Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

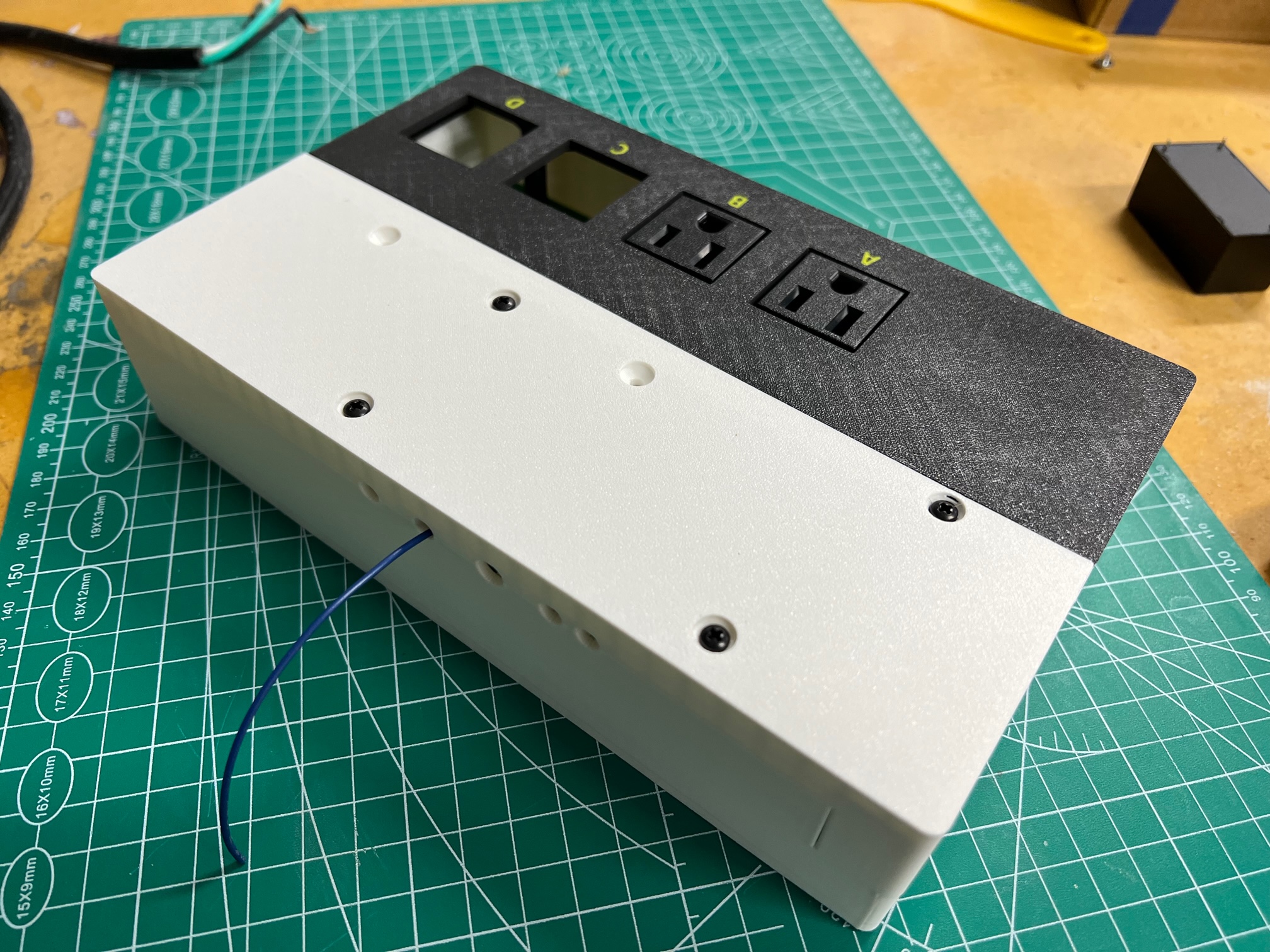

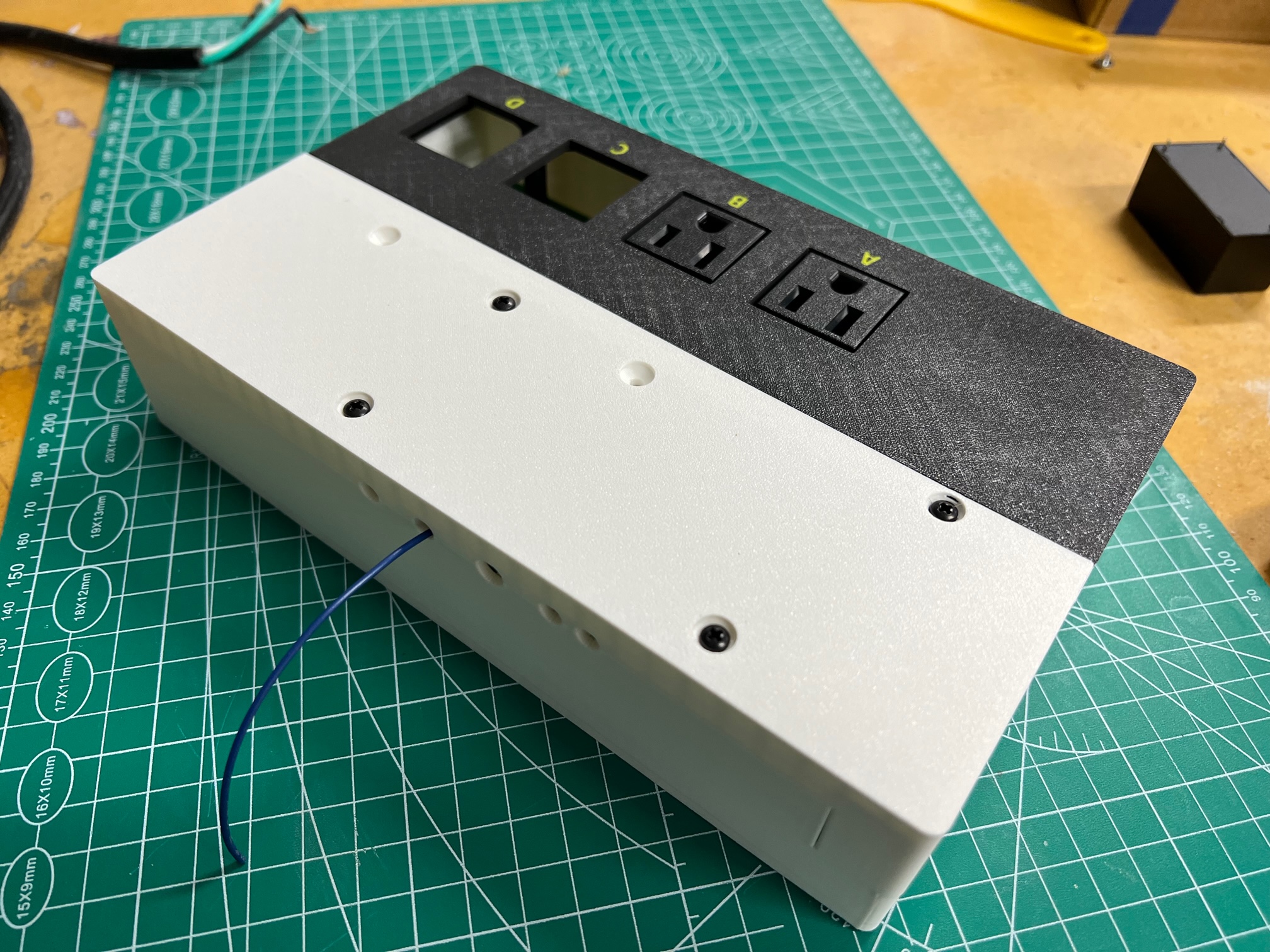

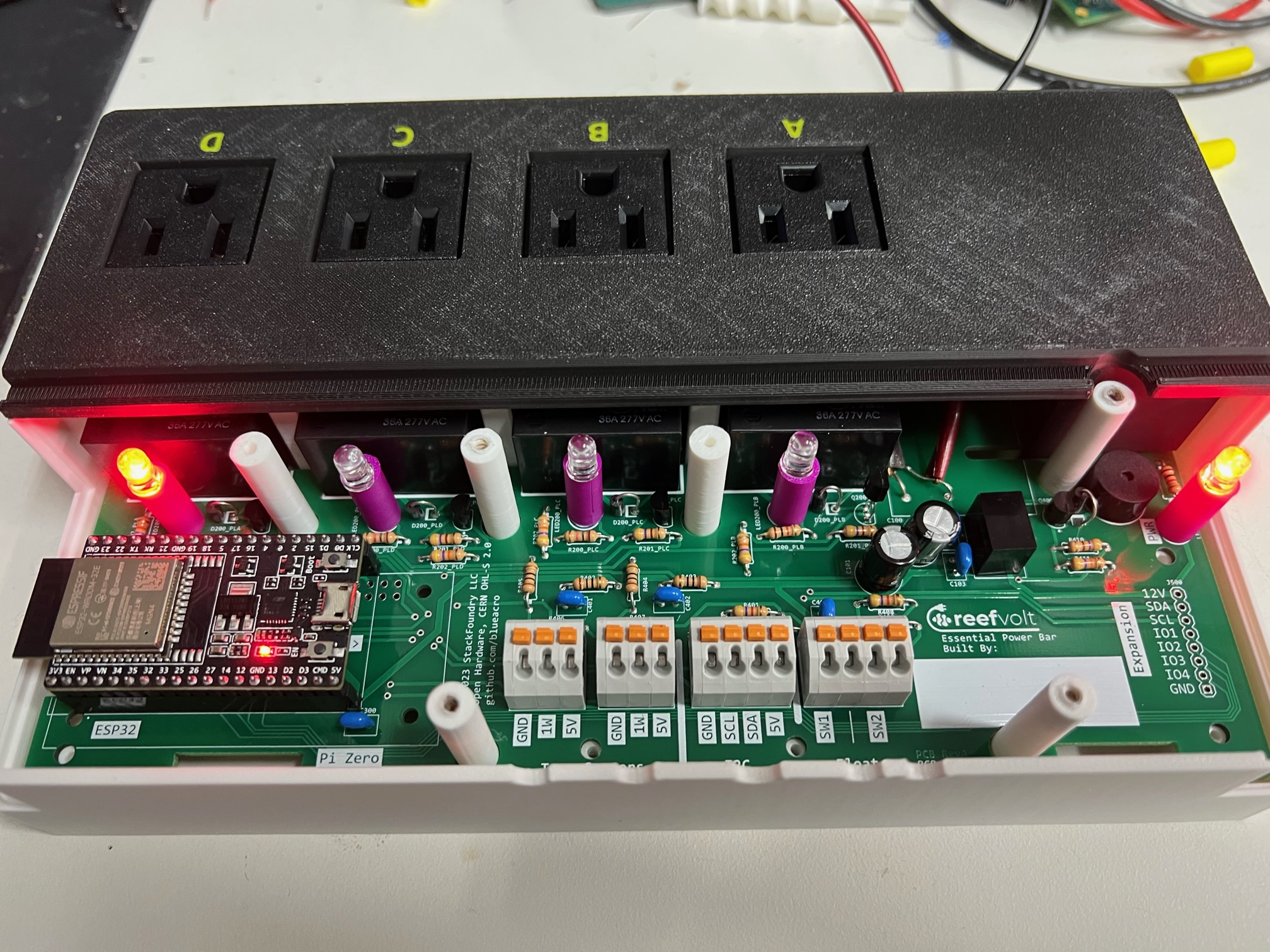

Essential Power Bar - DIY Single PCB design with 3D printed case

- Thread starter theatrus

- Start date

- Tagged users None

How do I download the rv_pwr_es.x_t file?

Honestly, I don't even know how I downloaded the dwg file... it's not intuitive for the way my brain is wired... for sure

No worries, GitHub is a bit weird at times.

On the file in the repo:

reefvolt-essential-power-bar/pcb/parasolid_dxf/rv_pwr_es.x_t at main · blueacro/reefvolt-essential-power-bar

DIY Power Bar Design Files. Contribute to blueacro/reefvolt-essential-power-bar development by creating an account on GitHub.

Click on download on the right side of the page

For some reason, I didn't see that... haha

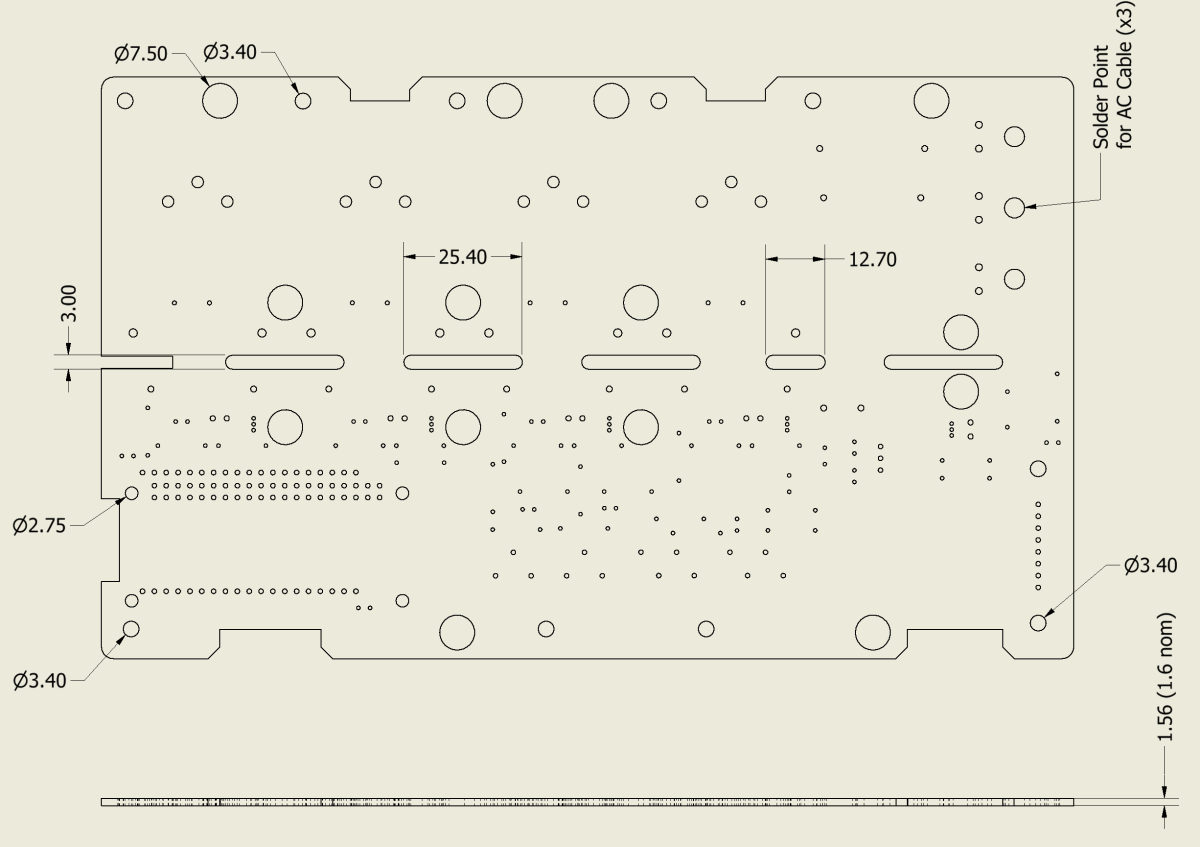

Meh. If you can give me the size of the holes and which ones are intended for securing the case with screws.

Or even better, what the purpose is for he holes in the pcb?

Or even better, what the purpose is for he holes in the pcb?

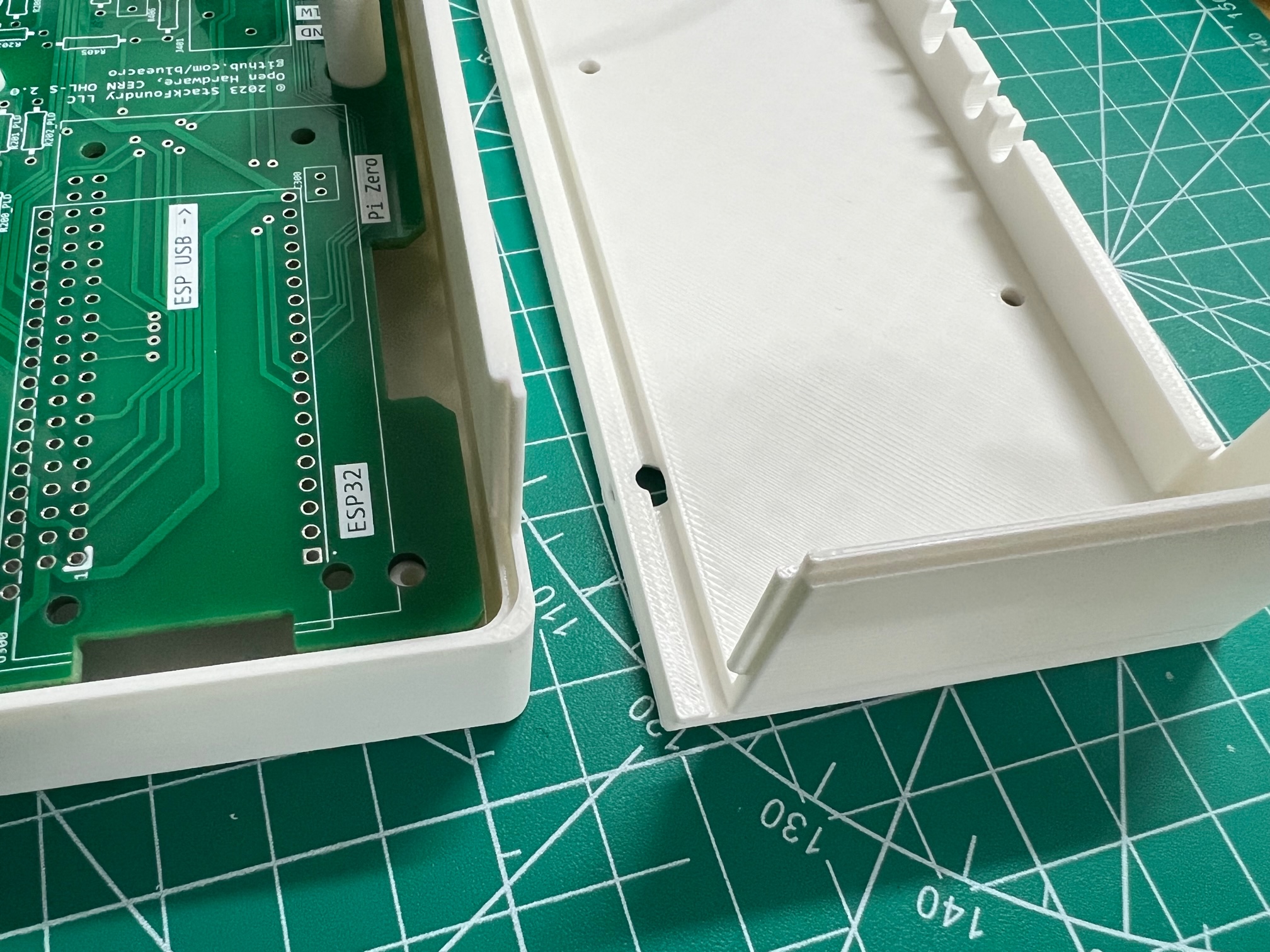

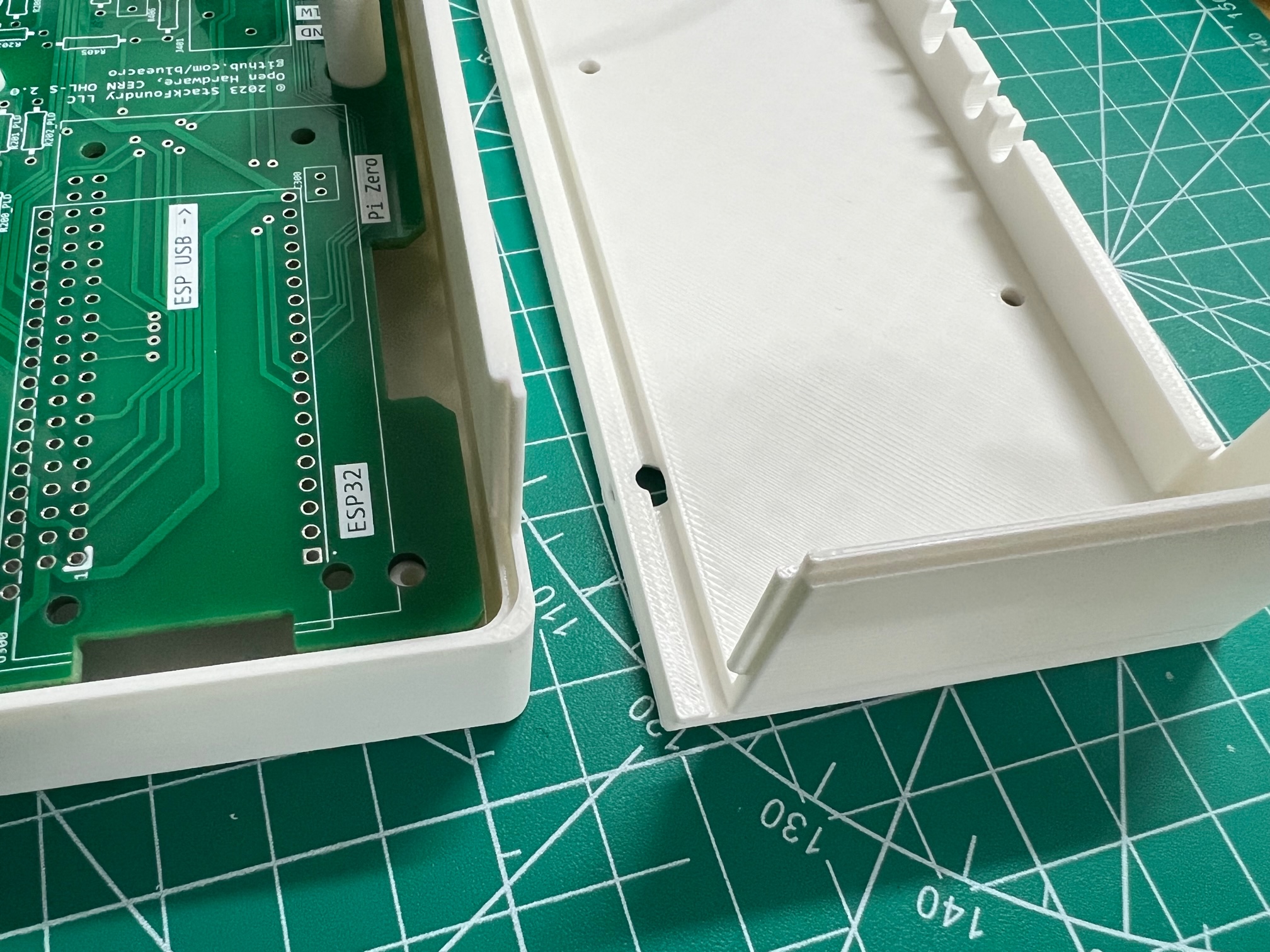

Two critical hole sizes: 3.4mm (for board to case) and 7.5mm (for case supports). Holes are metric as most PCB shops only use metric drills (and the rest of the board dimensions are imperial sized for entertainment value). The Raspberry Pi Zero uses an M2.5 standoff to mount to the board, but not to the case. Screws should be #4 or M3 for plastic somewhat interchangeably.

I added step files of the whole thing and just the board: https://github.com/blueacro/reefvolt-essential-power-bar/tree/main/pcb/step

Also added Gerber files for RevA.

Doing some hole auditing work, I'm pretty sure there will be a RevB - some of my holes aren't even grid aligned because of operator failure, and that bothers me. And other misc cleanups (like too many bosses for the case to hold together really, I just went wild where there was space).

I added step files of the whole thing and just the board: https://github.com/blueacro/reefvolt-essential-power-bar/tree/main/pcb/step

Also added Gerber files for RevA.

Doing some hole auditing work, I'm pretty sure there will be a RevB - some of my holes aren't even grid aligned because of operator failure, and that bothers me. And other misc cleanups (like too many bosses for the case to hold together really, I just went wild where there was space).

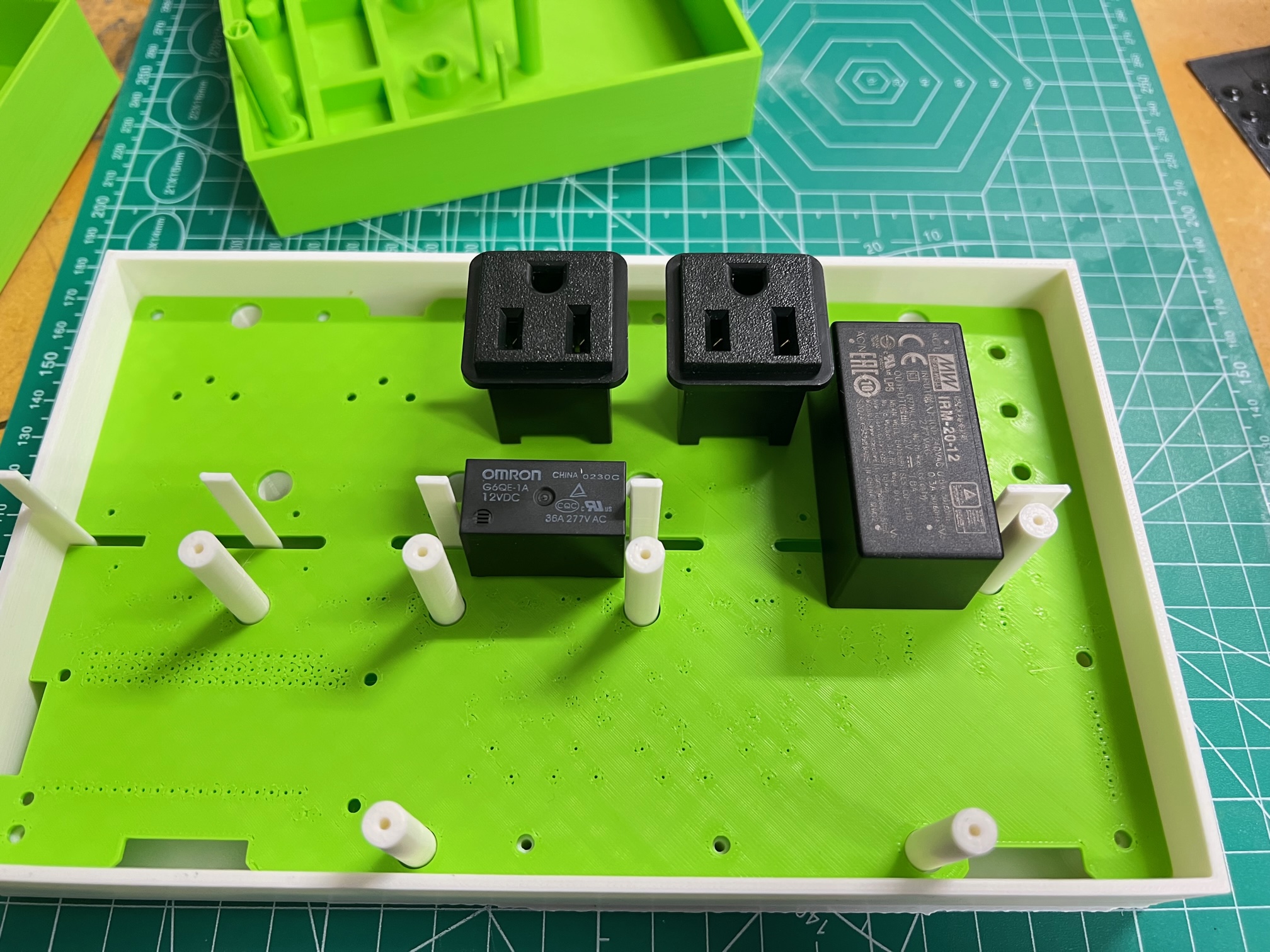

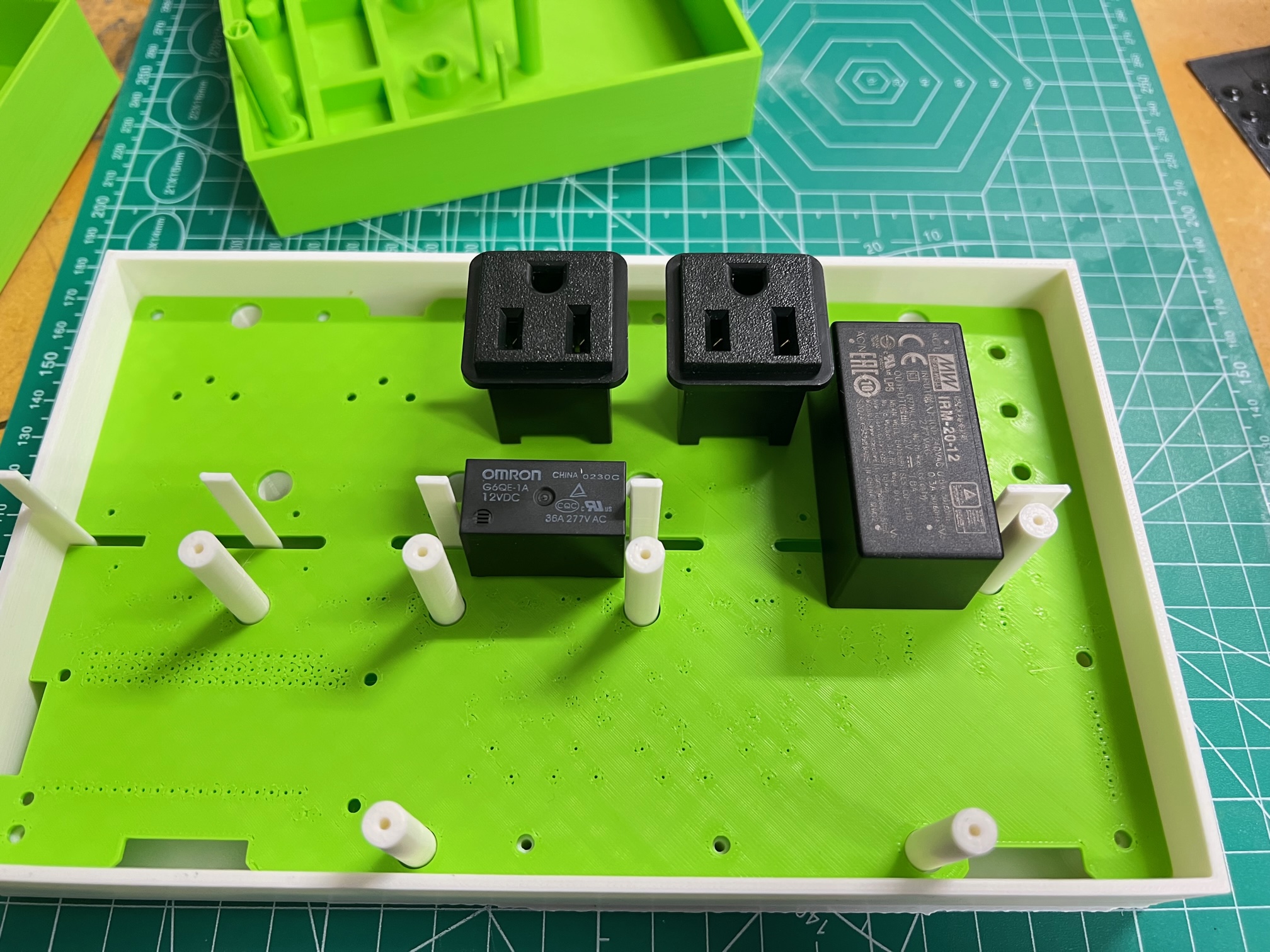

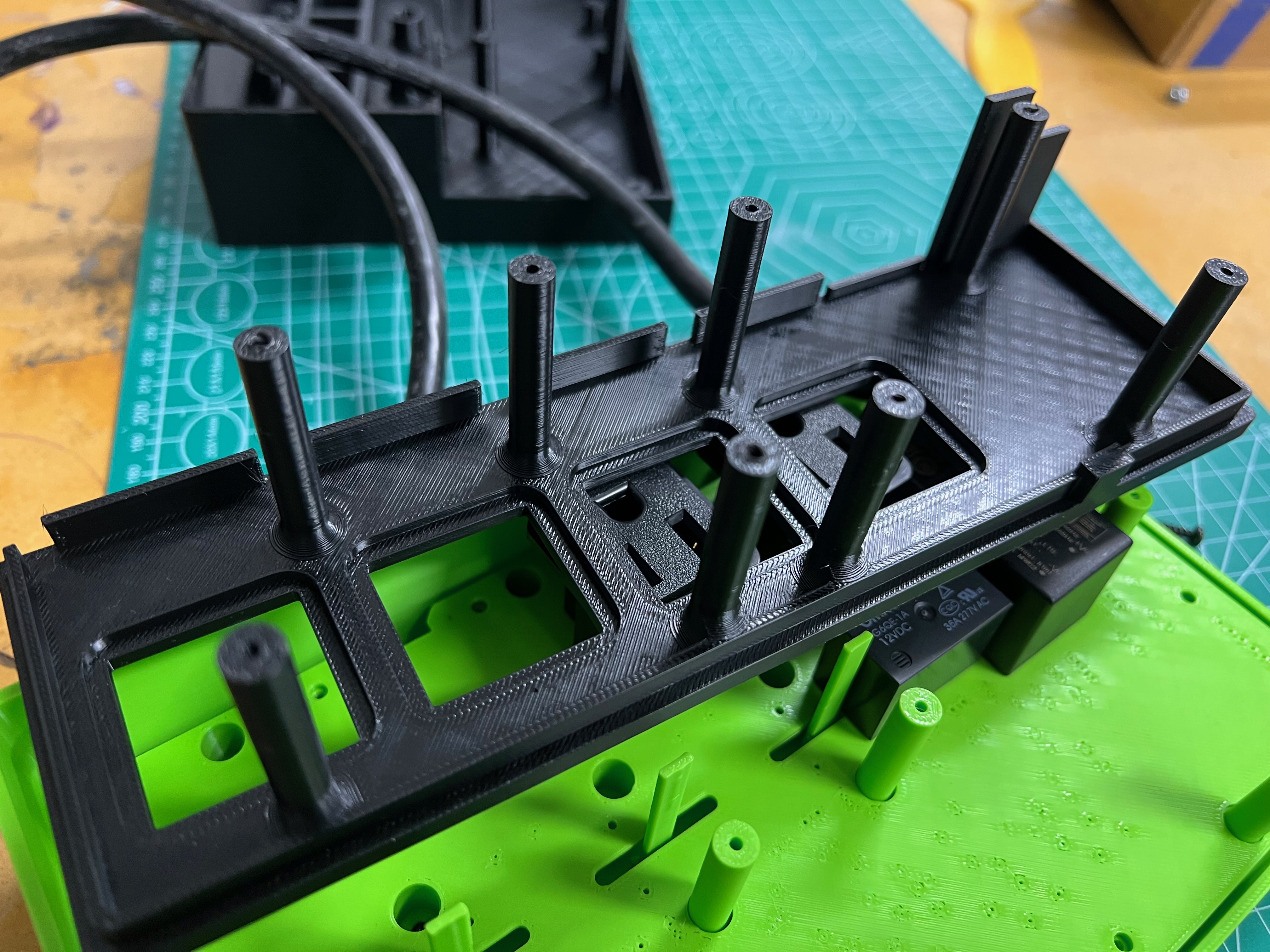

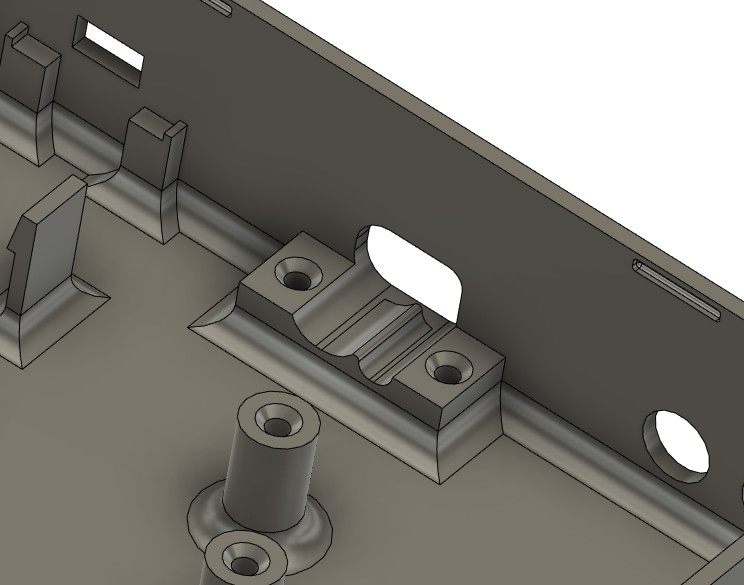

While I was looking at the board, I decided to print a mock PCB. Actually surprisingly useful for component fit checks! Also, I somehow lost all my PCB clearance when I added the walls ... oops. Added that back into the model.

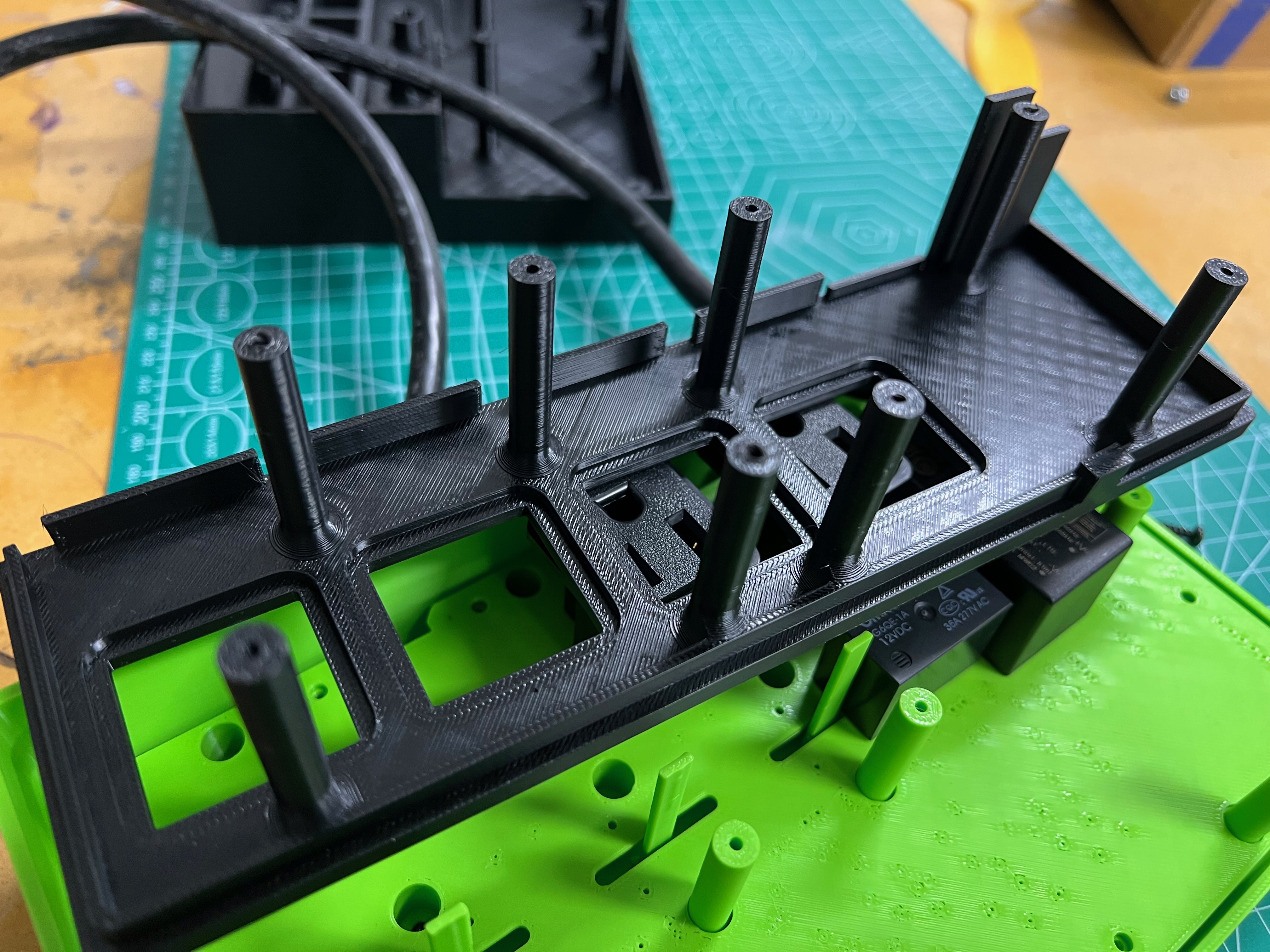

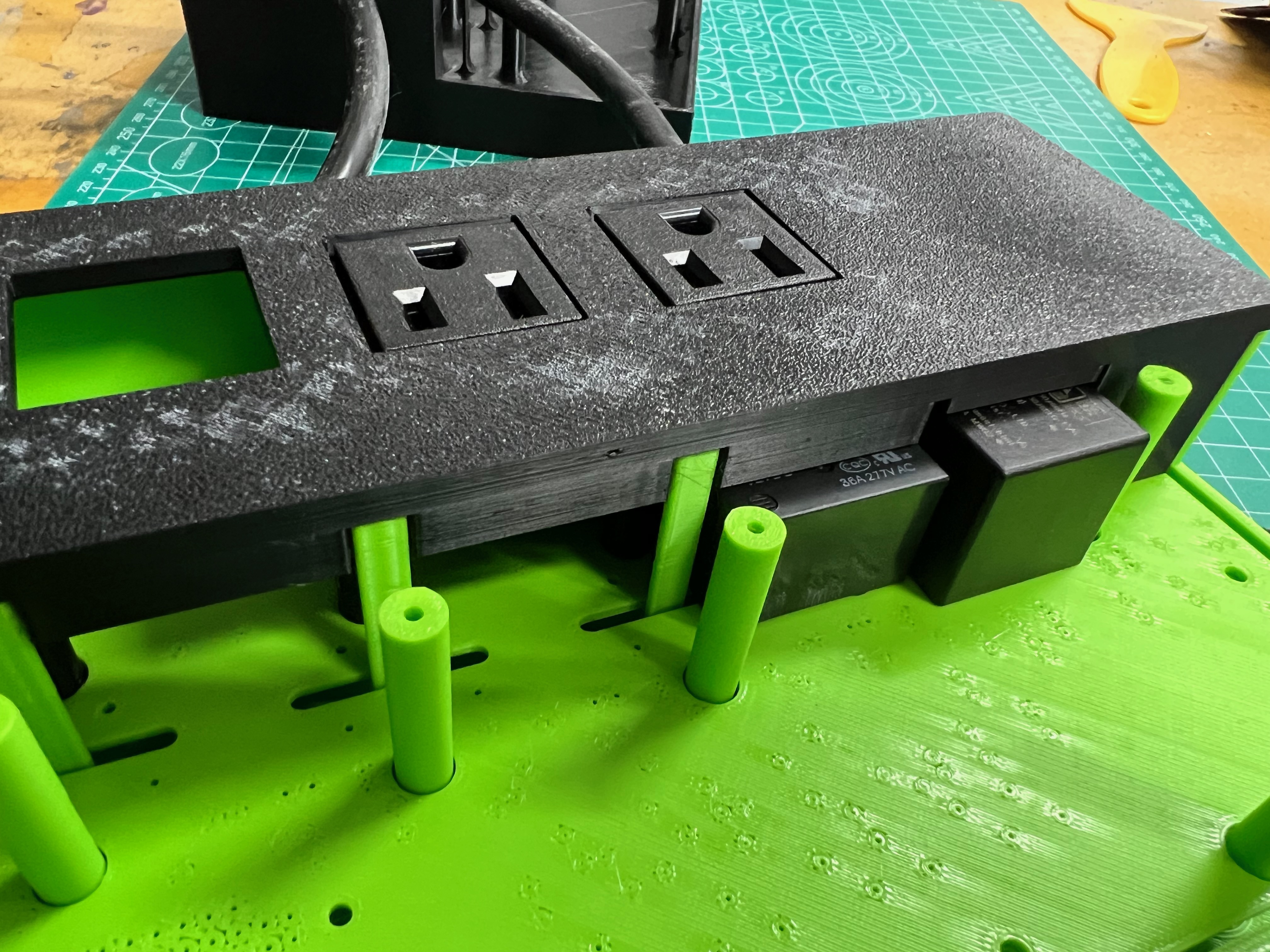

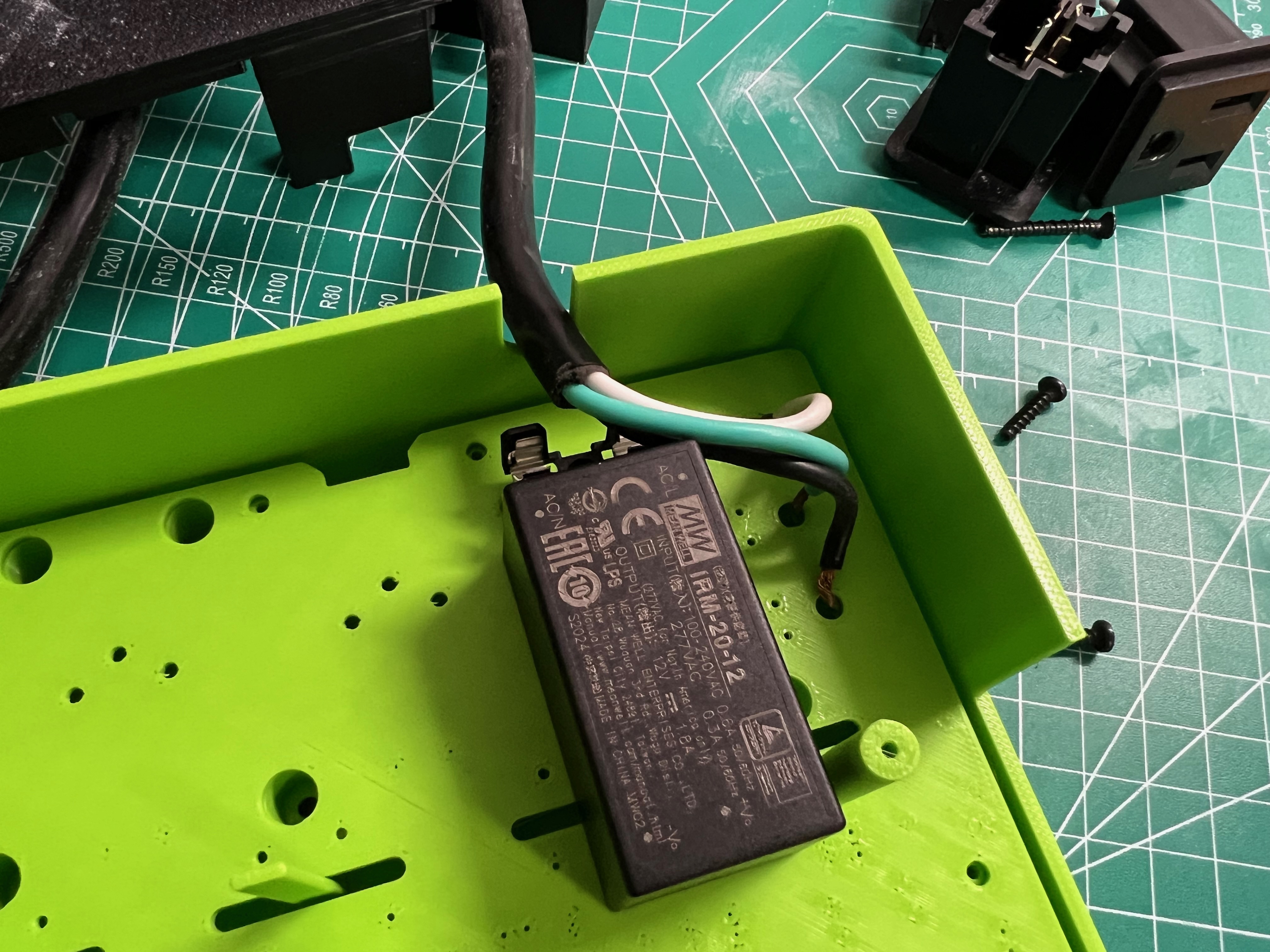

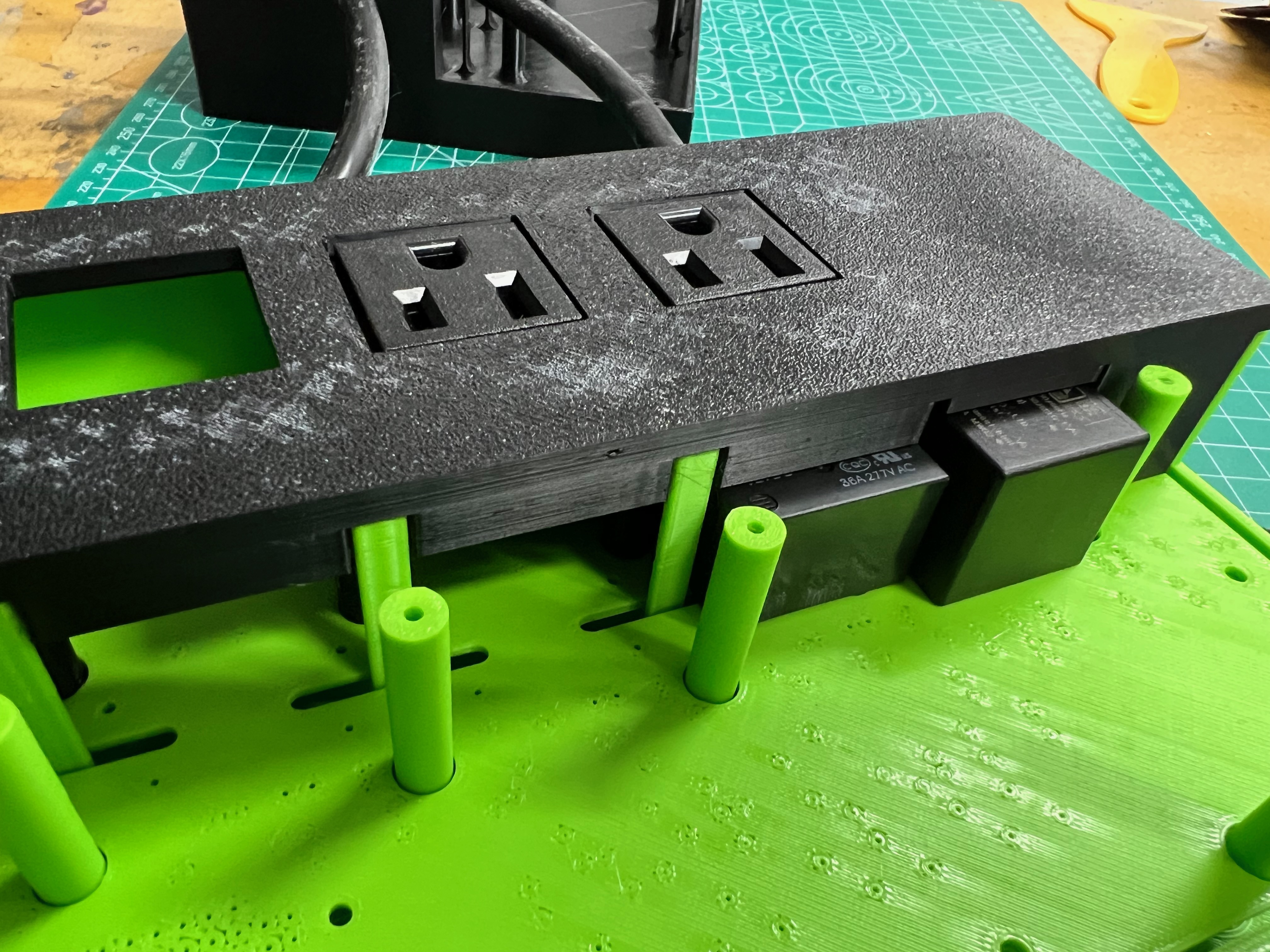

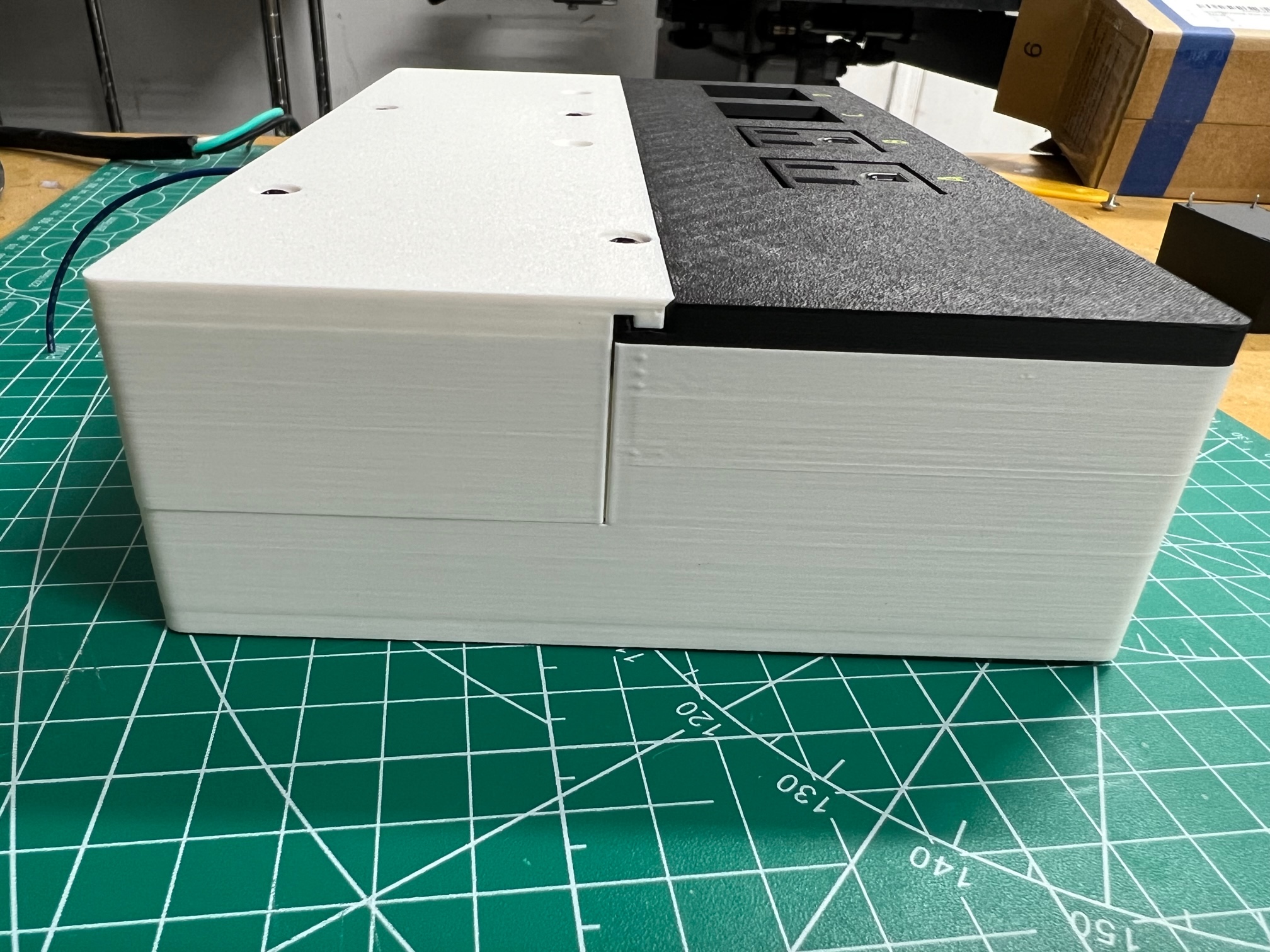

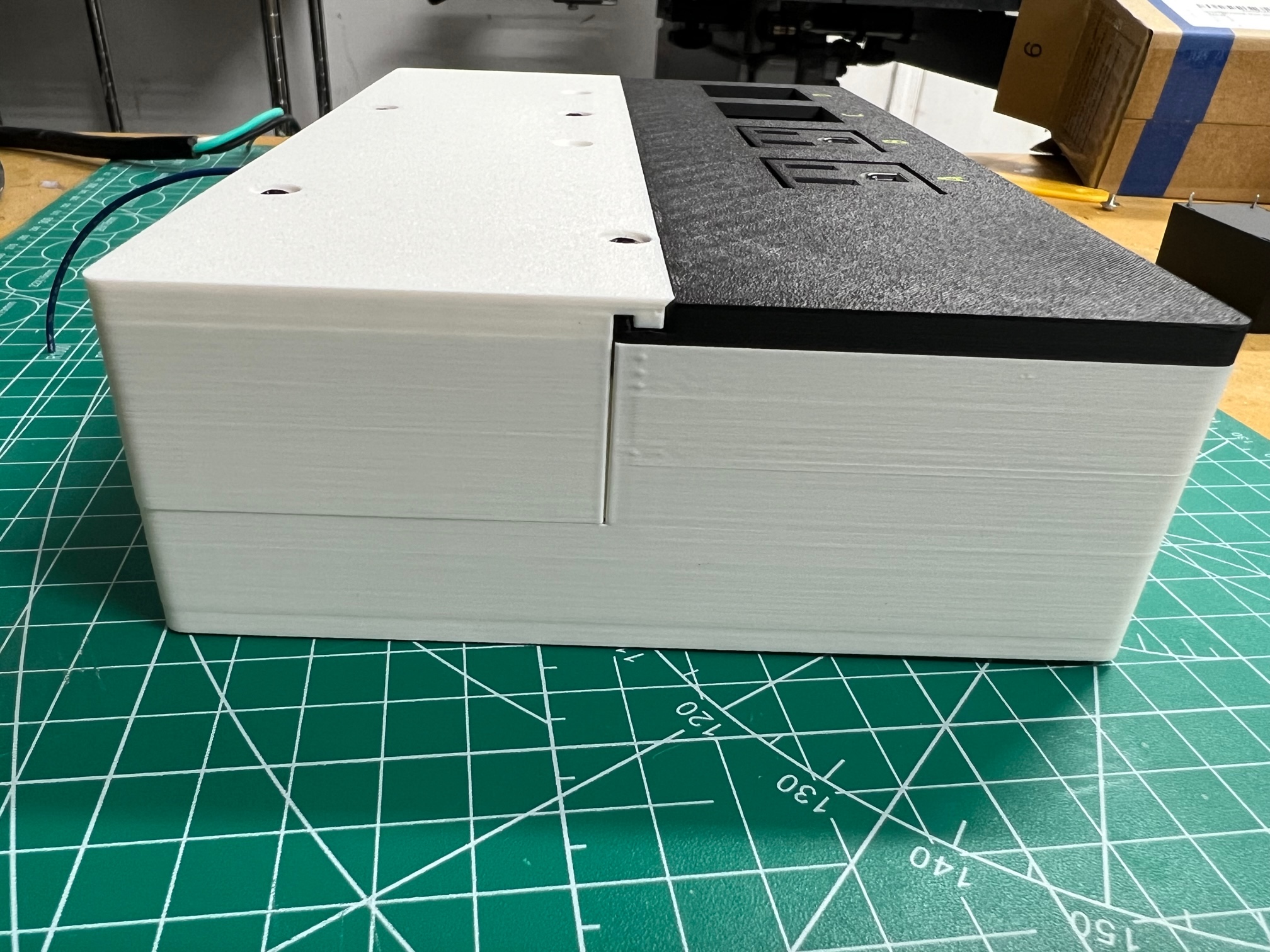

Waiting on the PCBs still (maybe today), so I messed with a bit more of the case design. Printed the top shell of the high voltage section:

I tried a new build plate (textured PEI), which looks pretty good except for the black ABS getting white splotches.

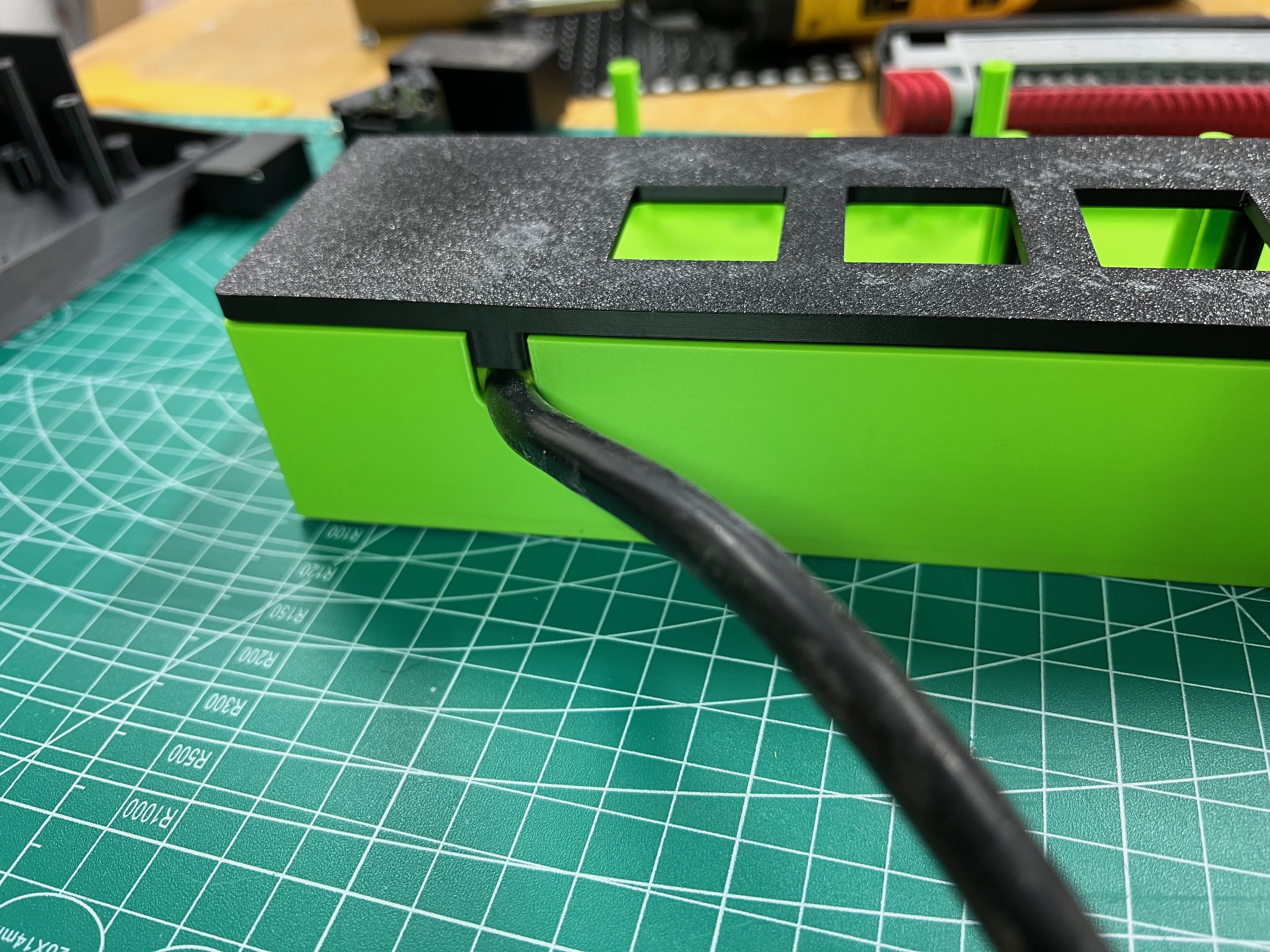

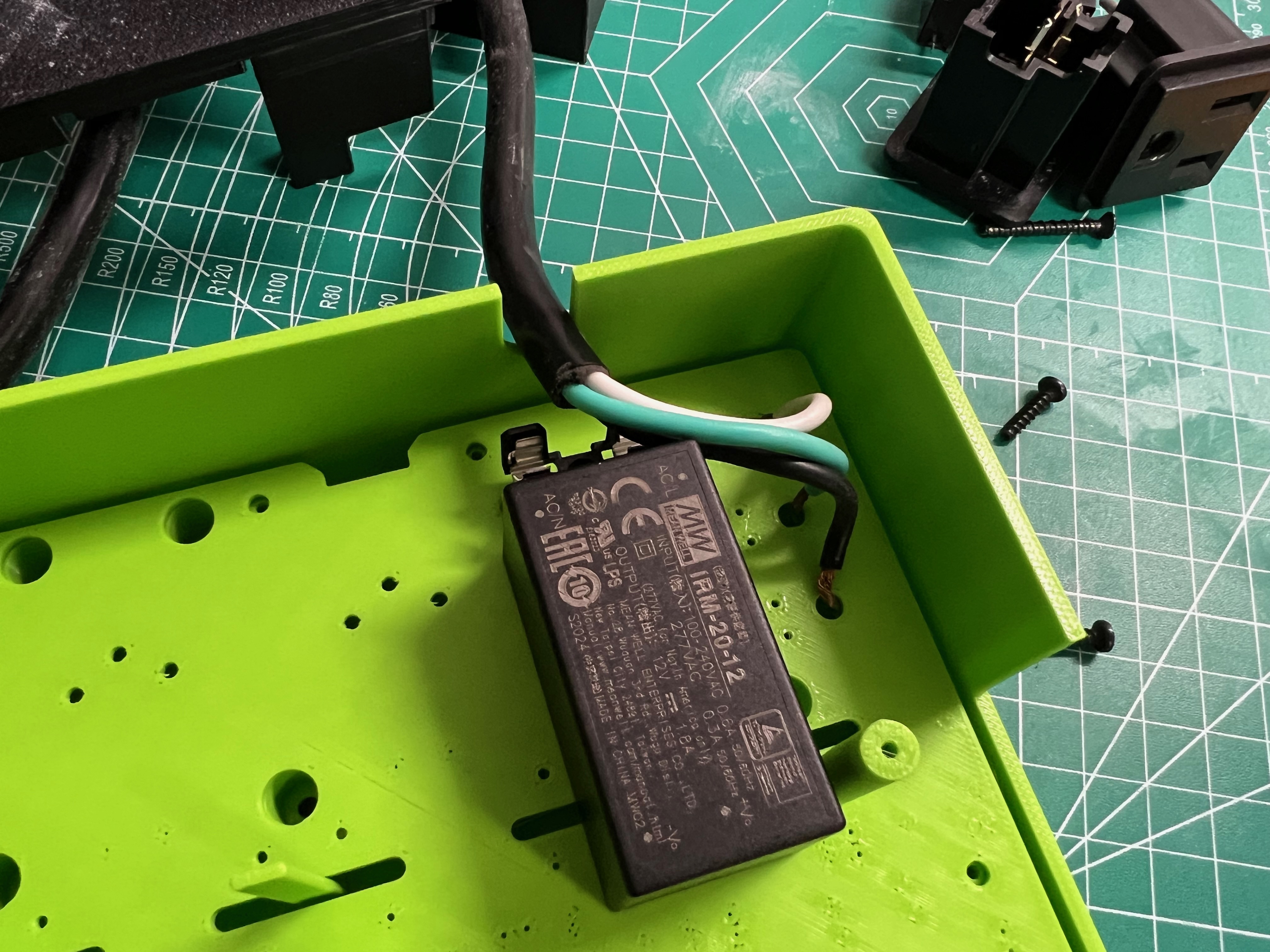

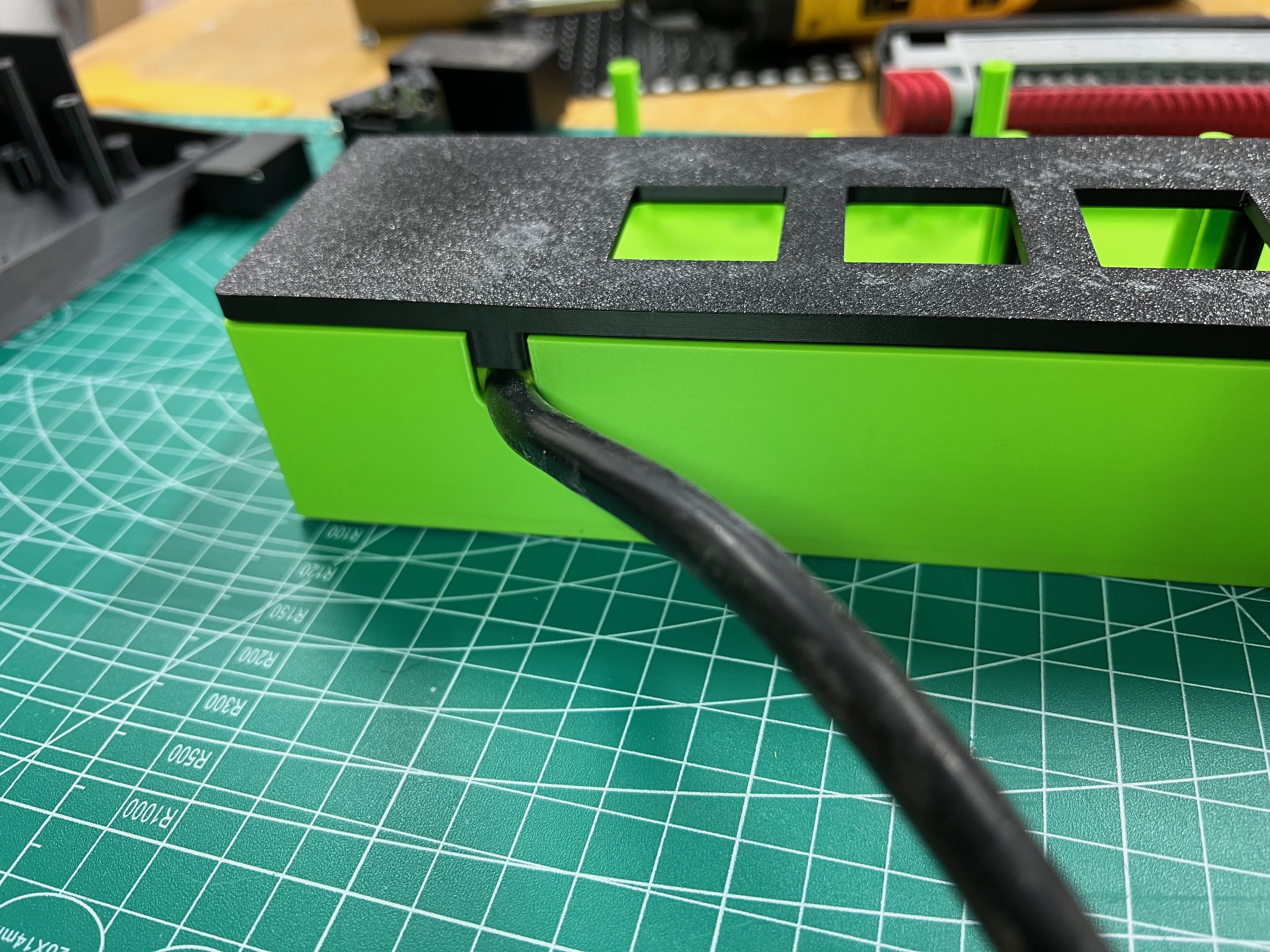

This is the current thought on AC input cable routing - I need to do a bit more work to clamp on the cable, maybe an adjustable slide in shim.

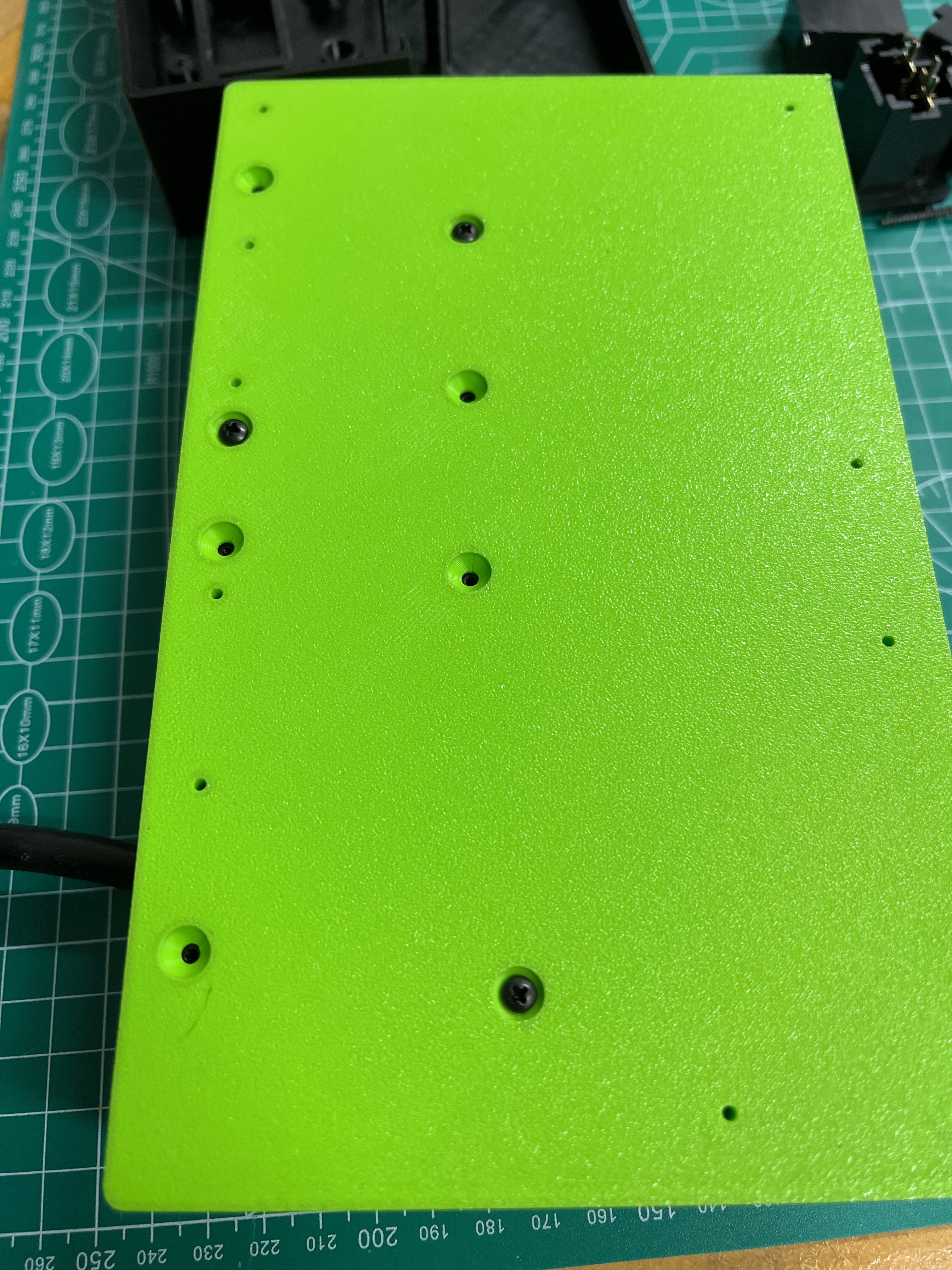

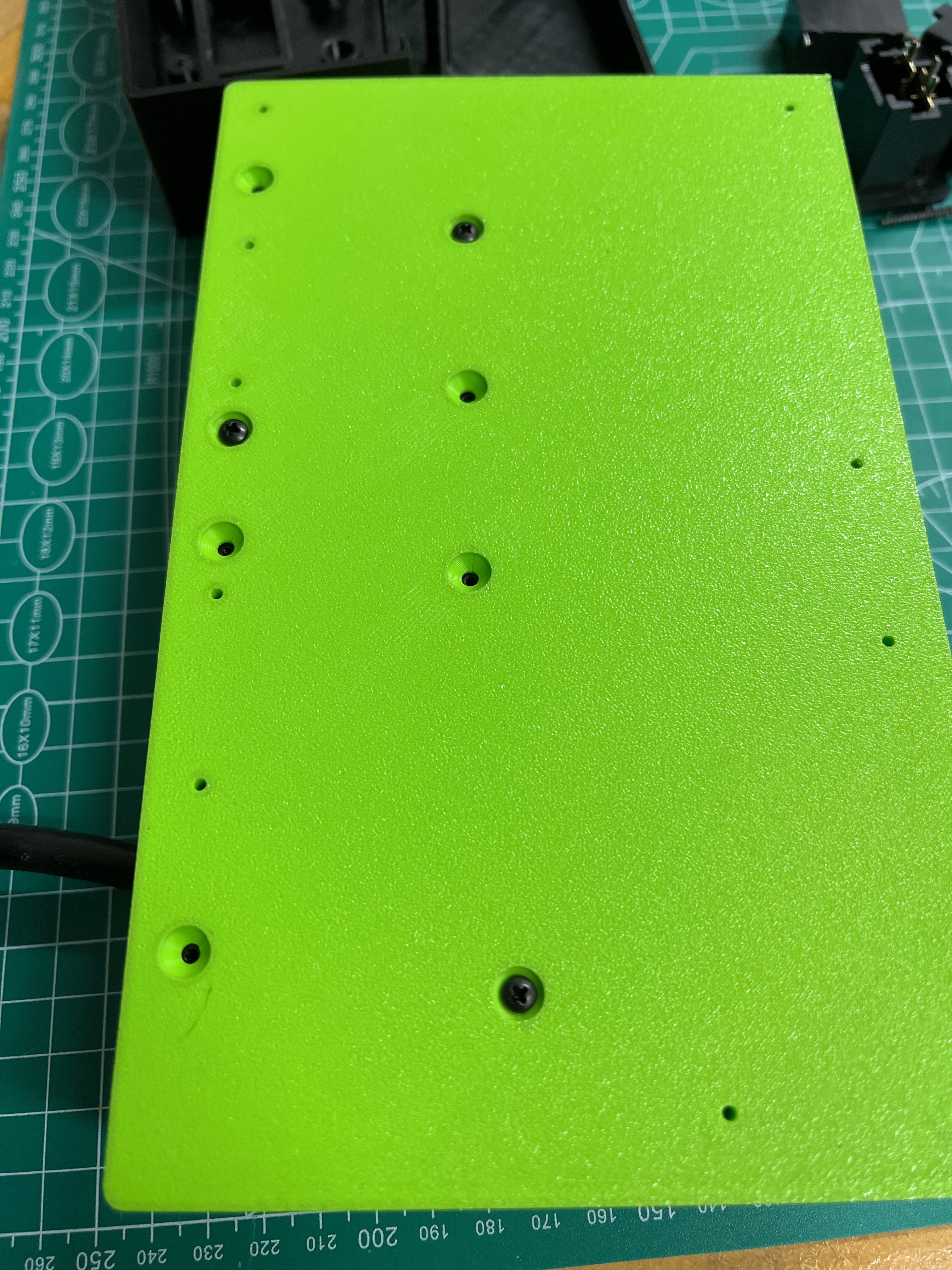

The textured plate looks decent on colored (PLA). Screws go in nicely to the top HV plate (I didn't install them all). Maybe needs a few stick on feet for the finished look.

I tried a new build plate (textured PEI), which looks pretty good except for the black ABS getting white splotches.

This is the current thought on AC input cable routing - I need to do a bit more work to clamp on the cable, maybe an adjustable slide in shim.

The textured plate looks decent on colored (PLA). Screws go in nicely to the top HV plate (I didn't install them all). Maybe needs a few stick on feet for the finished look.

Very nice... u haven't had much time to play with a case design.

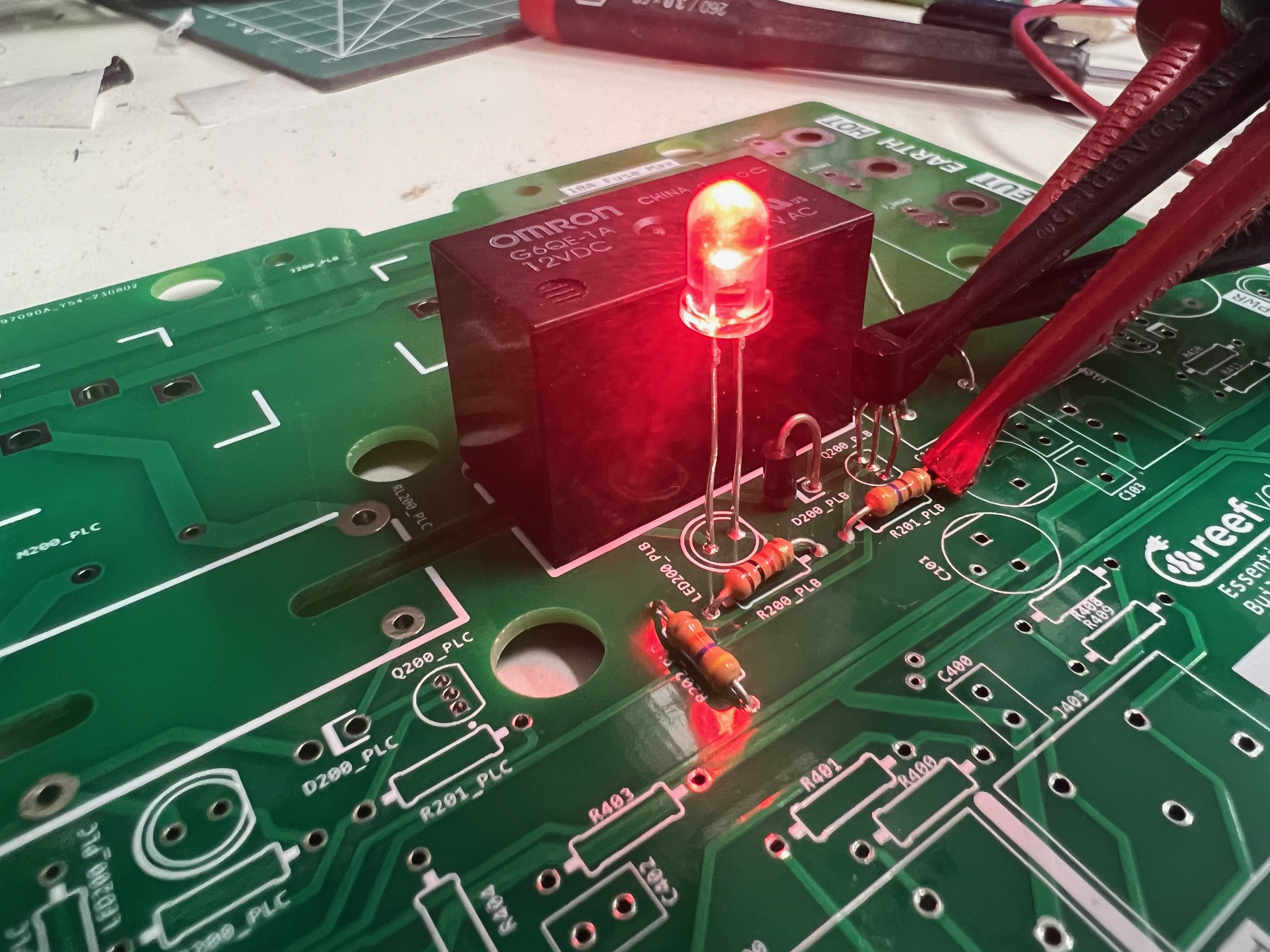

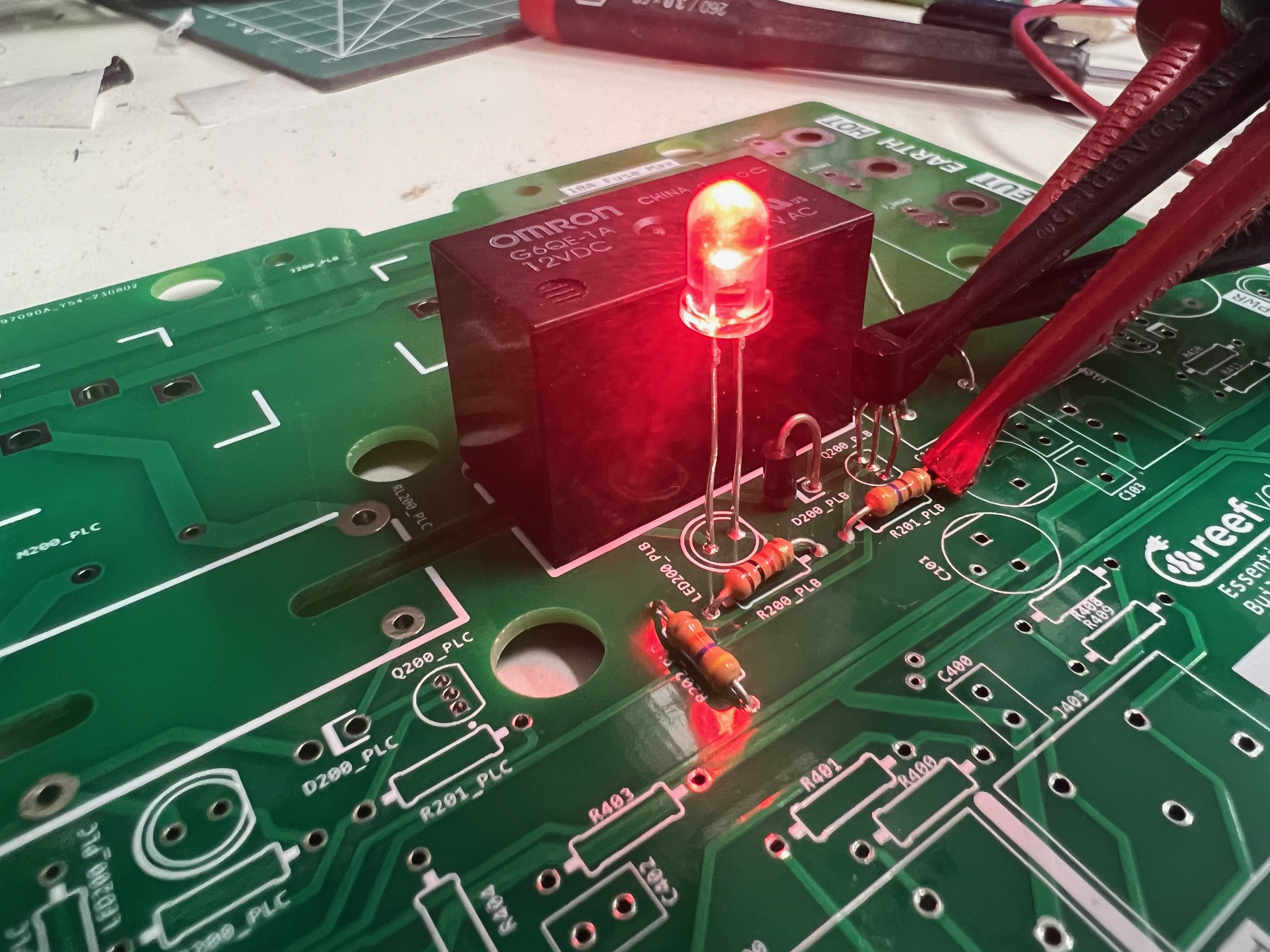

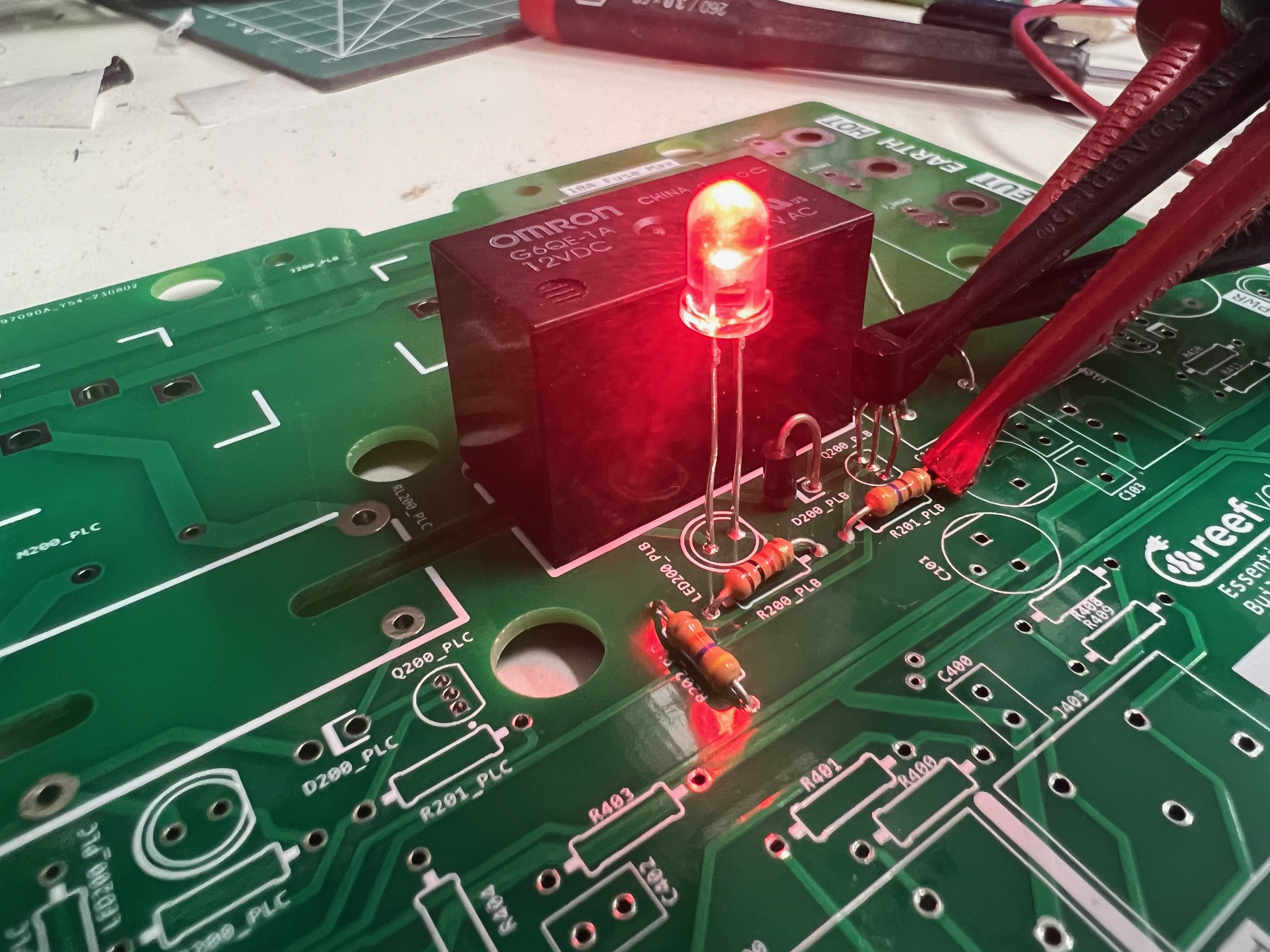

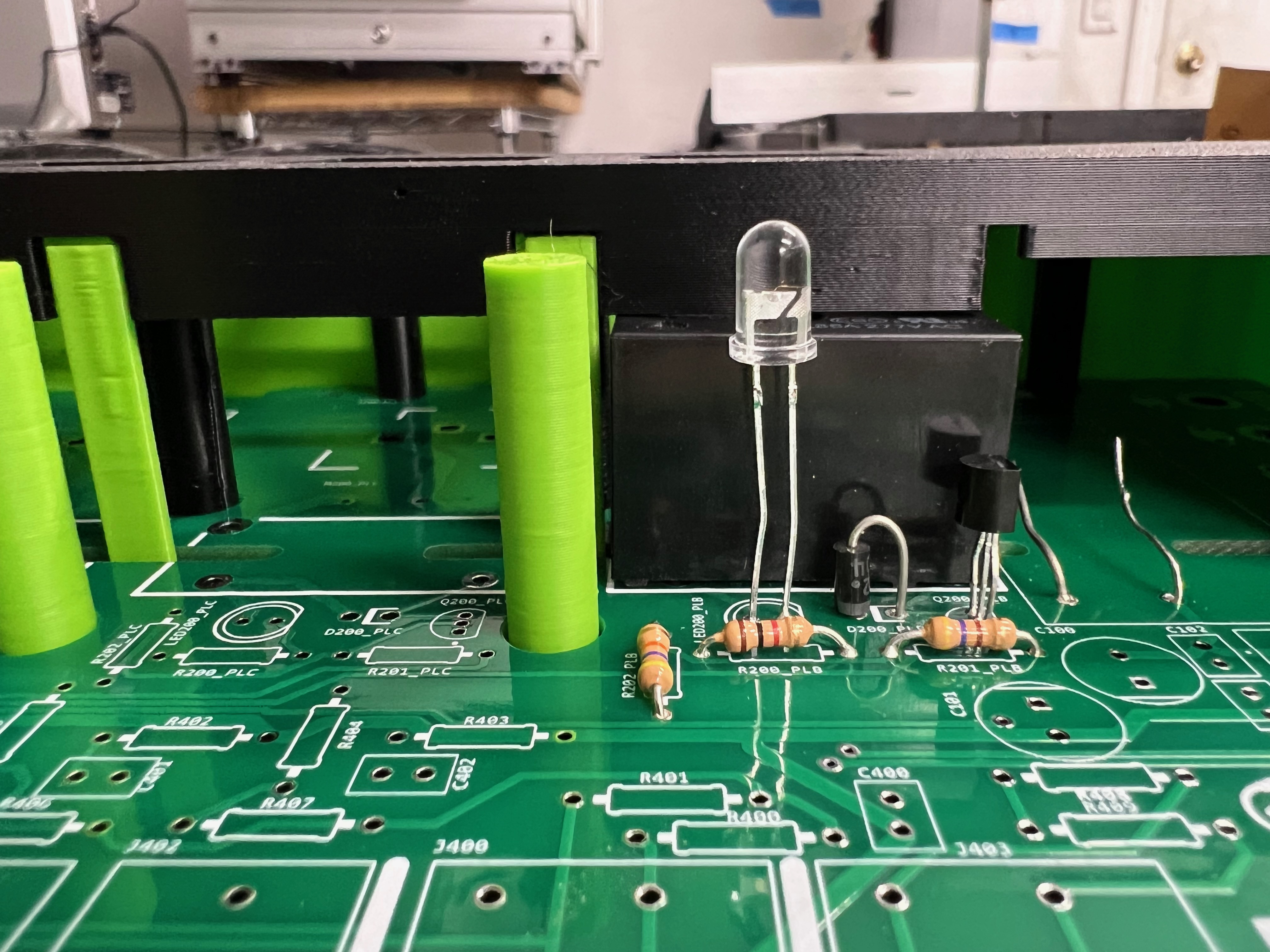

Did a quick build of one relay channel just to check the part suitability. Of course, the first one I built, the diode ended up backwards, and then I melted the switch transistor by dumping an amp through the poor 2n4401.

Not used to needing a solder sucker gun because I don't do much through hole parts, but was easy enough to swap.

First off, the on LED is bright. I may reduce the current to it further.

The other good news is an average LED legs seem juuust long enough to go to the top case. While I don't want too many holes in the case, it would be nice if the on LEDs were visible. Need to think on this one (maybe some snap in thin white plastic over the LED? Translucent PETG?)

Tertiary note is the relay is loud - its chonky inside and isn't a soft click. Don't use this for a wavemaker and old school pumps.

Not used to needing a solder sucker gun because I don't do much through hole parts, but was easy enough to swap.

First off, the on LED is bright. I may reduce the current to it further.

The other good news is an average LED legs seem juuust long enough to go to the top case. While I don't want too many holes in the case, it would be nice if the on LEDs were visible. Need to think on this one (maybe some snap in thin white plastic over the LED? Translucent PETG?)

Tertiary note is the relay is loud - its chonky inside and isn't a soft click. Don't use this for a wavemaker and old school pumps.

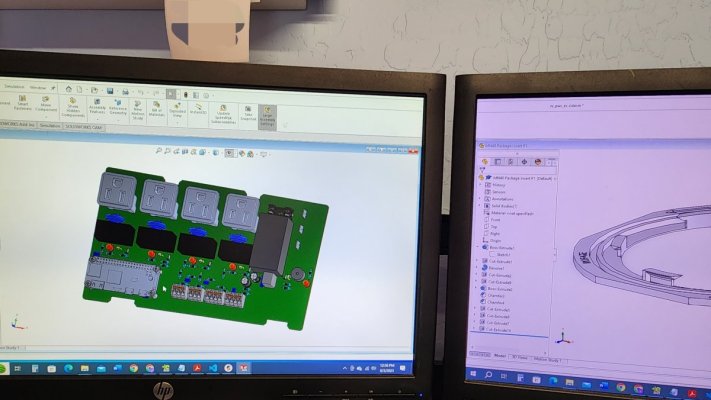

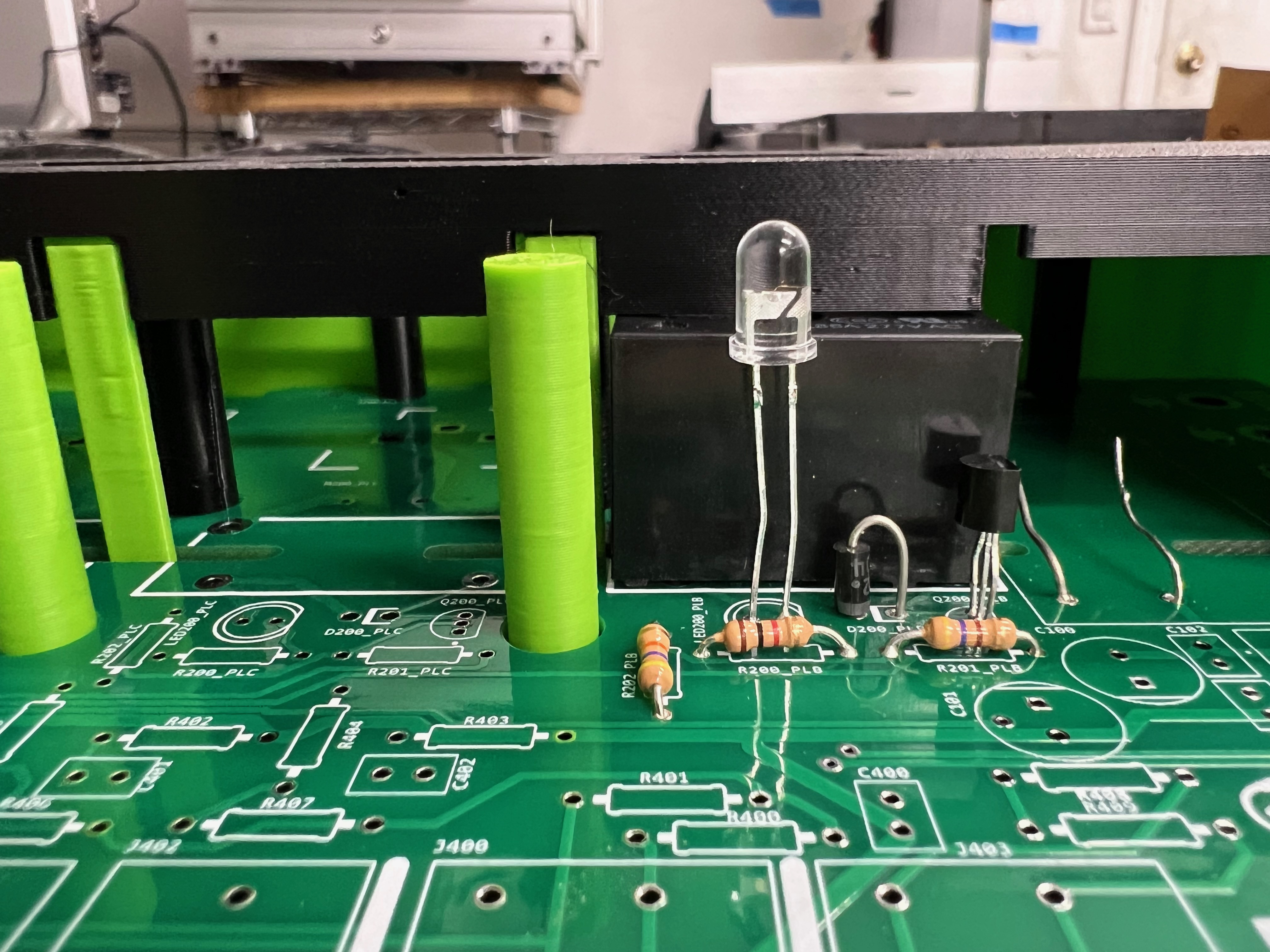

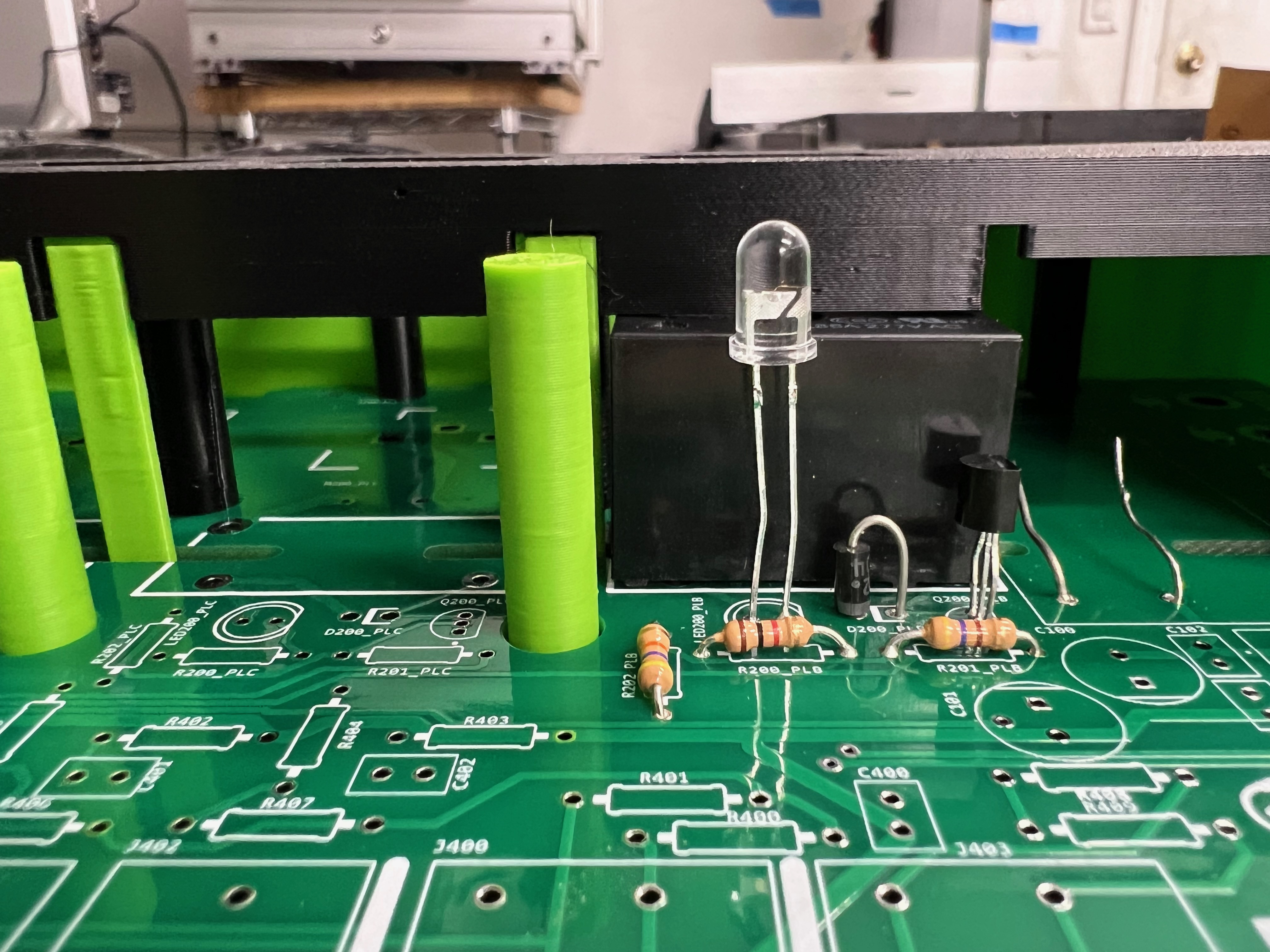

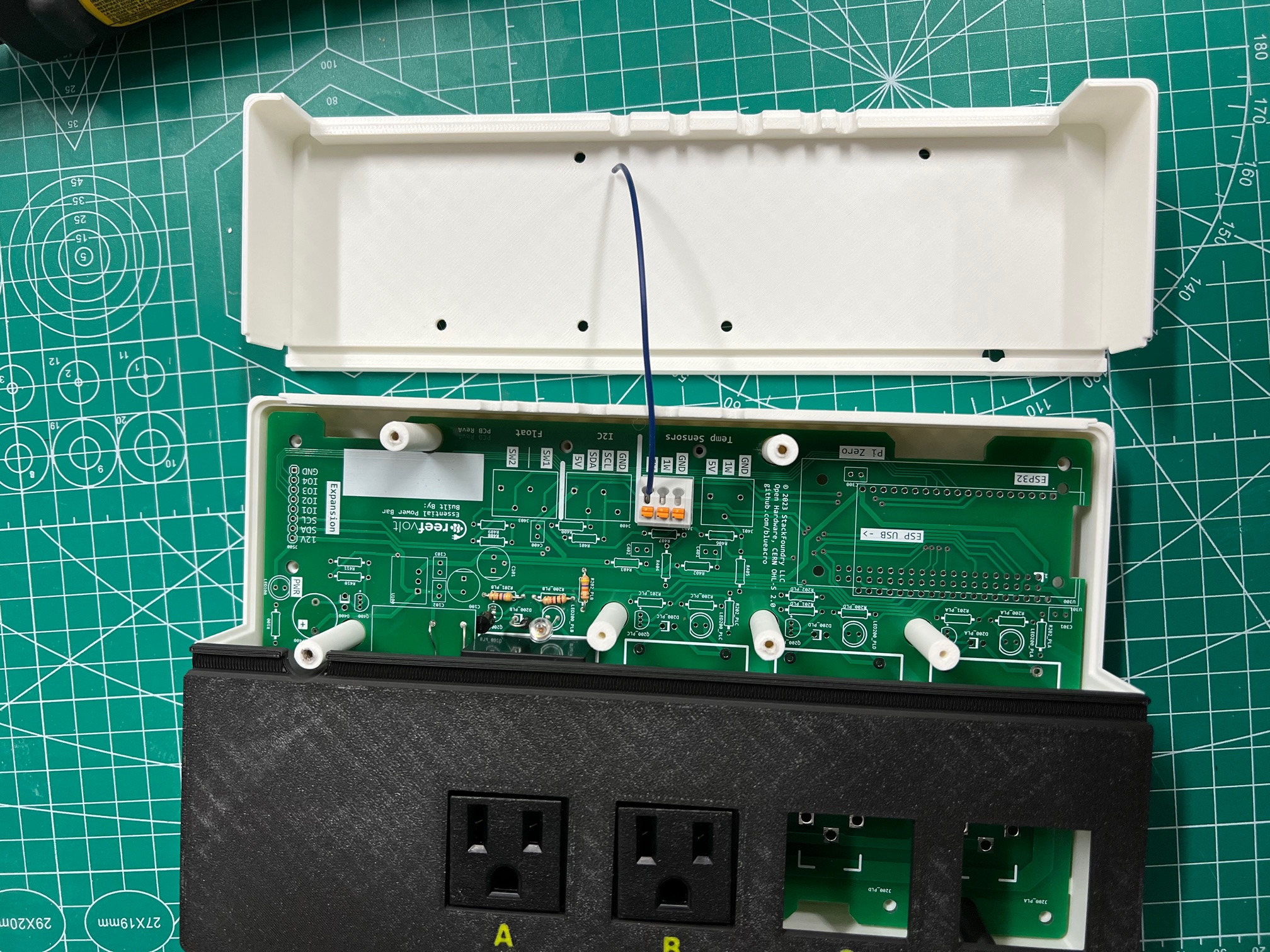

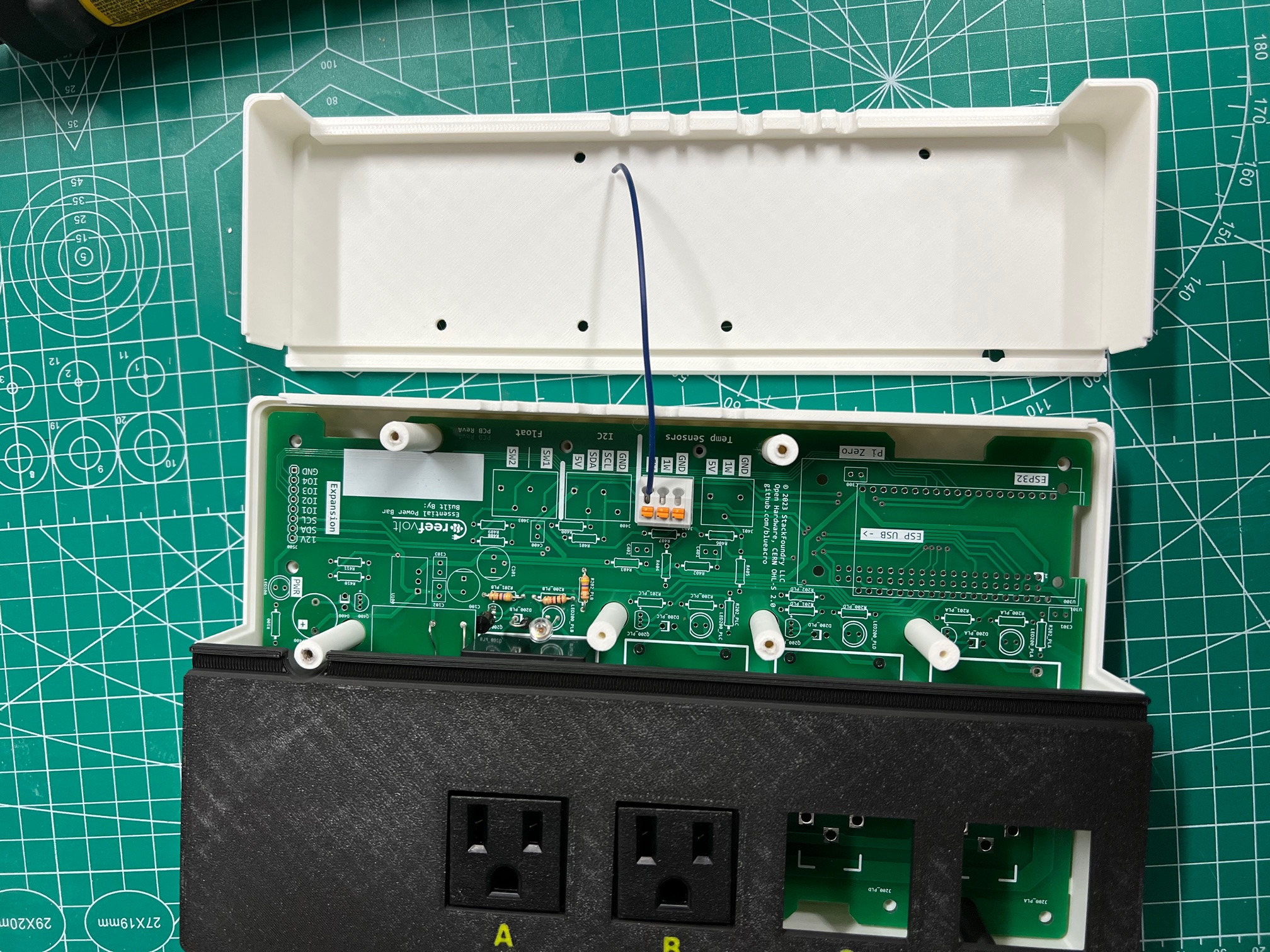

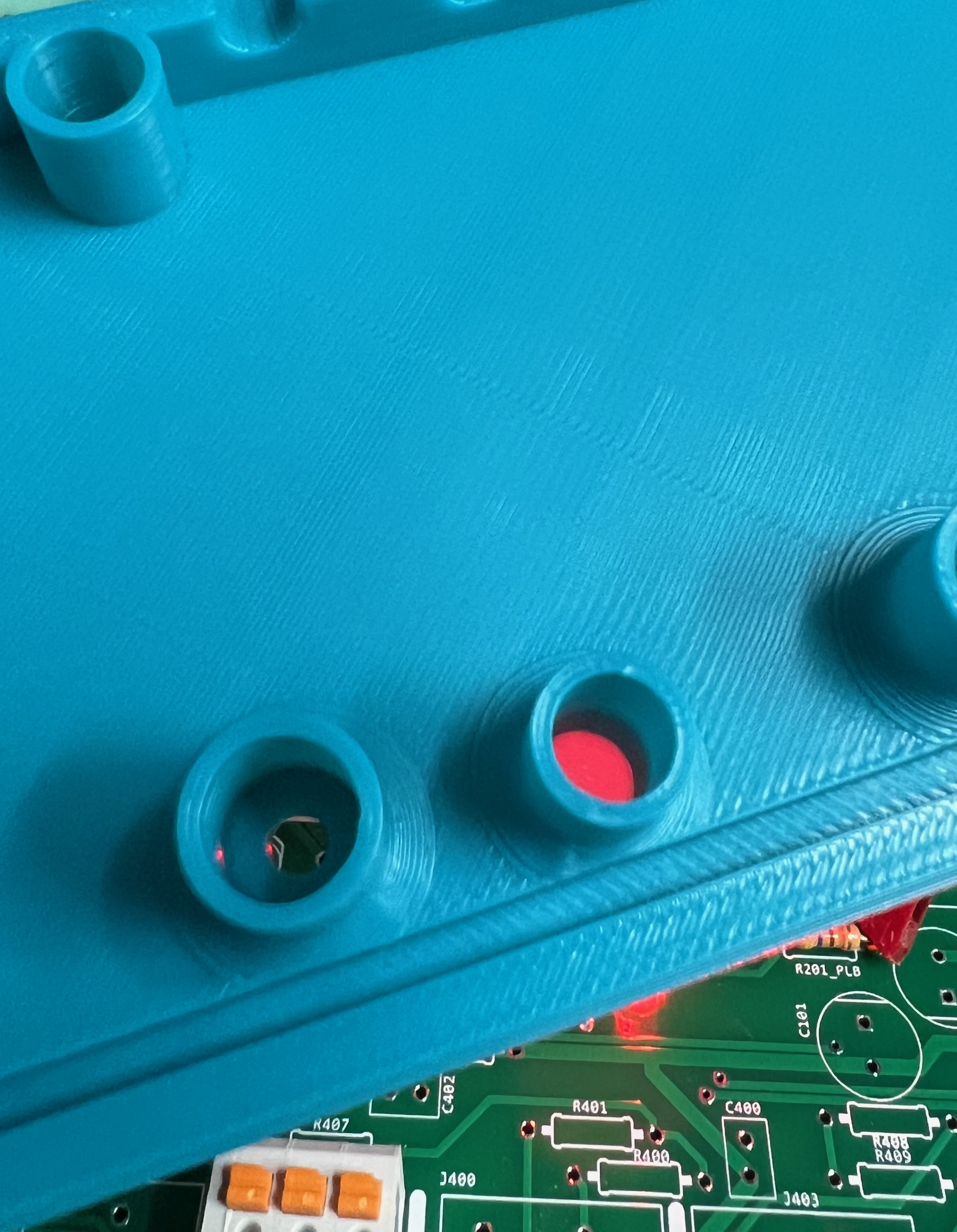

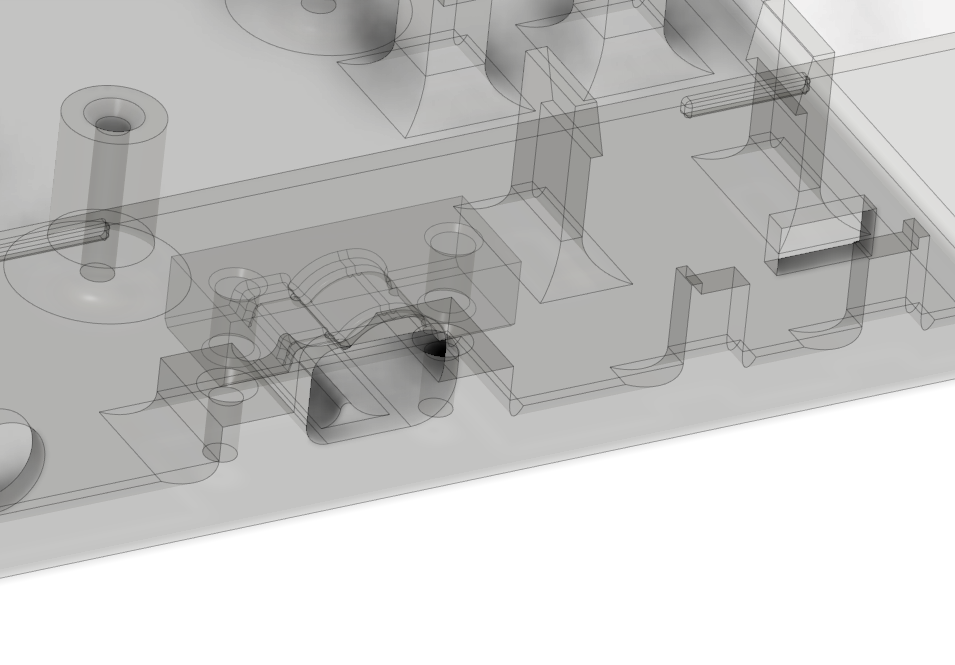

Picture dump - doing some iterative refinement, finding broken references in CAD, and fleshing out the rest of the case work. I have the top of the "low voltage" (LV) side modeled. I experimented using an inlay layer while printing (the Bambu with the AMS switches filaments a few times doing this), which leads to some nice looking outlet labels

Case files: https://github.com/blueacro/reefvolt-essential-power-bar/tree/main/case

On an enhancement note, its probably pretty easy to add one of those small 1" OLED modules to the top case for displaying sensor values. The I2C bus is there, but I didn't give an easy header for 3.3V power or a secondary regulator. Can be tweaked.

Some other pending notes:

- I still want to experiment with the LEDs shining through the top of the case.

- The bottom of the case does not have holes for the Pi Zero ports to be accessible. It needs a variant to make that happen.

- I opted for holes to feed cables through to add some amount of moisture ingress protection. Maybe need to print some plugs for unused holes.

- Screws on top, are not unexpectedly, kinda ugly. I may reduce the number on top (don't need them all). Could also cover them.

Anyway, some pictures. I'll do an upload of current state 3d files soon.

Case files: https://github.com/blueacro/reefvolt-essential-power-bar/tree/main/case

On an enhancement note, its probably pretty easy to add one of those small 1" OLED modules to the top case for displaying sensor values. The I2C bus is there, but I didn't give an easy header for 3.3V power or a secondary regulator. Can be tweaked.

Some other pending notes:

- I still want to experiment with the LEDs shining through the top of the case.

- The bottom of the case does not have holes for the Pi Zero ports to be accessible. It needs a variant to make that happen.

- I opted for holes to feed cables through to add some amount of moisture ingress protection. Maybe need to print some plugs for unused holes.

- Screws on top, are not unexpectedly, kinda ugly. I may reduce the number on top (don't need them all). Could also cover them.

Anyway, some pictures. I'll do an upload of current state 3d files soon.

Last edited:

Did a quick build of one relay channel just to check the part suitability. Of course, the first one I built, the diode ended up backwards, and then I melted the switch transistor by dumping an amp through the poor 2n4401.

Not used to needing a solder sucker gun because I don't do much through hole parts, but was easy enough to swap.

First off, the on LED is bright. I may reduce the current to it further.

The other good news is an average LED legs seem juuust long enough to go to the top case. While I don't want too many holes in the case, it would be nice if the on LEDs were visible. Need to think on this one (maybe some snap in thin white plastic over the LED? Translucent PETG?)

Tertiary note is the relay is loud - its chonky inside and isn't a soft click. Don't use this for a wavemaker and old school pumps.

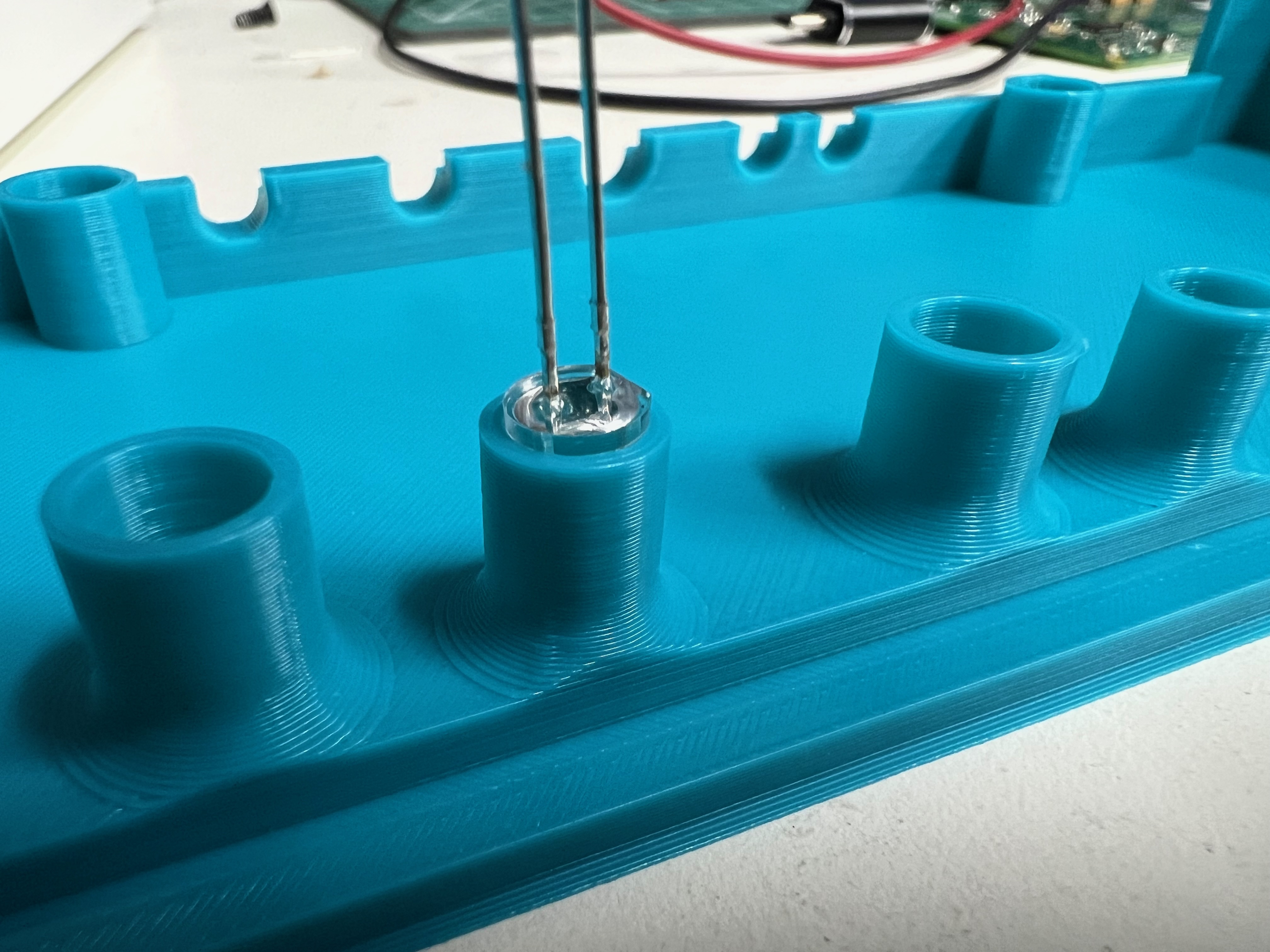

Follow up on the LED. I tested something which works way better than I was expecting it to...

Thats a multi-filament print using white, but thinned out so each LED area is simply about 2 layers of white PLA thick. Also gratuitous logo because why not

This is a backside view of it. The LED fits...

Just right. It does need some spacers to help set the LED height above the board, but thats a simple ring to print.

This looks great... if it had pH and Orb, it might be all I need for my IM 50 build... Any particular choice in mechanical vs SS for relays?

Really, simplicity. I also want to switch some large loads (big chiller) which start to put limits on the SSR.

My main uses are temperature, (heater + chiller), and one last remaining T5 ballast. The relays are audible, so its not something to switch all the time. They're big beefy relays for reliability in dealing with the chiller.

pH could be added on the expansion card with a ADS1015 + circuit and/or whatever isolator is required. For simplicity, I decided to leave it out. I don't have a good solution with the 3d print case to add connectors poking out without doing some sort of extra part to slide into a slot with holes on it. Might be worth exploring but don't want to over optimize on it.

I want to do a full build and do full-up circuit testing over the weekend. As it stands nothing on the PCB is a show stoper.

Last edited:

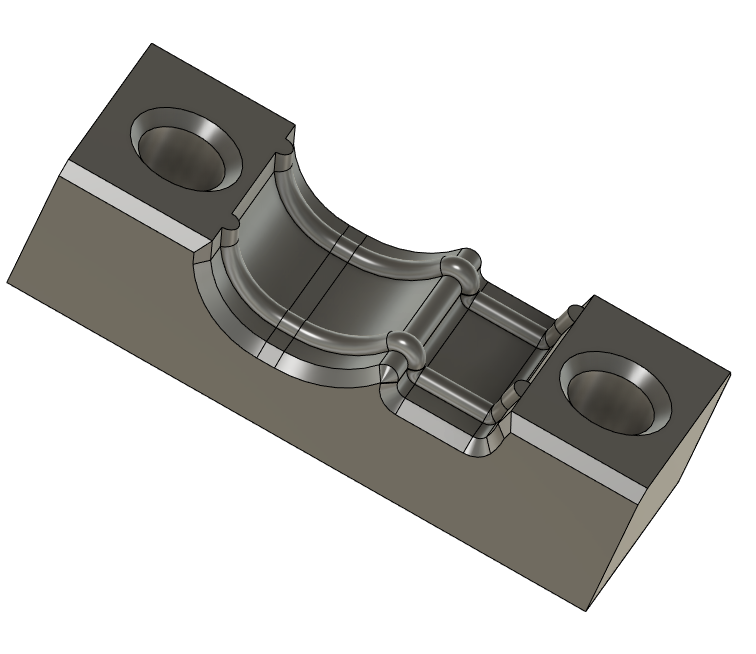

Looks awesome! I have been following your work for a while now on your blue acro site, very well thought out pcb designs and projects! Did you figure out your ac cable mount? If it helps, on my projects i have used a clamp style printed mount. Make a slightly oversize half circle base with threaded holes to either side for the mount, and another saddle clamp half circle that screws into the mount. Add 2 rows of raised hemispherical bosses circumscribing the inside of the mount and saddle that protrude ~.8mm to add a little grip and prevent cord pull out. Those style mounts have worked awesome for me in the past and are pretty secure. If you want i can screen-shot the cad drawing tomorrow if youd like.

Looks awesome! I have been following your work for a while now on your blue acro site, very well thought out pcb designs and projects! Did you figure out your ac cable mount? If it helps, on my projects i have used a clamp style printed mount. Make a slightly oversize half circle base with threaded holes to either side for the mount, and another saddle clamp half circle that screws into the mount. Add 2 rows of raised hemispherical bosses circumscribing the inside of the mount and saddle that protrude ~.8mm to add a little grip and prevent cord pull out. Those style mounts have worked awesome for me in the past and are pretty secure. If you want i can screen-shot the cad drawing tomorrow if youd like.

I hadn’t yet spent time there and actually didn’t even think of using a print in saddle clamp. Great idea - there is room to make one externally.

I had thought of using snap on cord grips which then slide into a slot in the case (something like a gromet you’d find for a metal case), but the variability of power cords makes that a tough option. Screw down saddle clamp is much for versatile.

Snap in grips would definitely work, i just get lazy sometimes and don't want to have to hunt one down lol. I had room in this case to make them all internal tooI hadn’t yet spent time there and actually didn’t even think of using a print in saddle clamp. Great idea - there is room to make one externally.

I had thought of using snap on cord grips which then slide into a slot in the case (something like a gromet you’d find for a metal case), but the variability of power cords makes that a tough option. Screw down saddle clamp is much for versatile.

Here is a few screen-shots of one of mine, this one is actually for 2 cords, one is a rectangular AC cord, like for a power supply, the other for a 3 wire round extension cord.

Snap in grips would definitely work, i just get lazy sometimes and don't want to have to hunt one down lol. I had room in this case to make them all internal too

Here is a few screen-shots of one of mine, this one is actually for 2 cords, one is a rectangular AC cord, like for a power supply, the other for a 3 wire round extension cord.

Very nice - I'll ruminate if I can get this _inside_ the case. I know I can easily by growing the case but didn't have the foresight to add it around the PCB features. Food for thought though

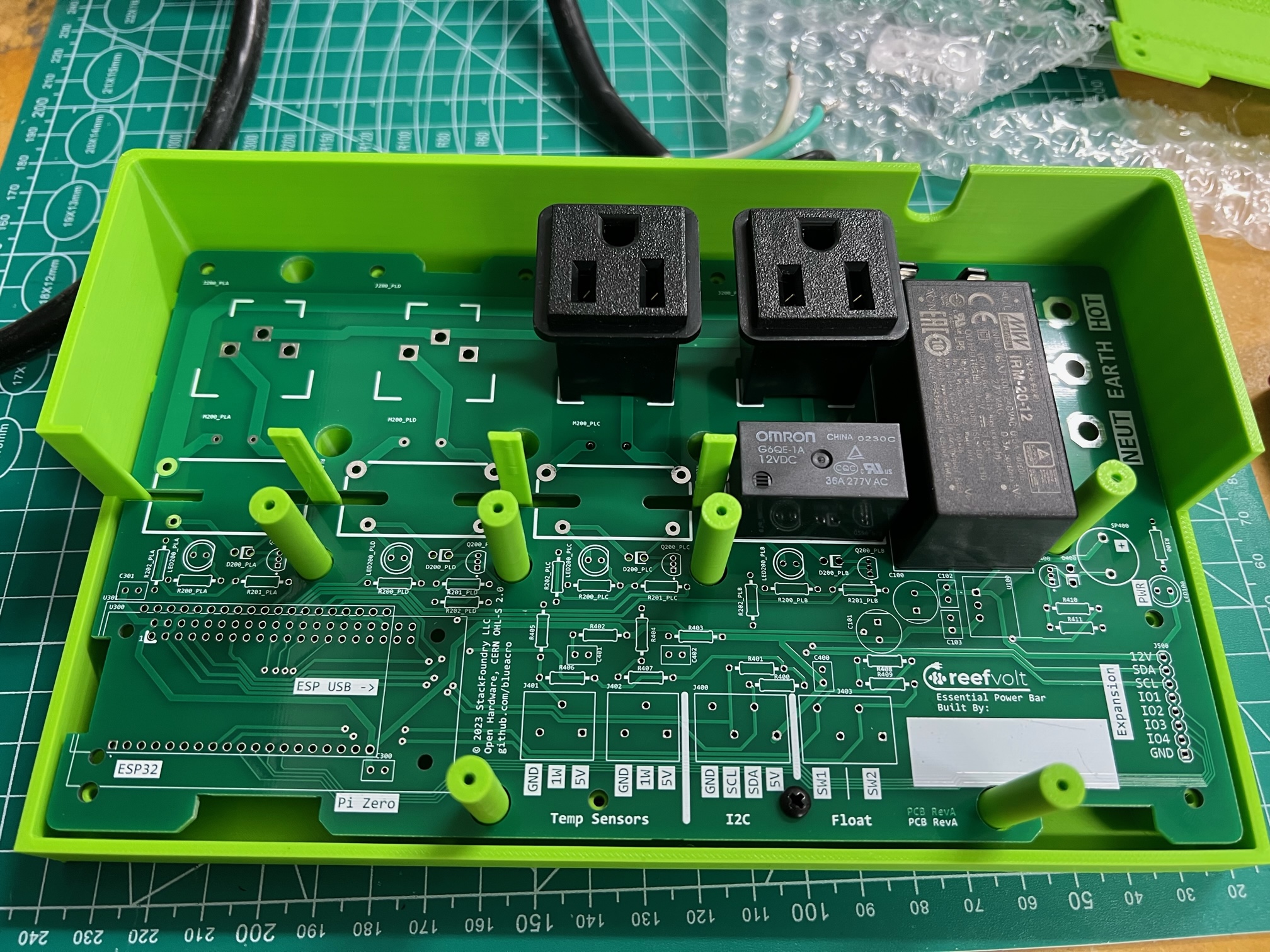

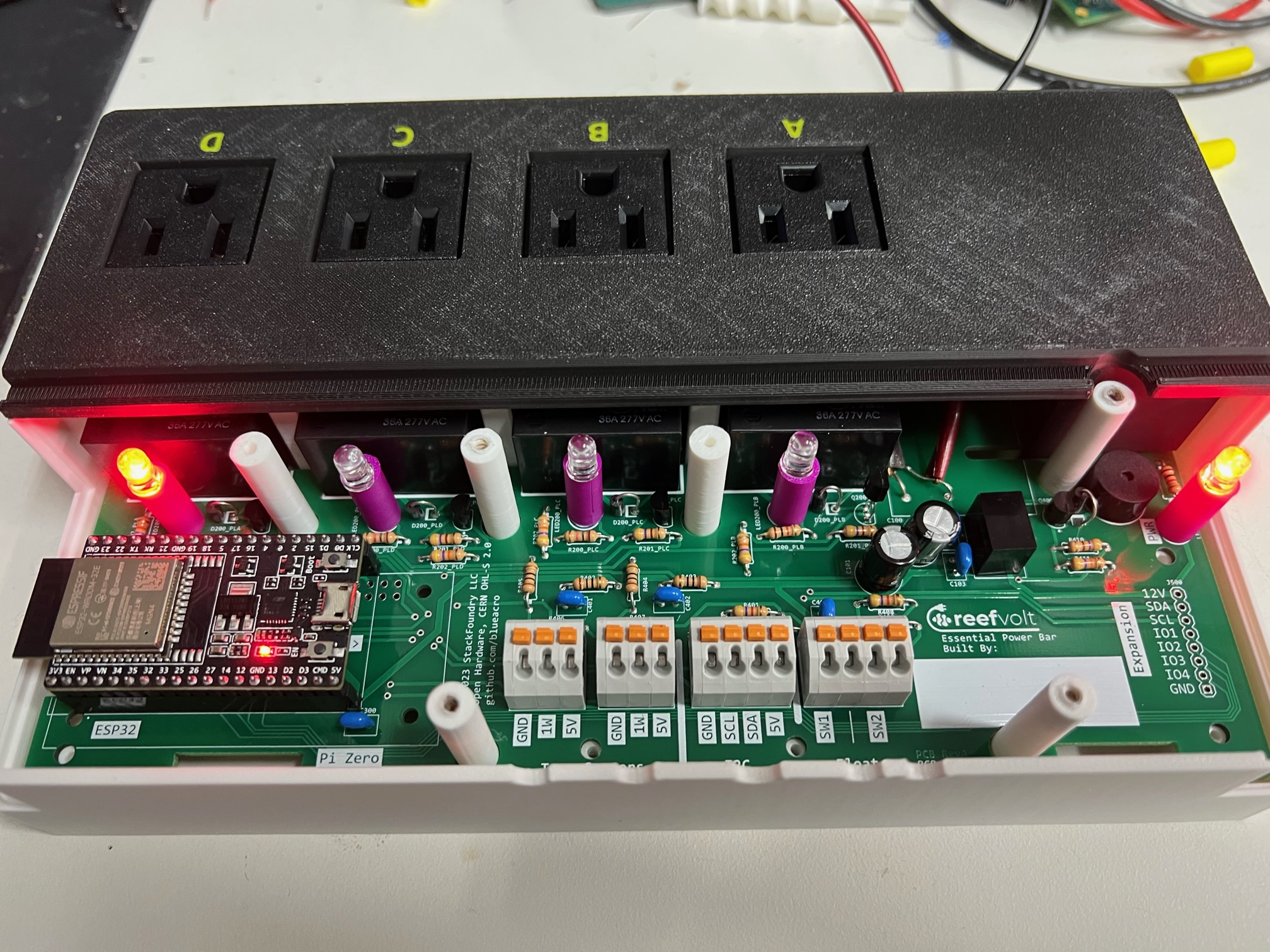

Some updates, built out the full PCB and performed a bunch of testing.

The good news its mostly functional, however I'm prepping a Revision B to clean up things:

- I was a muppet and used some of the ESP32 pins which are boot-strap pins for the 1wire and relay connectors. This means you can't program the ESP32 while its plugged into the socket. Will fix.

- The 5V supply works great (tested at bursts to 2A, no drop out), but if you power the ESP32 it leaks 5V right back to the 12V side. This is enough to light the LEDs, but won't actuate relays. Not sure if its worth fixing this, but its just a diode.

- I somehow ended up with non-plated holes for the buzzer. This meant soldering on the bottom didn't connect to the pads on the top, which leads to a non-working state. Will fix.

The biggest issue:

The G6QE relays are massive power hogs. Turns out, they're intended to be driven from a dual-voltage setup (full power for 100ms, then drop voltage to 35% to hold). This complicates firmware. Not doing this means each relay eats over 1W of power, which is too much for a closed case with no airflow (gets upwards of 80C case temperature on the relay just to be "on").

I'm swapping the relays to the G5RL-1A4-E-HR/TV8 series. Much lower power. Somewhat smaller. Quieter. 16A is more than enough, especially with the higher rated cycles. Only risk is large motor loads being less nice to the relay.

There is an added bonus in that the relay/outlet area is smaller, meaning more board space for other things (or shrinking it). I'm working on the case updates to get this in place, just dealing with the usual suspects of exploded CAD references all over the place .

The good news its mostly functional, however I'm prepping a Revision B to clean up things:

- I was a muppet and used some of the ESP32 pins which are boot-strap pins for the 1wire and relay connectors. This means you can't program the ESP32 while its plugged into the socket. Will fix.

- The 5V supply works great (tested at bursts to 2A, no drop out), but if you power the ESP32 it leaks 5V right back to the 12V side. This is enough to light the LEDs, but won't actuate relays. Not sure if its worth fixing this, but its just a diode.

- I somehow ended up with non-plated holes for the buzzer. This meant soldering on the bottom didn't connect to the pads on the top, which leads to a non-working state. Will fix.

The biggest issue:

The G6QE relays are massive power hogs. Turns out, they're intended to be driven from a dual-voltage setup (full power for 100ms, then drop voltage to 35% to hold). This complicates firmware. Not doing this means each relay eats over 1W of power, which is too much for a closed case with no airflow (gets upwards of 80C case temperature on the relay just to be "on").

I'm swapping the relays to the G5RL-1A4-E-HR/TV8 series. Much lower power. Somewhat smaller. Quieter. 16A is more than enough, especially with the higher rated cycles. Only risk is large motor loads being less nice to the relay.

There is an added bonus in that the relay/outlet area is smaller, meaning more board space for other things (or shrinking it). I'm working on the case updates to get this in place, just dealing with the usual suspects of exploded CAD references all over the place .

Similar threads

- Replies

- 17

- Views

- 499

- Replies

- 31

- Views

- 601

New Posts

-

-

-

-

-

Large (for me) tank build - Need some help with flow

- Latest: WhatCouldGoWrong71