The waterproofing membrane made it here in perfect timing. I was almost at a stand still,

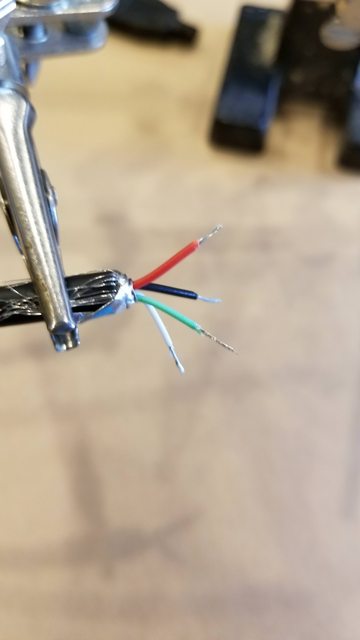

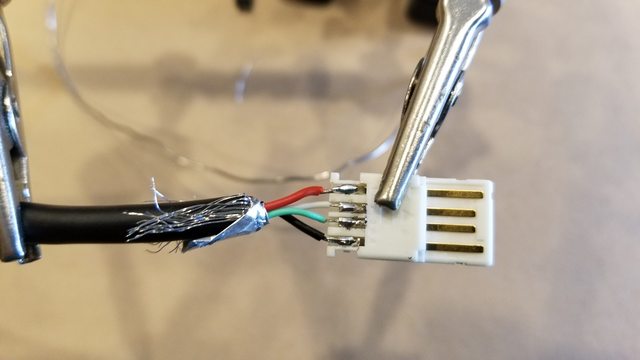

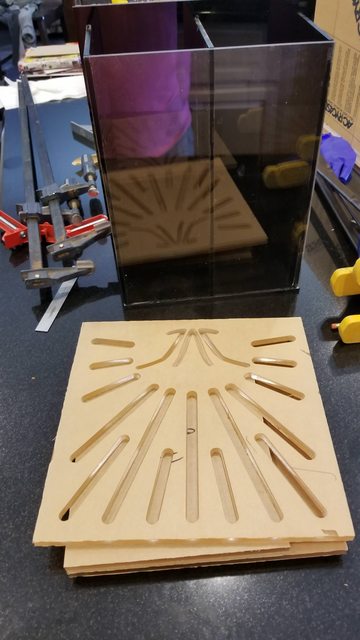

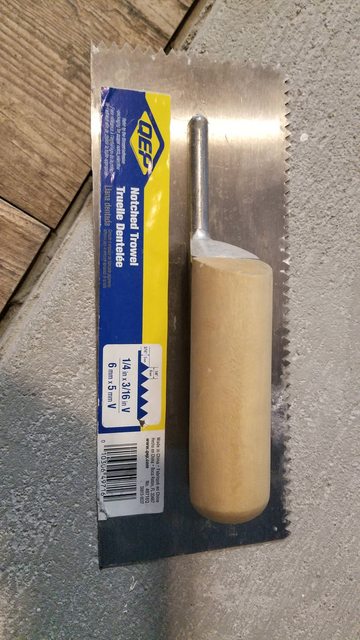

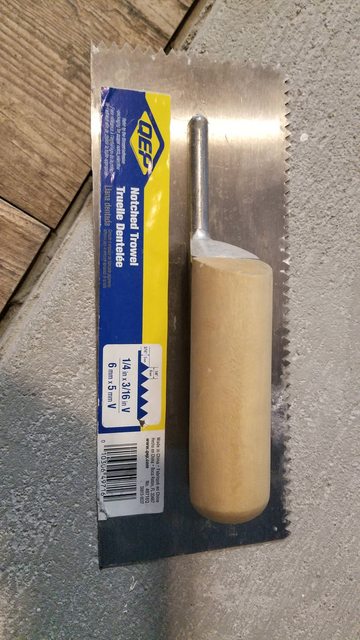

This is the trowel that the company recommends to provide a thin layer of thinset in between to provide good adhesion.

I went 4" up the wall, if any water leaks and collects on the step, it isn't going to seep into the walls, it will either sit there until I clean it up or if I did things right is will slope down and onto the floor.

A little clean up and later this evening I can put in the grout.

Just a little more insight of how I'm going to keep water from seeping into any other wall that is on ground surface. I always have to keep in the back of my mind that when it's time to take the tank down, that room has to be converted back into a closet. The gaps where the floor and wall meet are going to be filled with spray foam which is more to keep the bugs out, immediately after the foam has been sprayed and before it expands, I nail the base board down. Then I caulk the top AND bottom of the base board to seal the floor, keeping any standing water from making its way to the walls. If I do all this correctly, in the event of a flood the way that the room is sightly sloped, it will collect in the back of the room. In a catastrophic failure, nothing is going to help, I'll just be squeegee-ing water outside... hehe.

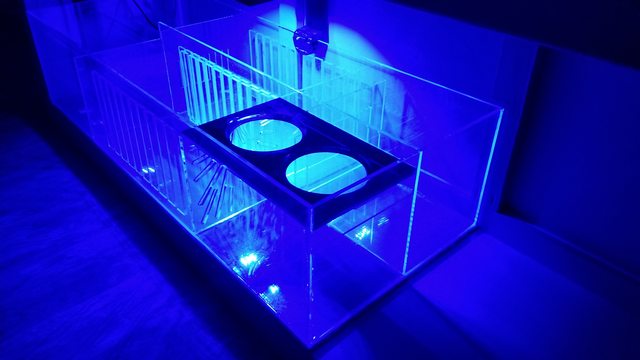

I'd like to think that the room will be completely done soon, which means I can finally turn my attention to the tank.

This is the trowel that the company recommends to provide a thin layer of thinset in between to provide good adhesion.

I went 4" up the wall, if any water leaks and collects on the step, it isn't going to seep into the walls, it will either sit there until I clean it up or if I did things right is will slope down and onto the floor.

A little clean up and later this evening I can put in the grout.

Just a little more insight of how I'm going to keep water from seeping into any other wall that is on ground surface. I always have to keep in the back of my mind that when it's time to take the tank down, that room has to be converted back into a closet. The gaps where the floor and wall meet are going to be filled with spray foam which is more to keep the bugs out, immediately after the foam has been sprayed and before it expands, I nail the base board down. Then I caulk the top AND bottom of the base board to seal the floor, keeping any standing water from making its way to the walls. If I do all this correctly, in the event of a flood the way that the room is sightly sloped, it will collect in the back of the room. In a catastrophic failure, nothing is going to help, I'll just be squeegee-ing water outside... hehe.

I'd like to think that the room will be completely done soon, which means I can finally turn my attention to the tank.