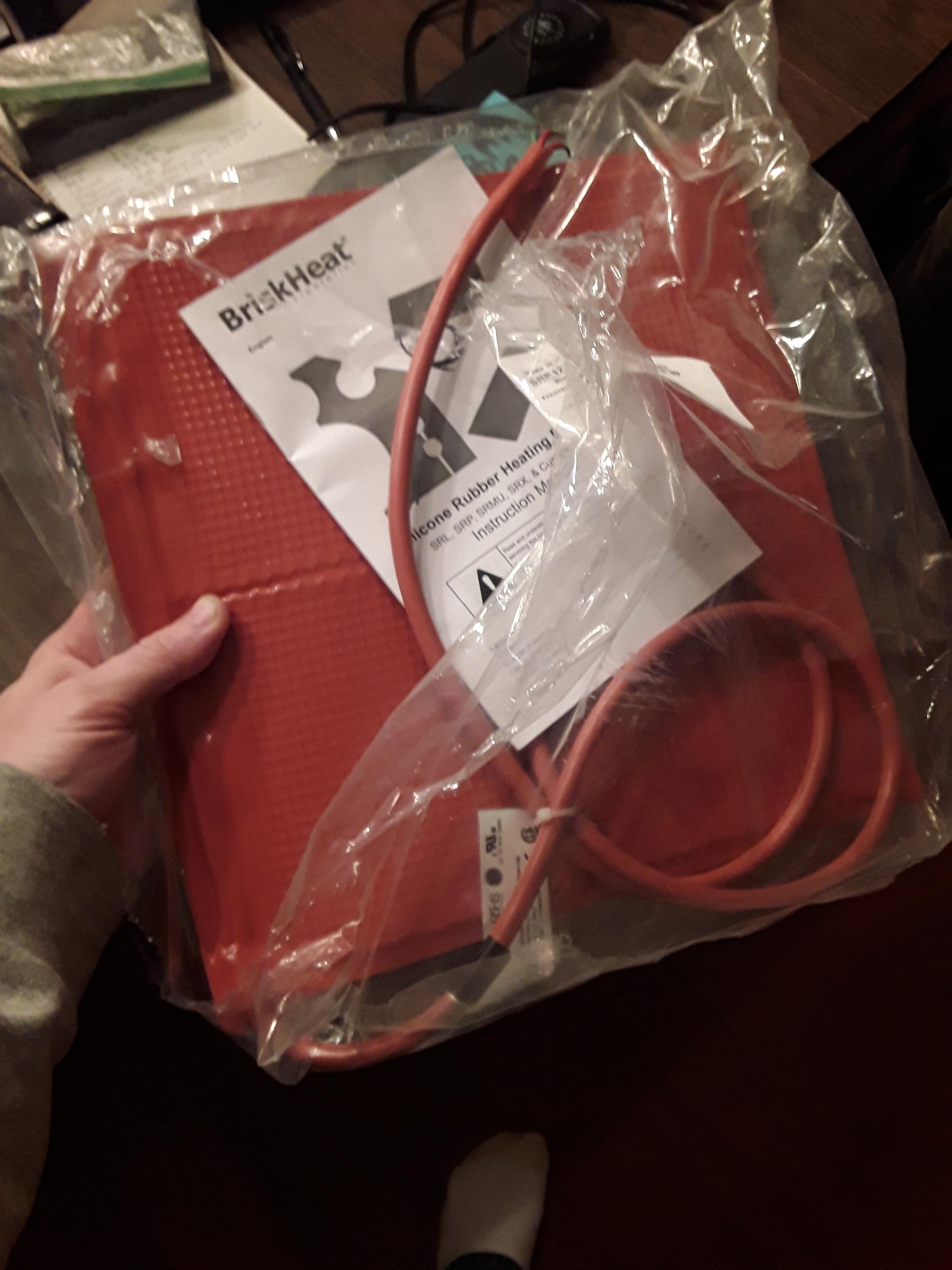

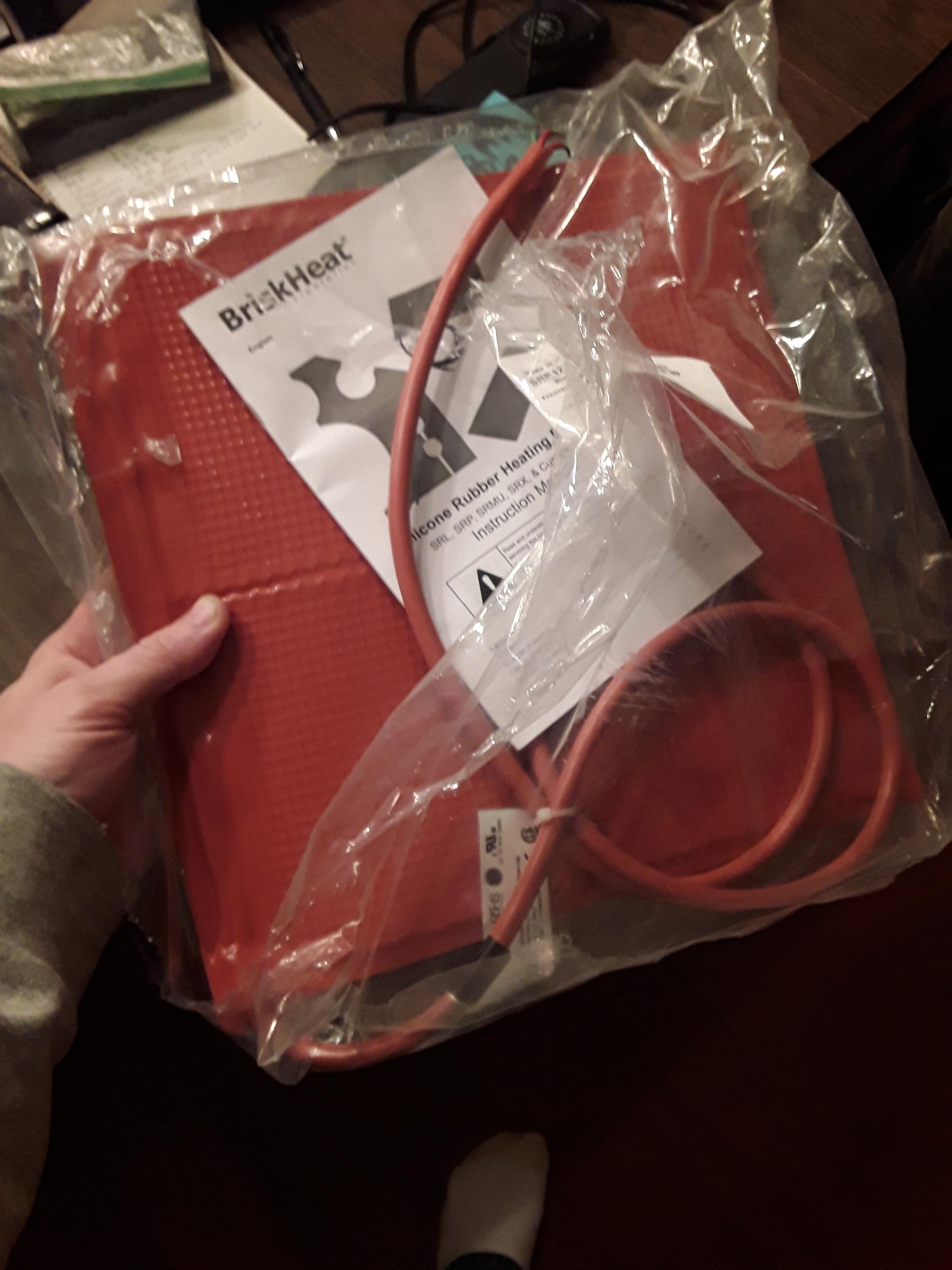

We'll use an industrial vat heating blanket, a resistive wire element sealed in a silicone type blanket, one side has a very strong adhesive backing, this unit I believe is 180W. Like so...

To control this heating element and our drum temperature well need a temperature control relay and temperature sensor...

Here we go.

Ranco SPDT relay Electronic Temperature Control with sensor this particular unit is a dual stage for heating and cooling typically used in HVAC/refridgeration a single stage would suffice.

Well wire the 120VAC cord from the blanket to the internal relay of the Ranco above, then wire a typical 120VAC power cord to the ranco unit, that way we can just plug it in and were heating.

Well probably glue the ranco to the drum and well stick the adhesive blanket on, stick the temp sensor in the drum and we have our plug and play DIY heated drum. This is how some of industry typically heats chemical drums, and should have our water at temperature in no time!

Project starts tomorrow, if anyone is interested, needs more information or any other photos let me know, otherwise I just thought Id share an idea I had.

Figured Id share a new project I'm going to be working on.

Tired of waiting for that 55 gal drum to heat up to temperature? I always need it sooner rather than later too...

The reason it takes forever to get to temperature is because of the relatively small surface area used to dissipate the heat from the heater as shown above.

What if we used the whole plastic drum to dissipate heat?

Efficiency...

We'll use an industrial vat heating blanket, a resistive wire element sealed in a silicone type blanket, one side has a very strong adhesive backing, this unit I believe is 180W. Like so...

To control this heating element and our drum temperature well need a temperature control relay and temperature sensor...

Here we go.

Ranco SPDT relay Electronic Temperature Control with sensor this particular unit is a dual stage for heating and cooling typically used in HVAC/refridgeration a single stage would suffice.

Well wire the 120VAC cord from the blanket to the internal relay of the Ranco above, then wire a typical 120VAC power cord to the ranco unit, that way we can just plug it in and were heating.

Well probably glue the ranco to the drum and well stick the adhesive blanket on, stick the temp sensor in the drum and we have our plug and play DIY heated drum. This is how some of industry typically heats chemical drums, and should have our water at temperature in no time!

Project starts tomorrow, if anyone is interested, needs more information or any other photos let me know, otherwise I just thought Id share an idea I had.