I'm one day into a reboot of my 50g SCA cube. I was originally planning to paint the stand and reuse it, but after getting the sump out I realized the MDF was severely degraded on the one side. In the trash it will go! I haven't made my own stand before, so this will be a first for me. I'd appreciate all the advice you can give!

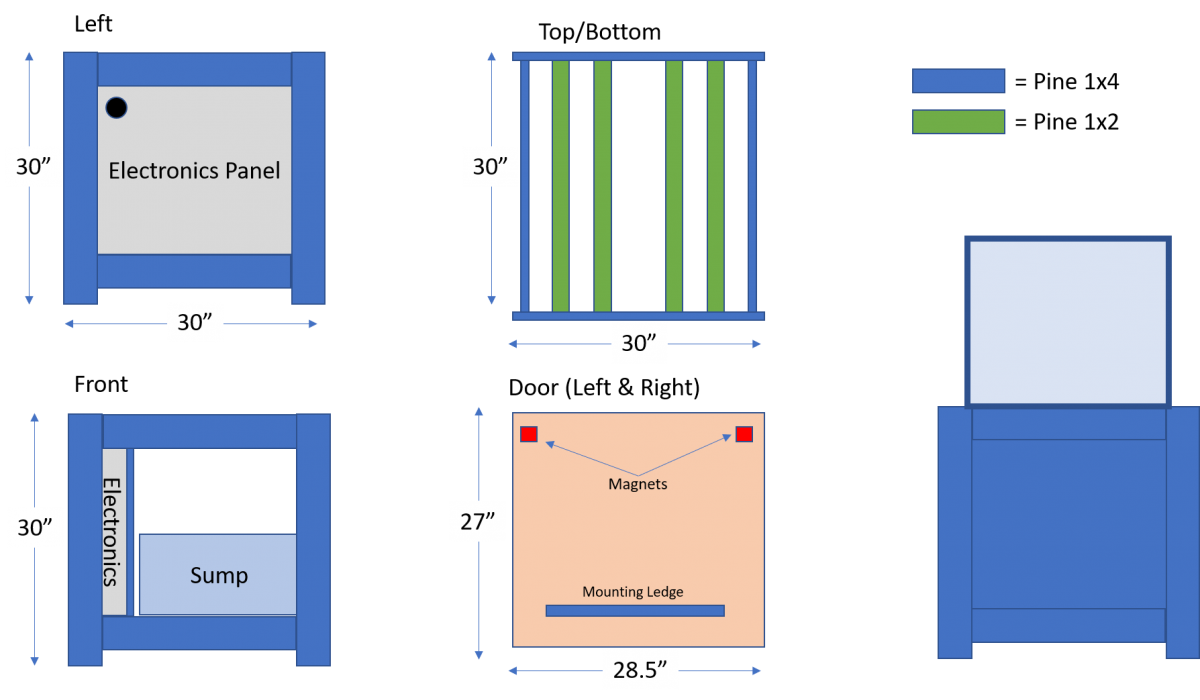

This time around I'm going to do a "dry" electronics section on the left side of the stand. It will be separated from the sump by a piece of plywood (non-structural). I plan to build the stand using 1x4 and 1x2 pine boards with 1/2" plywood for the top, bottom and doors. The doors will be removable on the left, front and right. Only the back wall will be fixed. I plan to hold the doors on with magnets and simple strip to hold it up.

Here's a drawing of my initial concept:

I'm sort of basing the design off of this one that @dbl built. I don't have a fence for my table saw, so I can't do the nice inlay for the joints, but I'm planning to join them with a strip of 1x2.

This time around I'm going to do a "dry" electronics section on the left side of the stand. It will be separated from the sump by a piece of plywood (non-structural). I plan to build the stand using 1x4 and 1x2 pine boards with 1/2" plywood for the top, bottom and doors. The doors will be removable on the left, front and right. Only the back wall will be fixed. I plan to hold the doors on with magnets and simple strip to hold it up.

Here's a drawing of my initial concept:

I'm sort of basing the design off of this one that @dbl built. I don't have a fence for my table saw, so I can't do the nice inlay for the joints, but I'm planning to join them with a strip of 1x2.