They’re sicce pumps.Is that CPR hosing you have going to your sump? Is that a CPR sump? I'm just curious if that tubing can glue into regular pvc fittings.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Going all in.

- Thread starter SeaJay

- Start date

- Tagged users None

Thank you.Welcome to R2R. That's a nice tank!

I see it also comes in clear. That'll be pretty cool.Hard piping is best bet and eady ti glue and route. Easy to cut fir duassemby and you can add shutoffs in the routing. They now come in colors also

I see it also comes in clear. That'll be pretty cool.

Be aware if you get clear that any light source near the clear plumbing will allow algae to grow on the insides and turn them a nasty color/dirty looking.

Good luck! Coming along well!

I'm going to hard plumb everything tonight. Do you put gate valves in the returns and the pump lines, or just the returns? I don't really see where there would ever be need to cut the flow from the pumps when you can just turn them off, unless there's some kind of need to prevent backflow.Welcome! I have the same Eshopp. I did find out that those hoses where a little noisier. I did hard pluming with a gate valve to make it quite. Just a thought.

Also, I would make that wall outlet a GFI in case water get into it.

Also, when the system is turned off and the overflows are full, is it normal for the water to leak down into the sump? The overflow drain tubes are slip fit in side the bulkhead fittings. Should this be glued? Is it maybe the joint in the adjustable tube?

I'm going to hard plumb everything tonight. Do you put gate valves in the returns and the pump lines, or just the returns? I don't really see where there would ever be need to cut the flow from the pumps when you can just turn them off, unless there's some kind of need to prevent backflow.

Also, when the system is turned off and the overflows are full, is it normal for the water to leak down into the sump? The overflow drain tubes are slip fit in side the bulkhead fittings. Should this be glued? Is it maybe the joint in the adjustable tube?

https://www.reef2reef.com/threads/overflow.356819/page-3

Read that and my thread page. It will give you an idea. @Crabs Mcjones Crabs explained it to me the most and help a ton!

SeaJay.

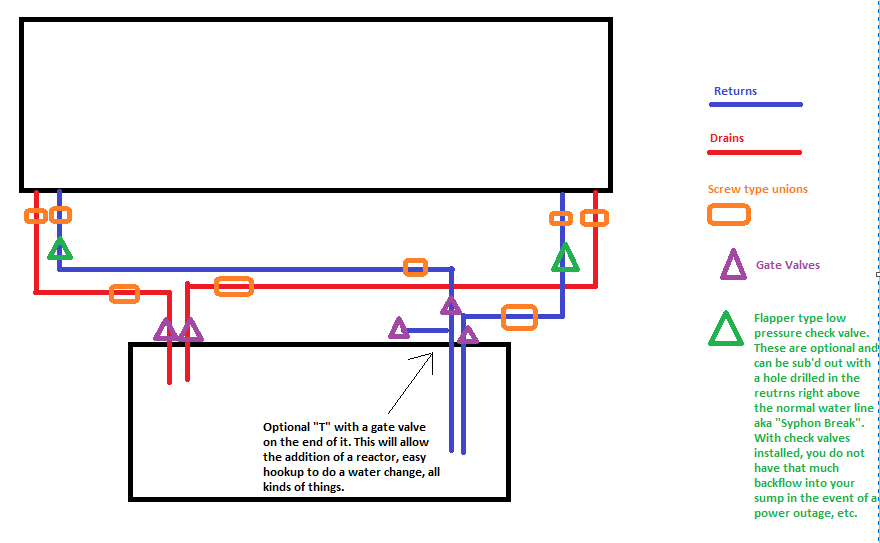

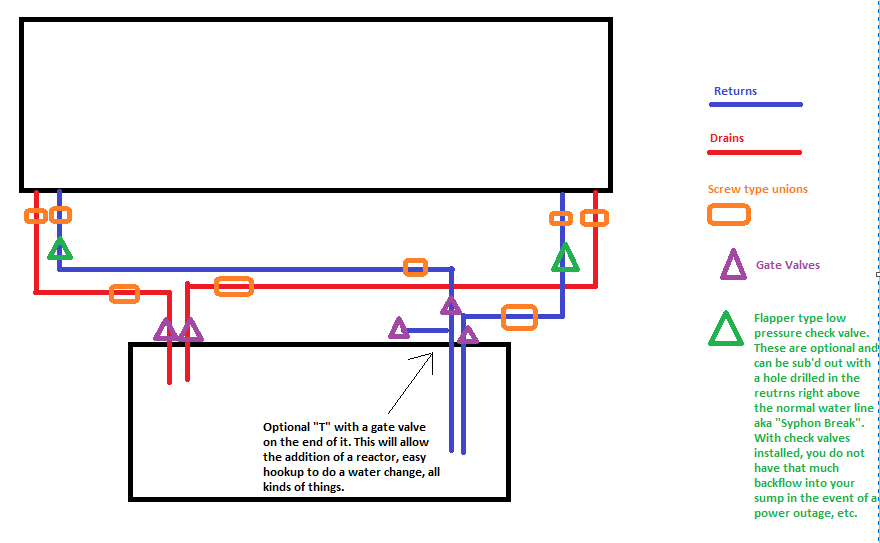

There are a ton of options when it comes to plumbing and you will get a few different answers on how to do things. My preference is to use as many unions as possible for quick and easy disassembly if needed and to always think ahead. Due to having numerous unions installed, I have been able to take out a section of pipe and add things in. I needed more flow in my fuge for example. I took out a section of return, cut it, added a "T" and a gate valve, routed from the gate valve back to my fuge, set gate valve for the flow I wanted and done. Easy due to having unions.

1. I prefer gate valves in all of the hard plumbing. Return and Drains. This will allow you to balance flow on either side if wanted, and can be used as a way to prevent drain back in the event a pump needs to be replaced.

2. I also prefer the low pressure swing arm check valves. I used to run my returns with a small hole drilled in them just above the water line to eliminate the drain back siphon, but they made a hair of noise my wife didn't like. Now with them, if you had a snail or something get in them (has to make it through the pump to do that), they can stop working. They will need to be cleaned every so often, but get the ones with unions or they even have them with a clean out port made into them. Again this is personal preference, but mine have worked flawlessly for over a year.

3. When you refer to the drain tunes being slip fittings, is this where the drains go into the sump, bottom of the bulkhead outside of the tank, or the tubes inside of the overflow box? Referring to entering the sump - No glue. Referring to the bottom of the bulk head coming out of the tank - it should have a threaded inside. Install a threaded to slip adapter, then use a union right after it. Or use a threaded on one end union and just use a dual threaded connector. For inside the tank portion of the bulkhead - if it is slip that is fine leave as it.

4. Below i have a crude diagram of how a lot of tanks I know of are setup. This also has an options gate valve installed in the return for use of a reactor or something else later. I use mine for a dual reactor. It has even been used for small water changes as My sump is huge and so is my pump chamber. Again, I am not an artist or creative outside of making things with 4 wheels go fast or figuring out how a network is jacked. So please excuse my crayola artwork lol.

Also if you have anymore questions just post them here. There are a ton of people with loads of knowledge on here and between everyone here, we should be able to aid you in coming up with the best solution to fit your needs.

There are a ton of options when it comes to plumbing and you will get a few different answers on how to do things. My preference is to use as many unions as possible for quick and easy disassembly if needed and to always think ahead. Due to having numerous unions installed, I have been able to take out a section of pipe and add things in. I needed more flow in my fuge for example. I took out a section of return, cut it, added a "T" and a gate valve, routed from the gate valve back to my fuge, set gate valve for the flow I wanted and done. Easy due to having unions.

1. I prefer gate valves in all of the hard plumbing. Return and Drains. This will allow you to balance flow on either side if wanted, and can be used as a way to prevent drain back in the event a pump needs to be replaced.

2. I also prefer the low pressure swing arm check valves. I used to run my returns with a small hole drilled in them just above the water line to eliminate the drain back siphon, but they made a hair of noise my wife didn't like. Now with them, if you had a snail or something get in them (has to make it through the pump to do that), they can stop working. They will need to be cleaned every so often, but get the ones with unions or they even have them with a clean out port made into them. Again this is personal preference, but mine have worked flawlessly for over a year.

3. When you refer to the drain tunes being slip fittings, is this where the drains go into the sump, bottom of the bulkhead outside of the tank, or the tubes inside of the overflow box? Referring to entering the sump - No glue. Referring to the bottom of the bulk head coming out of the tank - it should have a threaded inside. Install a threaded to slip adapter, then use a union right after it. Or use a threaded on one end union and just use a dual threaded connector. For inside the tank portion of the bulkhead - if it is slip that is fine leave as it.

4. Below i have a crude diagram of how a lot of tanks I know of are setup. This also has an options gate valve installed in the return for use of a reactor or something else later. I use mine for a dual reactor. It has even been used for small water changes as My sump is huge and so is my pump chamber. Again, I am not an artist or creative outside of making things with 4 wheels go fast or figuring out how a network is jacked. So please excuse my crayola artwork lol.

Also if you have anymore questions just post them here. There are a ton of people with loads of knowledge on here and between everyone here, we should be able to aid you in coming up with the best solution to fit your needs.

Thanks for the input.SeaJay.

There are a ton of options when it comes to plumbing and you will get a few different answers on how to do things. My preference is to use as many unions as possible for quick and easy disassembly if needed and to always think ahead. Due to having numerous unions installed, I have been able to take out a section of pipe and add things in. I needed more flow in my fuge for example. I took out a section of return, cut it, added a "T" and a gate valve, routed from the gate valve back to my fuge, set gate valve for the flow I wanted and done. Easy due to having unions.

1. I prefer gate valves in all of the hard plumbing. Return and Drains. This will allow you to balance flow on either side if wanted, and can be used as a way to prevent drain back in the event a pump needs to be replaced.

2. I also prefer the low pressure swing arm check valves. I used to run my returns with a small hole drilled in them just above the water line to eliminate the drain back siphon, but they made a hair of noise my wife didn't like. Now with them, if you had a snail or something get in them (has to make it through the pump to do that), they can stop working. They will need to be cleaned every so often, but get the ones with unions or they even have them with a clean out port made into them. Again this is personal preference, but mine have worked flawlessly for over a year.

3. When you refer to the drain tunes being slip fittings, is this where the drains go into the sump, bottom of the bulkhead outside of the tank, or the tubes inside of the overflow box? Referring to entering the sump - No glue. Referring to the bottom of the bulk head coming out of the tank - it should have a threaded inside. Install a threaded to slip adapter, then use a union right after it. Or use a threaded on one end union and just use a dual threaded connector. For inside the tank portion of the bulkhead - if it is slip that is fine leave as it.

4. Below i have a crude diagram of how a lot of tanks I know of are setup. This also has an options gate valve installed in the return for use of a reactor or something else later. I use mine for a dual reactor. It has even been used for small water changes as My sump is huge and so is my pump chamber. Again, I am not an artist or creative outside of making things with 4 wheels go fast or figuring out how a network is jacked. So please excuse my crayola artwork lol.

Also if you have anymore questions just post them here. There are a ton of people with loads of knowledge on here and between everyone here, we should be able to aid you in coming up with the best solution to fit your needs.

On #3, yes I was referring to inside the overflows where the drain tubes are just pushed down into the bulkhead.

So I’m assuming the black bulkheads are abs and we’re plumbing pvc, so what is the preferred method to join the two? It’s my understanding that you don’t want to use regular pvc glue for that.

Thanks for the input.

On #3, yes I was referring to inside the overflows where the drain tubes are just pushed down into the bulkhead.

So I’m assuming the black bulkheads are abs and we’re plumbing pvc, so what is the preferred method to join the two? It’s my understanding that you don’t want to use regular pvc glue for that.

For inside the overflows, leave as is. Makes maintenance and getting a fish out out of their easier.

For underneath the tank where your pipe to the sump will go, if it is threaded I would use a pvc connector that is threaded to slip and install it threaded in into the bulkhead. Be sure to use teflon tape and DO NOT OVER TIGHTEN. Bulkheads will crack easily. Form there put a short piece of PVC into the slip end and then into your union/coupler. From there the rest can be glued.

The fitting I am referring to is below and so are the unions.

Just make sure the threads match the threads on your bulkhead. Most are either 1" or 3/4". Should be a 1" on a dual overflow as large as yours, but do double check.

If the bulkheads are slip on the bottom side, then I have no idea how to properly join those together. Outside of matching the thread on the outside of the bulkhead and reducing it.

I feel like everything is running smoothly. Just been figuring things out. Realized that several extra filter socks are a must, so I got those. Also realized I’m gonna be spending a significant amount of time under the tank and the cell phone flashlight isn’t cutting it, so I added some lights under there so I can see what I’m doing. I got the water levels and everything dialed in, but I do have one small issue that’s causing me a little confusion. One of my overflows is fluctuating. It rises and falls about an inch or so every 5-10 seconds and spits a very small burst of bubbles into my display. I’m sure I could tinker with the levels and get it to stop, but I’d prefer to know exactly what’s going on so I can learn as much as possible.

Similar threads

- Replies

- 6

- Views

- 227

- Replies

- 22

- Views

- 680

- Replies

- 2

- Views

- 95

- Replies

- 20

- Views

- 337