- Joined

- Feb 15, 2017

- Messages

- 139

- Reaction score

- 149

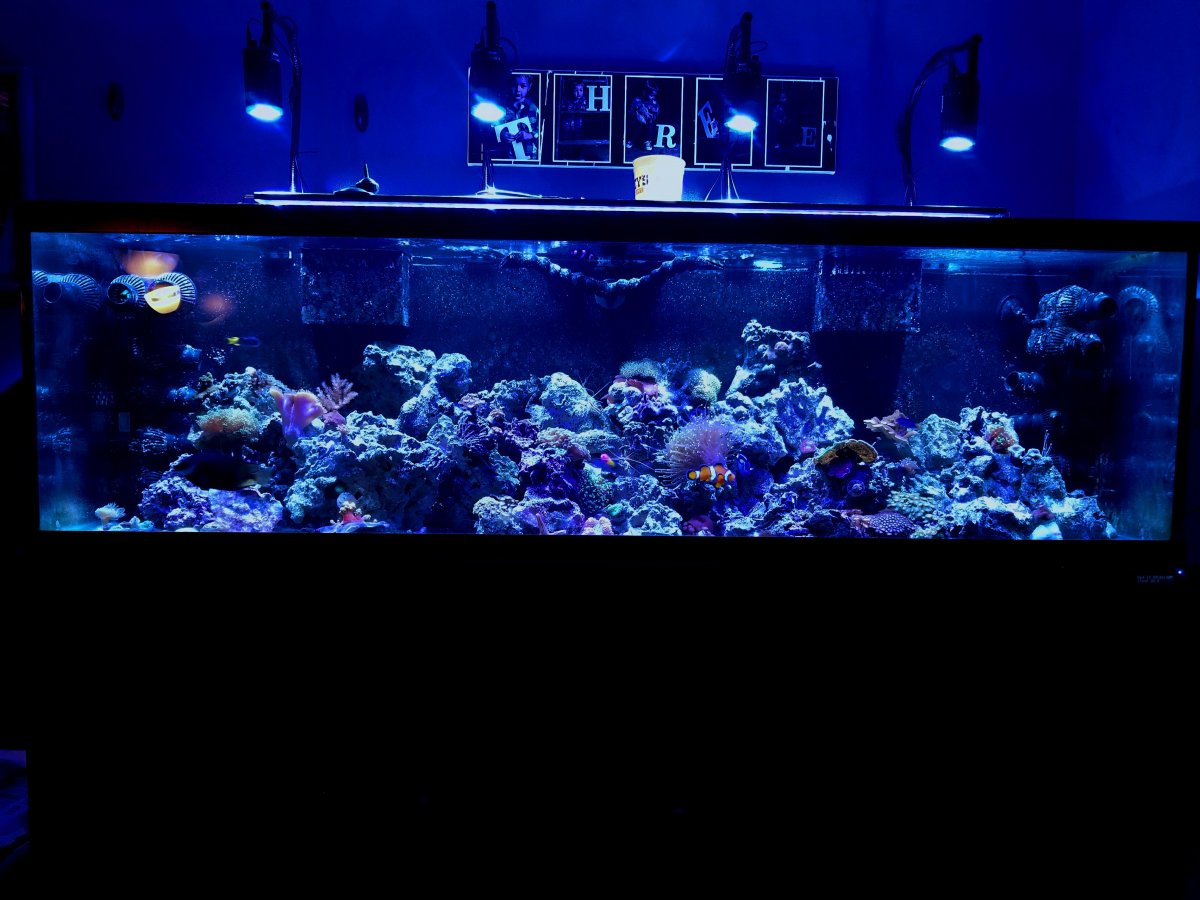

So it finally happened--that moment when you know you let your tank go way too far down the wrong road. I have previously built a 125 gallon tank and created a sump out of a 55 gallon tank. I drilled the 125 myself and did all schedule 80 plumbing with red schedule 40 PVC pipe. I loved the way it looked and over the course of about 1.5 years, it was looking great. But then life got in the way. In becoming incredibly busy and creating a tank at my office, I let my 125 go. Everything maintained itself for awhile, but when the remainder of my dosing solution ran dry, I started loosing some of my stony corals.

I had decided that it was time to go down to 1 tank. I had my 125 at home and my Nuvo 40 at my office. All of my nice equipment was on the Nuvo 40 so I decided to keep that. I removed the rock from my 125, drained the water, and quarantined the fish. And then it hit me--I can't get rid of this tank. No matter how bad I want to go down to one tank, I have had an aquarium up and running at home for so long, I couldn't get rid of this thing. So I did what most reasonable reefers would do--I am keeping the tank at home--sort of.

I decided it was time to completely rebuild my tank. Pretty much the only thing I'll be using from my old tank is the Vertex Omeaga 150 skimmer and the stand I built. I also decided it was time to part ways with my office tank. It is difficult to keep up with maintenance on an office tank when you have a family to get home to and have to haul water down the road. Here is to a happy year reefing!

I had decided that it was time to go down to 1 tank. I had my 125 at home and my Nuvo 40 at my office. All of my nice equipment was on the Nuvo 40 so I decided to keep that. I removed the rock from my 125, drained the water, and quarantined the fish. And then it hit me--I can't get rid of this tank. No matter how bad I want to go down to one tank, I have had an aquarium up and running at home for so long, I couldn't get rid of this thing. So I did what most reasonable reefers would do--I am keeping the tank at home--sort of.

I decided it was time to completely rebuild my tank. Pretty much the only thing I'll be using from my old tank is the Vertex Omeaga 150 skimmer and the stand I built. I also decided it was time to part ways with my office tank. It is difficult to keep up with maintenance on an office tank when you have a family to get home to and have to haul water down the road. Here is to a happy year reefing!