Thanks for all the quick feedback everyone! all suggestions welcomed..

Unfortunately this is just too high for my blood pressure and absolutely not approved by my partner She couldn't believe some of you said to keep it this high

She couldn't believe some of you said to keep it this high

Screw up as in 'well have to order a new one now cause it's in pieces'.. or 'it's ugly but works'

Unfortunately this is just too high for my blood pressure and absolutely not approved by my partner

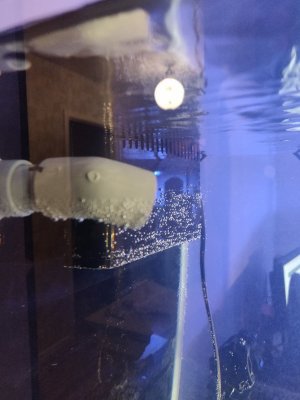

Yes. I have successfully dremeled teeth in acrylic but it's tough to not screw up.

Screw up as in 'well have to order a new one now cause it's in pieces'.. or 'it's ugly but works'