In the middle of my water station is my 150 gallon per day 7 stage RODI filter from BRS

This was a recent purchase for me and it replaced a cheap no name RO filter that I had added a two stage DI filter on after. I actually purchased the BRS RODI unit as a 5 stage RODI with a single DI canister as well as a three canister bracket and took the two DI canisters that I already had as well as the single canister that came with the new RODI unit and built my own 3 canister DI unit. I emailed BRS and asked if they could send me the sticker for their 3 canister DI filter and they were kind enough to do so

If you look closely you can see that one of the DI canisters actually has nothing in it right now. My intention is to switch to the single bed DI resin as the canister labels suggest, but I want to use up the mixed bed DI resin that I have first, so until that happens I’m just running two mixed bed DI canisters.

There is a DOS installed in the garage that controls the auto water change system

I elevated the DOS slightly because I recently installed an apex flood sensor right under it. This DOS is worked pretty hard. It changes about 3 gallons of water a day and moves the water through about 40 feet of tube to get it from the garage to the tank and then another 40 or 50 feet from the tank to the laundry room. It seems that the tube in the heads lasts about a year before they spring a leak and the head starts dripping whenever it runs. The first time it happened I wound up with a bit of a puddle on my garage floor because I didn’t catch it right away, but I figured it was just a fluke and changed the head and forgot about it. Then about a year later the new head sprang a leak and I got another puddle. This time after I replaced the head I put the flood sensor right under the DOS so the apex will catch it right away and shut off the AWC and send me an email to notify me. Hopefully no more puddles this time . Now that I’m thinking about it, it might make sense to put the DOS and the flood sensor in a little tray to further contain any drips. I think I’ll do that.

. Now that I’m thinking about it, it might make sense to put the DOS and the flood sensor in a little tray to further contain any drips. I think I’ll do that.

Just as a quick note, I don’t think that this is really an inherent problem with the DOS. I think it’s just because I’m seriously overworking this unit with the fact that it’s moving so much water every day and it’s moving it over such a long distance. I have another DOS that I use to dose two part at much lower quantities and over a much shorter distance. That one has been in service for close to three years on this tank and the one before it and it has never had a head start to leak.

Under the shelf (for lack of space anywhere else) I have installed five 120V solenoid valves that are controlled by an apex EB8.

These are the heart of what automates my RODI filter and my ATO system.

The single solenoid was recently added and that’s the one that controls the RO membrane auto flush. The flow restrictor on the waste line is bypassed through that solenoid valve. Normally the valve is closed, so the waste water is forced through the flow restrictor and the RO membranes make water as normal, but whenever the RODI unit is on the apex will open the solenoid for 18 seconds of every hour to allow waste water to exit unrestricted and flush the membranes, which is supposed to help increase the life of the membranes. (For what it’s worth, BRS sells a standalone automatic flush valve and it operates for 18 seconds each hour, so that’s where I got those numbers. I had no idea how long it should run, but I assume that the manufacturer of that unit did some research to determine that flush time)

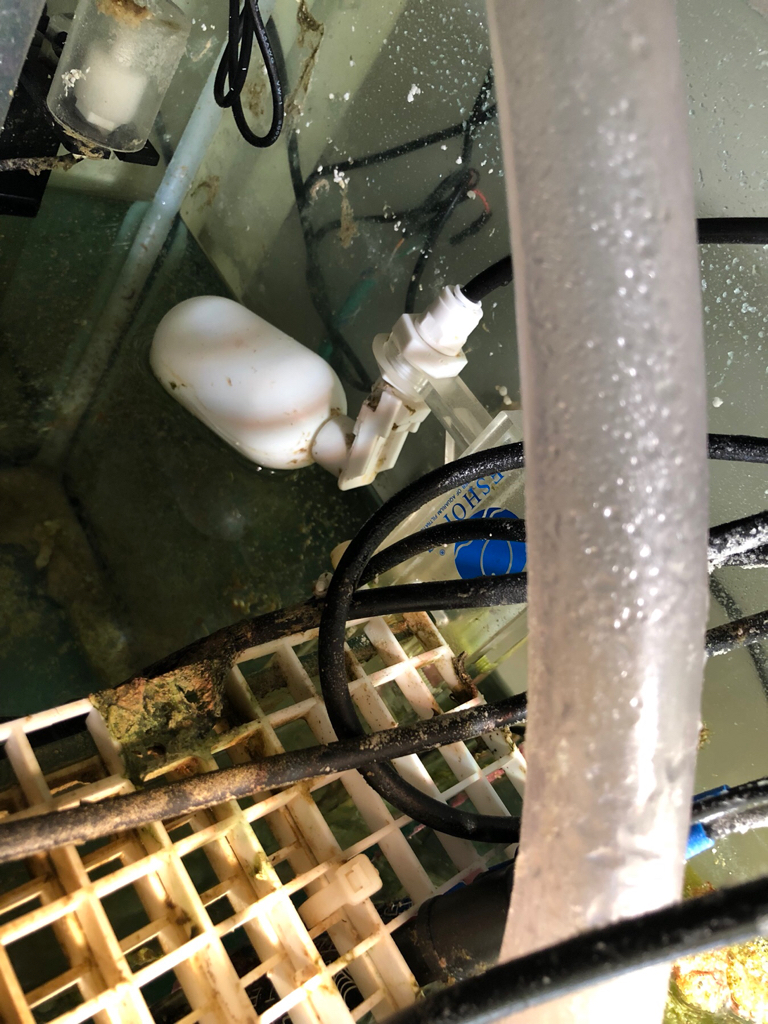

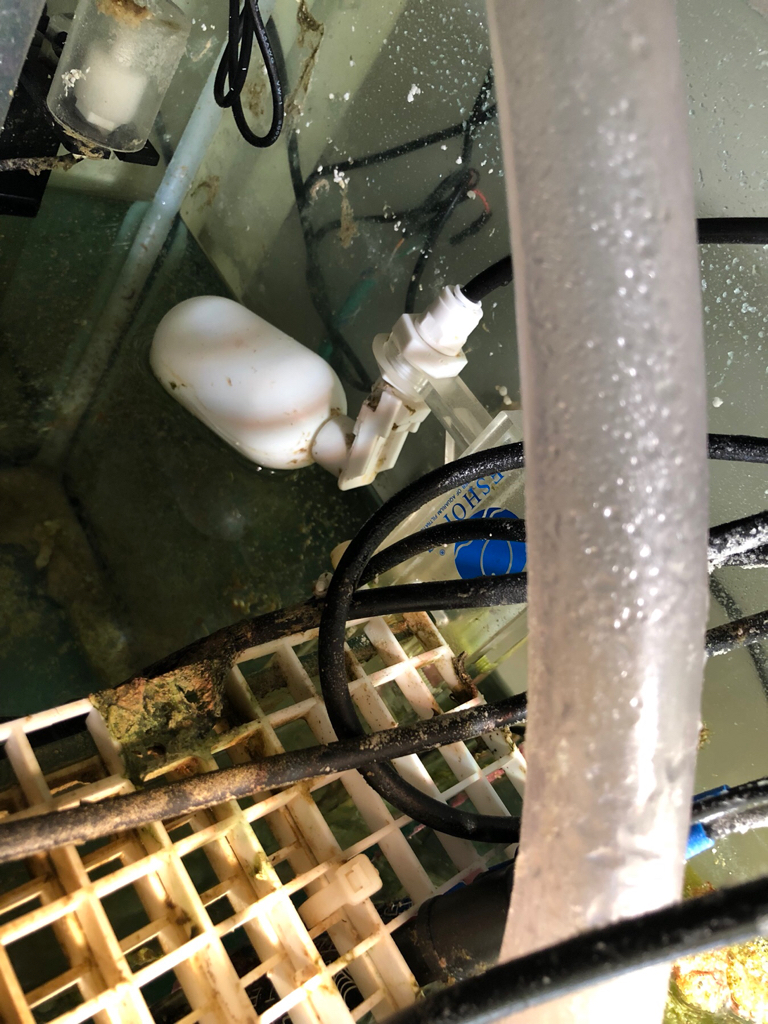

There is another solenoid that controls my auto top off. The auto top off is gravity fed from the reservoir on the shelf in the garage.

This reservoir holds about 20 gallons and is automatically refilled by the apex whenever it runs low. There is a siphon line in the reservoir that goes through the solenoid, then up into the attic and over to the tank, then through a float valve in the return pump section sump.

I have a few failsafes in place to help ensure that there are no floods from the automated system. The float valve is the first line of defense. When the water is at the correct level the float valve is closed and no water comes in. Additionally the apex only turns on the solenoid that runs the ATO for 2 minutes every 10 minutes. Because the system is gravity fed and it has to cover a long distance the water comes out at a very slow trickle. Running for 2 minutes every 10 minutes provides only slightly more water than is normally required to make up for evaporation. Even if the float valve were to fail, because the solenoid valve stays off most of the time the water level in the sump would only rise very slowly and it would be days before it could overflow. I also have two high level float switches in the sump that would alert me when the water level is starting to rise well before the sump would actually flood. One float switch is set at just slightly above the normal operating level and one is closer to the top of the sump and would indicate a more urgent situation. If either float switch is tripped the apex shuts off the ATO and notifies me of the problem.

This was a recent purchase for me and it replaced a cheap no name RO filter that I had added a two stage DI filter on after. I actually purchased the BRS RODI unit as a 5 stage RODI with a single DI canister as well as a three canister bracket and took the two DI canisters that I already had as well as the single canister that came with the new RODI unit and built my own 3 canister DI unit. I emailed BRS and asked if they could send me the sticker for their 3 canister DI filter and they were kind enough to do so

If you look closely you can see that one of the DI canisters actually has nothing in it right now. My intention is to switch to the single bed DI resin as the canister labels suggest, but I want to use up the mixed bed DI resin that I have first, so until that happens I’m just running two mixed bed DI canisters.

There is a DOS installed in the garage that controls the auto water change system

I elevated the DOS slightly because I recently installed an apex flood sensor right under it. This DOS is worked pretty hard. It changes about 3 gallons of water a day and moves the water through about 40 feet of tube to get it from the garage to the tank and then another 40 or 50 feet from the tank to the laundry room. It seems that the tube in the heads lasts about a year before they spring a leak and the head starts dripping whenever it runs. The first time it happened I wound up with a bit of a puddle on my garage floor because I didn’t catch it right away, but I figured it was just a fluke and changed the head and forgot about it. Then about a year later the new head sprang a leak and I got another puddle. This time after I replaced the head I put the flood sensor right under the DOS so the apex will catch it right away and shut off the AWC and send me an email to notify me. Hopefully no more puddles this time

Just as a quick note, I don’t think that this is really an inherent problem with the DOS. I think it’s just because I’m seriously overworking this unit with the fact that it’s moving so much water every day and it’s moving it over such a long distance. I have another DOS that I use to dose two part at much lower quantities and over a much shorter distance. That one has been in service for close to three years on this tank and the one before it and it has never had a head start to leak.

Under the shelf (for lack of space anywhere else) I have installed five 120V solenoid valves that are controlled by an apex EB8.

These are the heart of what automates my RODI filter and my ATO system.

The single solenoid was recently added and that’s the one that controls the RO membrane auto flush. The flow restrictor on the waste line is bypassed through that solenoid valve. Normally the valve is closed, so the waste water is forced through the flow restrictor and the RO membranes make water as normal, but whenever the RODI unit is on the apex will open the solenoid for 18 seconds of every hour to allow waste water to exit unrestricted and flush the membranes, which is supposed to help increase the life of the membranes. (For what it’s worth, BRS sells a standalone automatic flush valve and it operates for 18 seconds each hour, so that’s where I got those numbers. I had no idea how long it should run, but I assume that the manufacturer of that unit did some research to determine that flush time)

There is another solenoid that controls my auto top off. The auto top off is gravity fed from the reservoir on the shelf in the garage.

This reservoir holds about 20 gallons and is automatically refilled by the apex whenever it runs low. There is a siphon line in the reservoir that goes through the solenoid, then up into the attic and over to the tank, then through a float valve in the return pump section sump.

I have a few failsafes in place to help ensure that there are no floods from the automated system. The float valve is the first line of defense. When the water is at the correct level the float valve is closed and no water comes in. Additionally the apex only turns on the solenoid that runs the ATO for 2 minutes every 10 minutes. Because the system is gravity fed and it has to cover a long distance the water comes out at a very slow trickle. Running for 2 minutes every 10 minutes provides only slightly more water than is normally required to make up for evaporation. Even if the float valve were to fail, because the solenoid valve stays off most of the time the water level in the sump would only rise very slowly and it would be days before it could overflow. I also have two high level float switches in the sump that would alert me when the water level is starting to rise well before the sump would actually flood. One float switch is set at just slightly above the normal operating level and one is closer to the top of the sump and would indicate a more urgent situation. If either float switch is tripped the apex shuts off the ATO and notifies me of the problem.

Last edited: