So for piping a return line I’m curious if anyone can give a cursory explanation or math behind the restriction piping size can put on a pumps gph rating. I’ve been running a Neptune cor-15 on a Waterbox 130.4. At the end of the run, the flow goes through a metric 3/4” equivalent (DN25 if I’m not mistaken) to a tee and then loc line to the display. I was getting just over running from a 1-1/4” union to a 1” bushing, some 1” pipe, flow meter, and elbows, a 3/4” reducer, check valve and out. I decided I wanted to a) increase overall turn over and b) run equipment off the return pump (reactor, uv).

I reran the plumbing in 3/4” and got a similar flow rate. Basically starting with 1-1/4” and using 1” for most of the run didn’t really matter.

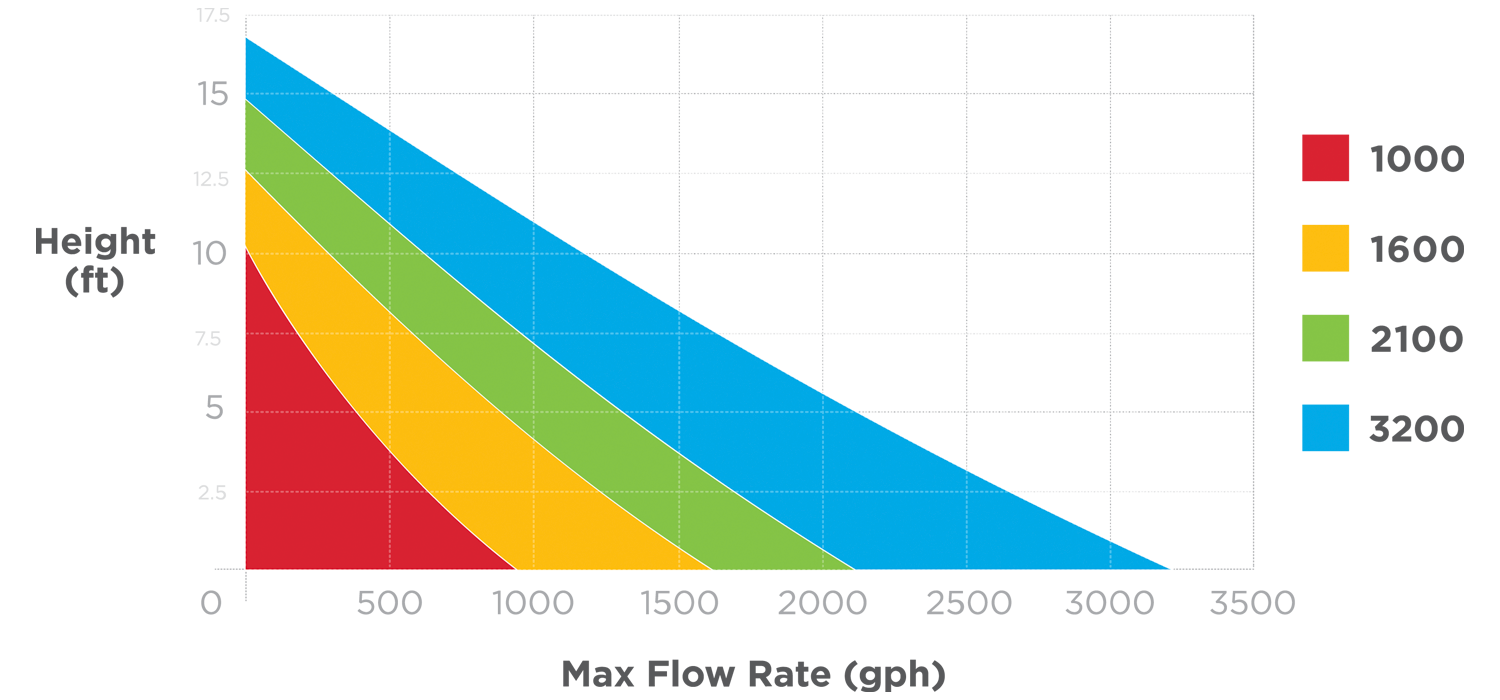

So now I’m trying to size a pump and curious how big I can go before the 3/4” restriction just gives diminishing returns. Can I put a varios-8 or a ETM L2 on this and get 7-800+ with a few hundred for accessories? I want about 300gph for my uv and another 1-200 for the reactor.

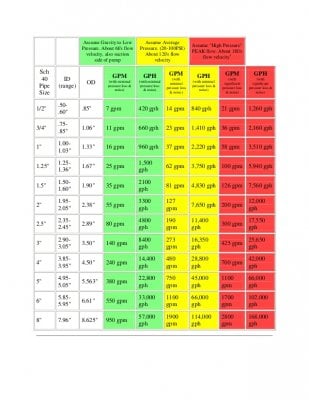

Basically, what’s a good strategy to try and calculate flow (via head pressure?) with a more complex setup than just straight gravity flow and 90s? If you have 3/4” return, 3/4” uv, 1/2” reactor does that help with the restriction that the 3/4” pipe puts on the rated flow?

Or another way of looking at it, does putting a successively bigger pump on the same size line eventually stop yielding higher flow? Or just inefficient? Is there a max flow for 3/4” pipe?

I reran the plumbing in 3/4” and got a similar flow rate. Basically starting with 1-1/4” and using 1” for most of the run didn’t really matter.

So now I’m trying to size a pump and curious how big I can go before the 3/4” restriction just gives diminishing returns. Can I put a varios-8 or a ETM L2 on this and get 7-800+ with a few hundred for accessories? I want about 300gph for my uv and another 1-200 for the reactor.

Basically, what’s a good strategy to try and calculate flow (via head pressure?) with a more complex setup than just straight gravity flow and 90s? If you have 3/4” return, 3/4” uv, 1/2” reactor does that help with the restriction that the 3/4” pipe puts on the rated flow?

Or another way of looking at it, does putting a successively bigger pump on the same size line eventually stop yielding higher flow? Or just inefficient? Is there a max flow for 3/4” pipe?