I have had a very frustrating time with my bean animal overflow lately and I think I narrowed it down to my gyre because it the problems always seem to happen around the same time every morning, around the time the gyre shifts patterns and kicks up a few notches. The primary drain starts sucking air and making a ton of noise and the secondary drain ain't no quiet trickle. Sometimes it sets off my ATO alarm. Sometimes it happens when I change my filter socks, or when I pop the exterior box primary drain strainer out for a cleaning, too. Usually I go over and fiddle with the gate valve on the primary drain for a while, getting more and more frustrated that I can't keep this idiot-proof drain system working consistently. Today, I moved the gyre further down on my glass. It's going to move my sand all over the place, but there's less trouble with the drains. Still some air sucking, but not as bad. Is there a more permanent fix to this? If I keep the gyre as low as it is, I'll have bare spots and mountains in my sandbed, if I move it back up I get noisy and majorly nerve-wracking air suckage (it makes me panic every time, thinking there's something seriously wrong), and if I turn the power of the gyre down the hammer coral on the far end of the tank barely moves at all. I'm a night shifter who sleeps during the day, and when the drains start sucking air, it wakes me up in a panic. Guys....I am so tired.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gyre messing with my bean animal?

- Thread starter SallyWho

- Start date

- Tagged users None

An example. Yes, all that noise is the drains. In the evenings, it's quiet. You may have to turn the volume up a bit to hear- and if you listen carefully you can hear the quiet whine of the gyre ramping down near the end, followed by the drain noise tapering off a little.

Couple questions - How big is the tank? what return pump? what size are the drains? are there ANY horizontal runs in your drains? Is your return pump for absolute sure not fluctuating?

(video doesn't show up - try uploading it to youtube and then embedding it if you can)

FYI - i have multiple gyres doing some crazy flows in a 120 gallon tank and they have zero bearing on my drains - I have yet to see a powerhead alter the flow through drains.

(video doesn't show up - try uploading it to youtube and then embedding it if you can)

FYI - i have multiple gyres doing some crazy flows in a 120 gallon tank and they have zero bearing on my drains - I have yet to see a powerhead alter the flow through drains.

How many of inches of water are there between your primary and the durso? It sounds like they are too close together and you should cut some pipe on the primary or make the durso taller. If you have any guards I would try removing them to see if it improves things.

Couple questions - How big is the tank? what return pump? what size are the drains? are there ANY horizontal runs in your drains? Is your return pump for absolute sure not fluctuating?

How many of inches of water are there between your primary and the durso? It sounds like they are too close together and you should cut some pipe on the primary or make the durso taller. If you have any guards I would try removing them to see if it improves things.

The tank is 120g with 40b sump. Return pump is a Jebao DCT-8000, hooked up to my Apex via an Aqua A1Link module. Once I got that tuned in with Apex, the return has given me zero trouble. The tank's been up and running over a year, and this drain problem has only been the last few months. The drains are....1.25"? or so? I don't remember; I had to reduce them from big bulkheads. Pretty large for the tank size. I forgot to ask Modular Marine to customize the overflow box with slightly smaller bulkheads- I got a size up from recommended tank size because I wanted a bit more wiggle room in the exterior box. The only horizontal runs are angled downwards at least 30°, in the space from where the drain drops below the top edge of the stand into the sump. These have never given me trouble before.

There's not much room between the strainer of the primary drain and the durso of the secondary drain. There's just...not much room in there. But it was never an issue before, up until a few months ago. During maintenance, I've removed the strainer and durso for thorough scrubbings, used a toothbrush in the exterior box, and dumped tank water in there to rinse and flush down anything chunky into the filter sock before I put the durso pipe and strainer back in. They're firmly seated, but not so much that I can't pry them loose. The trick with the drains is that the manufactured bulkheads in the bottom are 1.5". So I need 1.5" pvc to fit in those holes for the durso pipes (2° drain and emergency drain). I was able to reduce them to 1.25" below the box, but there's a lot of thick pvc inside and I think raising the durso of the 2° drain will make it so I can't get it out- there's a cross brace on the box which makes getting that secondary durso irritating to remove already. If I try to put the e-drain in the middle, then there's no room for the U of the durso on the far side (not to mention, I'm an idiot and put all this together without realizing that I can't really reach the overflow box from the opposite side of the tank). The durso hangs right over the strainer as it sits now, and everything is a tight fit.

I'm just frustrated. I don't know what changed or what I messed up for a previously functioning overflow system to start malfunctioning. Oh, and today instead of fiddling with the gate valve, I just moved the gyre down and went to bed. When I got up, the drains were still making noise! I had really hoped the gyre was the cause, but if moving the gyre didn't work then I'm lost.

close the gate valve completely - make sure it's closed, let water run down the emergency for a minute or 2. Then open the gate valve ALL THE WAY as fast as you can.

It'll slurp and gurgle and be obnoxious - let it run that way for a minute or 2.

Then start slowly turning the gate valve - go slow in small increments. Keep closing it until the water level is at the right spot.

I'm not saying to do this because you don't know how to tune drain - I'm asking you to try to clear out anything in that drain.

Anytime I've had any oddness with my drains - this is what I have done and it always works. If it doesn't - you have something altering the flow of your return pump or there is algae blocking the weirs of the overflow.

OH - I have had a gate valve go bad as well - thats the other reason to completely close it and then open it. You're testing the health / functionality of the valve as well.

It'll slurp and gurgle and be obnoxious - let it run that way for a minute or 2.

Then start slowly turning the gate valve - go slow in small increments. Keep closing it until the water level is at the right spot.

I'm not saying to do this because you don't know how to tune drain - I'm asking you to try to clear out anything in that drain.

Anytime I've had any oddness with my drains - this is what I have done and it always works. If it doesn't - you have something altering the flow of your return pump or there is algae blocking the weirs of the overflow.

OH - I have had a gate valve go bad as well - thats the other reason to completely close it and then open it. You're testing the health / functionality of the valve as well.

- Joined

- Sep 22, 2018

- Messages

- 776

- Reaction score

- 797

The problem that he's having is that the gyre pushes a lot of water into the wier causing random and uneven flow into the overflow.

I solved this problem on mine by puting the primary with 2 90degree pvc as low as possible (i'm talking almost touching the bottom of the overflow, turning the return pump a little higher and changing the gyre to ramp every 4 seconds.

Either way you do it, you need to slow down the drain or increase the amount of water going into the overflow.

I solved this problem on mine by puting the primary with 2 90degree pvc as low as possible (i'm talking almost touching the bottom of the overflow, turning the return pump a little higher and changing the gyre to ramp every 4 seconds.

Either way you do it, you need to slow down the drain or increase the amount of water going into the overflow.

Maybe? It's going to be hard to see anything- the top of the 2° drain durso takes up most of the visual field from above. And I cleaned the return pump about a month ago when it started clacking. I didn't have any kind of guard on the intake- there was a snail in there. I took the opportunity to give it a right good cleaning before putting it back together and zip tying some mesh over the intake to keep snails out.Can you get a video of what's going on in the external box itself? Also when was the last time you cleaned your return pump?

That's a solid idea. And I haven't cleaned my overflow weirs in a long time, too. I'll give it a try, but probably not today. Really rough night at work- some patients were trying to die all night, and my analyzers kept malfunctioning and....well, you get the idea. I'm the one drained today- not my tank! I'll deal with it tomorrow.close the gate valve completely - make sure it's closed, let water run down the emergency for a minute or 2. Then open the gate valve ALL THE WAY as fast as you can.

It'll slurp and gurgle and be obnoxious - let it run that way for a minute or 2.

Then start slowly turning the gate valve - go slow in small increments. Keep closing it until the water level is at the right spot.

I'm not saying to do this because you don't know how to tune drain - I'm asking you to try to clear out anything in that drain.

Anytime I've had any oddness with my drains - this is what I have done and it always works. If it doesn't - you have something altering the flow of your return pump or there is algae blocking the weirs of the overflow.

OH - I have had a gate valve go bad as well - thats the other reason to completely close it and then open it. You're testing the health / functionality of the valve as well.

The first thing you have to do is see whether the operation of the gyre pump is affecting the consistency of flow through the overflow. From the video, doesn’t seem like that’s the case. Second, do you run your bean with a dry secondary or with a trickle. Most, but not all, do the latter. I have a modular marine overflow and found a few tweaks that help.

A U tube or dual elbows serves no useful purpose on the primary siphon. I just use a strainer directly in to the bulkhead. Place your emergency as high as you can while still having adequate clearance should it be required to handle 100% flow. That allows you to have the secondary a bit higher and makes the overflow less vulnerable to occasional water volume changes. Start by closing down the primary a little more so you get extra flow through the secondary. See if that prevents a vortex through the primary. If it does, open up the primary a bit and see if it remains quiet .... and so on.

A U tube or dual elbows serves no useful purpose on the primary siphon. I just use a strainer directly in to the bulkhead. Place your emergency as high as you can while still having adequate clearance should it be required to handle 100% flow. That allows you to have the secondary a bit higher and makes the overflow less vulnerable to occasional water volume changes. Start by closing down the primary a little more so you get extra flow through the secondary. See if that prevents a vortex through the primary. If it does, open up the primary a bit and see if it remains quiet .... and so on.

Last edited:

The first thing you have to do is see whether the operation of the gyre pump is affecting the consistency of flow through the overflow. From the video, doesn’t seem like that’s the case. Second, do you run your bean with a dry secondary or with a trickle. Most, but not all, do the latter. I have a modular marine overflow and found a few tweaks that help.

A U tube or dual elbows serves no useful purpose on the primary siphon. I just use a strainer directly in to the bulkhead. Place your emergency as high as you can while still having adequate clearance should it be required to handle 100% flow. That allows you to have the secondary a bit higher and makes the overflow less vulnerable to occasional water volume changes. Start by closing down the primary a little more so you get extra flow through the secondary. See if that prevents a vortex through the primary. If it does, open up the primary a bit and see if it remains quiet .... and so on.

This is great advice. A lack of vertical separation between the primary and secondary could be what's making it so hard to tune. This would cause every little variation in flow coming through the weir to throw it out of balance, like you seem to be experiencing.

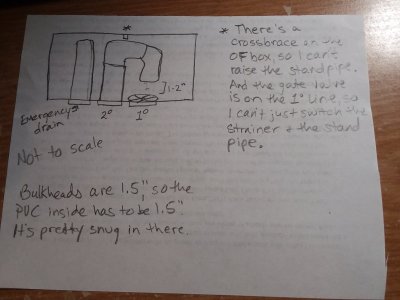

Probably impossible to take a photo of the drain setup inside your box without disassembly, but could you make a little drawing of what you have going on in there? Might help people understand.

Yeah, so that's tricky. I bought the 1800gph Modular Marine overflow and I really do love it (my problems are likely user-error). But I forget to ask them to size down the drain bulkheads, so the bulkheads are 1.5". I was able to reduce to 1.25" inches below the box, but the standpipes on the inside of the box still need to be 1.5" PVC, which makes everything in there super tight. My primary drain is just a strainer. The emergency drain is just a straight pipe. The secondary drain is set up as a U-shaped standpipe but because of it having to be 1.5" pvc, I have it as tall as it will go while still being able to get it out. If I try to raise it even by a quarter inch, I'll never be able to remove it. So it does lurch probably only an inch or two above the strainer. I'm not sure if there's a PVC fitting I could use to reduce the 1.5" pvc down while still maintaining the u-shape and not taking up any more room. And would having a secondary drain that has a smaller aperture leading into a bigger body before draining out of the box make things noisy?This is great advice. A lack of vertical separation between the primary and secondary could be what's making it so hard to tune. This would cause every little variation in flow coming through the weir to throw it out of balance, like you seem to be experiencing.

What I did with mine(not a modular marine, just a diy) was to make the secondary a 90 instead of a U which would give you another inch of separation. The secondary will make more noise without the U but not a lot of noise when it's dialed in.

Can you draw a picture? Of the inside setup and the outside all the way to the sump? Including the diameter of the fittings and reducers.

Can you guess the GPH of your return pump?

To isolate the issue, can you turn of the gyres right before the time this happens?

Is the noise coming from increased flow in the backup or a vortex in primary?

The setup might not be to "spec" for a beananimal but if it was working silently before, then the issue is either your gyres or return pump changing the amount of water flowing in to the overflow.

Can you guess the GPH of your return pump?

To isolate the issue, can you turn of the gyres right before the time this happens?

Is the noise coming from increased flow in the backup or a vortex in primary?

The setup might not be to "spec" for a beananimal but if it was working silently before, then the issue is either your gyres or return pump changing the amount of water flowing in to the overflow.

Pic included, but I'm no artist.Can you draw a picture? Of the inside setup and the outside all the way to the sump? Including the diameter of the fittings and reducers.

Can you guess the GPH of your return pump?

To isolate the issue, can you turn of the gyres right before the time this happens?

Is the noise coming from increased flow in the backup or a vortex in primary?

The setup might not be to "spec" for a beananimal but if it was working silently before, then the issue is either your gyres or return pump changing the amount of water flowing in to the overflow.

My return pump is a Jebao DCT-8000 with a Max flow: 2113GPH; Max-head: 14.8 ft. I use an Aqualink A1 module to control it with my Apex. It's currently at 60% I think? But it was finicky to set up, so there could conceivably be variations in flow coming from my return pump.

The noise can originate anywhere. Either the primary drain is sucking air in a loud vortex, gushing like a waterfall (if the gate valve is open too far, for example), or the secondary drain gets loud. I'll adjust it for quieter flow on Monday, and by Thursday I have to adjust it again. Usually I have to close the gate valve a smidge. I'll creep it more and more closed each time the primary drain starts making those popping and sucking noises, until one day the secondary drain starts whooshing and I have to open the gate valve back up and retune it. I made a mark on the gate valve so I can keep track of how far I'm turning it.

You probably have a hole in the top of that U

I think

The main drain is sucking air down from it and becoming noisy before you get the flow through it high enough.

I would remove all that stuff and put a second standpipe 1/2 inch shorter than the other one in and then try to tune it so only a trickle goes down it.

I think

The main drain is sucking air down from it and becoming noisy before you get the flow through it high enough.

I would remove all that stuff and put a second standpipe 1/2 inch shorter than the other one in and then try to tune it so only a trickle goes down it.

There is a hole drilled into the top of that 90 on the secondary drain. I thought it needed a hole as a siphon break, just in case? And I know the drawing looks like there's room, but there is absolutely no way to put anything other than a strainer on the primary drain. Unless you mean to remove the u-bend part and have my 2° drain be just a straight piece of pvc? I thought I needed a standpipe style 2° to keep it quiet?You probably have a hole in the top of that U

I think

The main drain is sucking air down from it and becoming noisy before you get the flow through it high enough.

I would remove all that stuff and put a second standpipe 1/2 inch shorter than the other one in and then try to tune it so only a trickle goes down it.

Similar threads

- Replies

- 6

- Views

- 144

- Replies

- 8

- Views

- 235

- Replies

- 6

- Views

- 352