I'm tired of moving hoses and unplugging hose, using wetvac to initiate suction, etc. Not to mention the water that no matter how careful I am, gets a bit here or there (thank God I've got tile floors).

I've sketched out what I think will work, and would love to get some review and comments. My tank is a 210, and my idea is to have just a single hose that can be dropped in tank when ready to do a change.

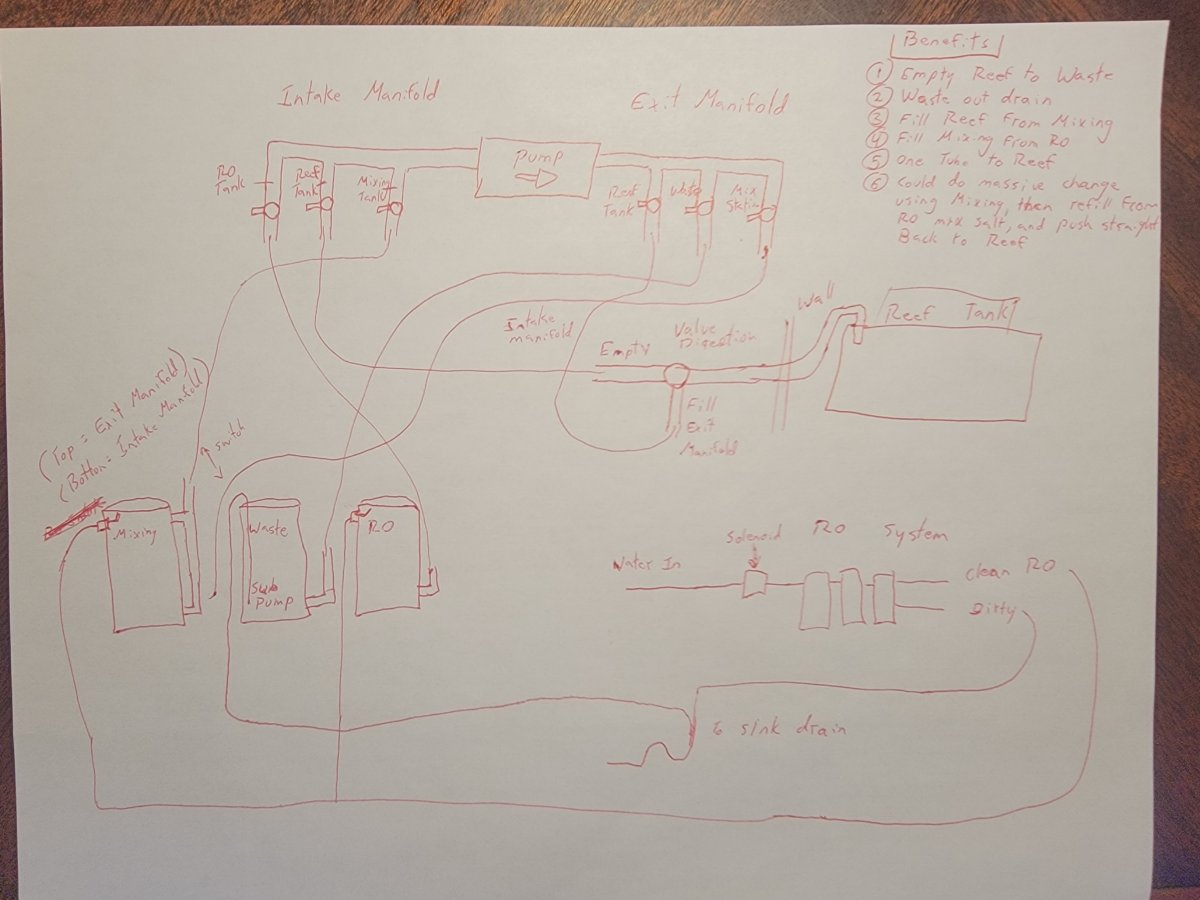

I've designed an intake manifold, and outtake manifold with an inline pump in between.

I have 3 @ 50 gallon containers. One is currently used for RO storage, another for Saltwater mixed, and the 3rd isn't used (a green garbage can that I was afraid could leech something, so I switched the mixing to a Brute.

The "fish room" is in a closet/stairwell 10 ft from tank.

I THINK with this layout, I can quickly empty from Reef tank to Waste Container (3rd 50 gallon container).

Then switch valves and just as quickly fill with fresh mix.

The waste container can then be emptied at a slower rate using the RO drain line.

The RO system should then be able to fill the Mixing station water, as well as top off the RO storage as well (I have an Apex solenoid that I'll only turn on if RO was extemely low, but reality is it will really only need to be turned on when doing a water change weekly or every other week).

I've also included valves for allowing the existing RO to flush to the Mixing in case I want to do an extra large water change.

I've sketched out what I think will work, and would love to get some review and comments. My tank is a 210, and my idea is to have just a single hose that can be dropped in tank when ready to do a change.

I've designed an intake manifold, and outtake manifold with an inline pump in between.

I have 3 @ 50 gallon containers. One is currently used for RO storage, another for Saltwater mixed, and the 3rd isn't used (a green garbage can that I was afraid could leech something, so I switched the mixing to a Brute.

The "fish room" is in a closet/stairwell 10 ft from tank.

I THINK with this layout, I can quickly empty from Reef tank to Waste Container (3rd 50 gallon container).

Then switch valves and just as quickly fill with fresh mix.

The waste container can then be emptied at a slower rate using the RO drain line.

The RO system should then be able to fill the Mixing station water, as well as top off the RO storage as well (I have an Apex solenoid that I'll only turn on if RO was extemely low, but reality is it will really only need to be turned on when doing a water change weekly or every other week).

I've also included valves for allowing the existing RO to flush to the Mixing in case I want to do an extra large water change.