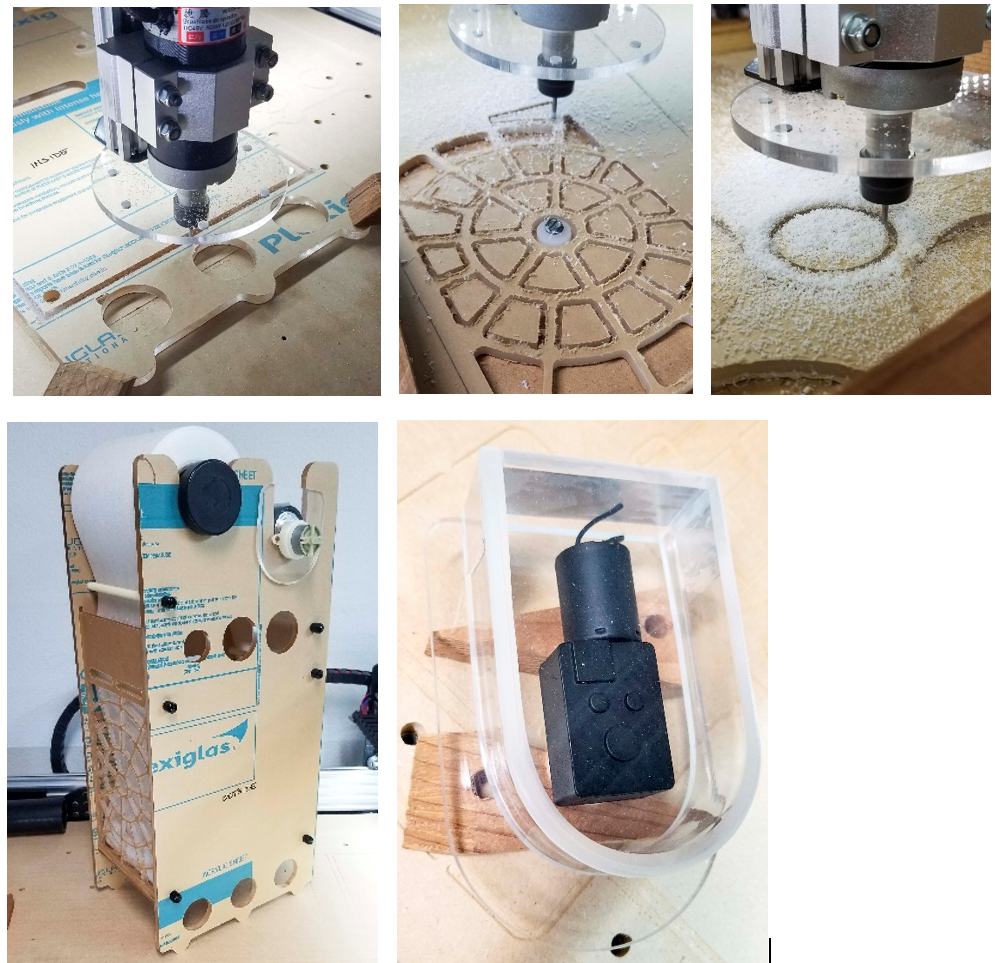

Planning a new build, this will go into new construction home in my home office. House plans are done but have time to make slight modifications is necessary. I previously had a fish only saltwater 90gal some 30 years ago. It was up for 5 years. Life took its course we moved and it didn't go back up. Now I would like a tank again. Thinking fish and soft corals with LPS in the future. I work in the engineering space with a background in manufacturing. So, I a few fabrication skills. I built an acrylic CNC in the garage. I have been doing tank research and cannot believe the advancements that have taken place. This tank would start going together late August but I have already started the DIY projects.

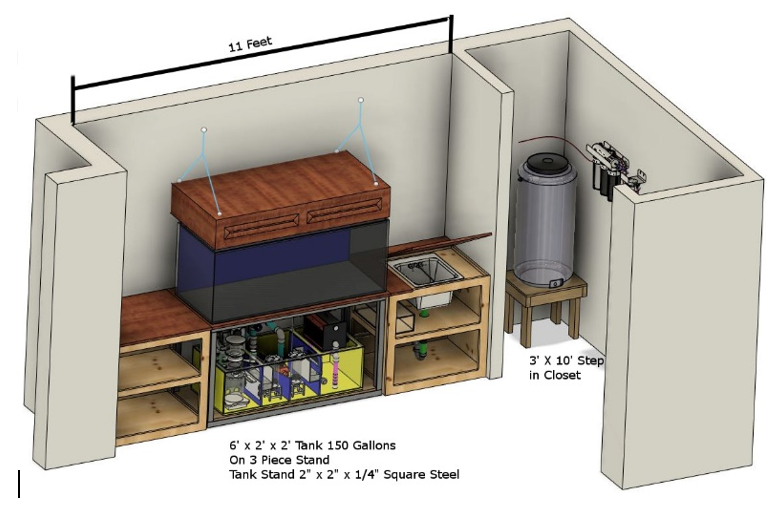

So here it is. The tank wall is 11 feet long and it has a 36 inches available depth. There is a step-in closet to the right that will be used for mixing, RO/DI water and QT Tank. Think of keeping it close. I am having a wet bar plumbed in on the right side of the tank wall with a lift up counter top for access. This for a water supply, a cleaning sink and waste water drain.

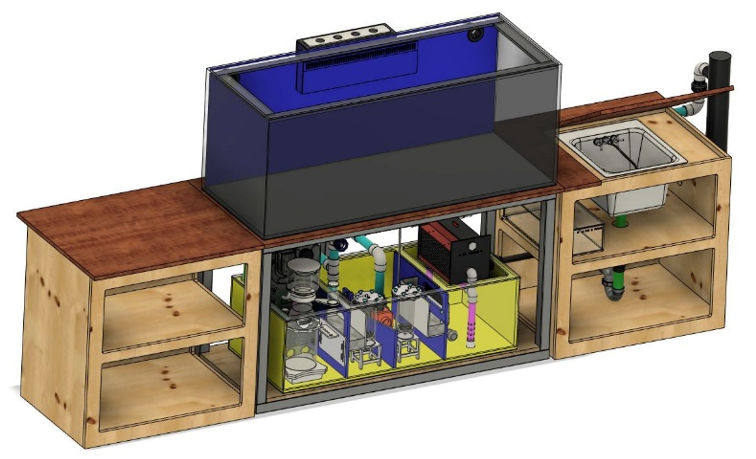

Below, I remove the walls the light hood, mixing and RO/DI units and isolated the main three-sections of the build. The center section is a 62” long supported by a 2” x 2” x ¼” steel tubing frame with no front center leg. It will support a 60” x 24” x 24” 150g DT. On either side will be a wood constructed shelving / storage unit. (Shelves and dividers not fully decided yet). They will have decorative doors on the front (not shown)

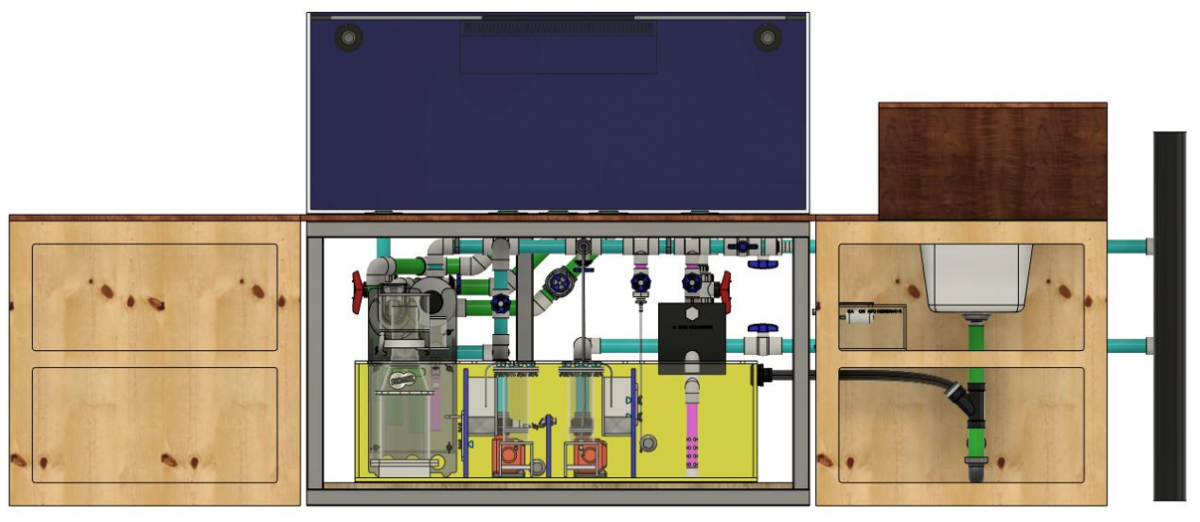

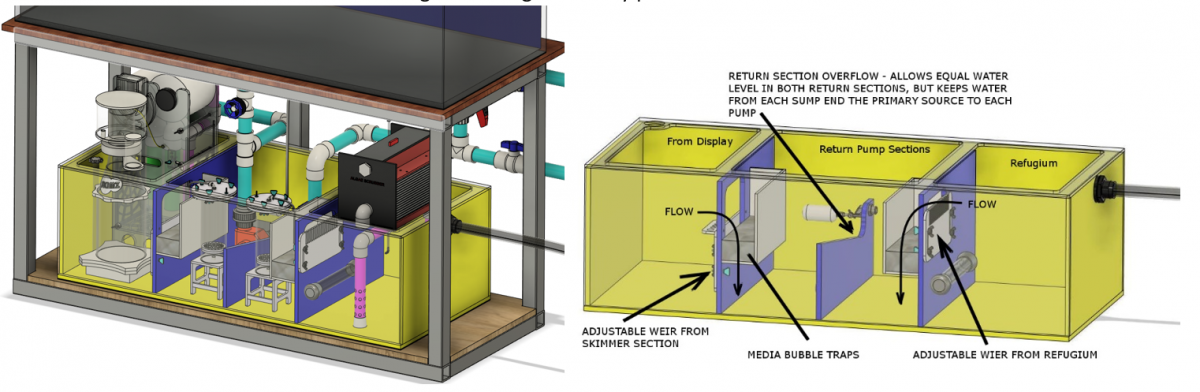

A 48” X 21” x 14” sump (Yellow) will be located beneath the tank. This will have an overflow section with water coming from the DT, a 2-part return section in the middle with dual return pumps and on the right a dual purpose frag & rubble refugium section with an Algae scrubber above. Thinking auto water change and a UV sterilizer which is designed here to be plumbed in and located in the corner of the mixing room. You see it here as the walls were removed.

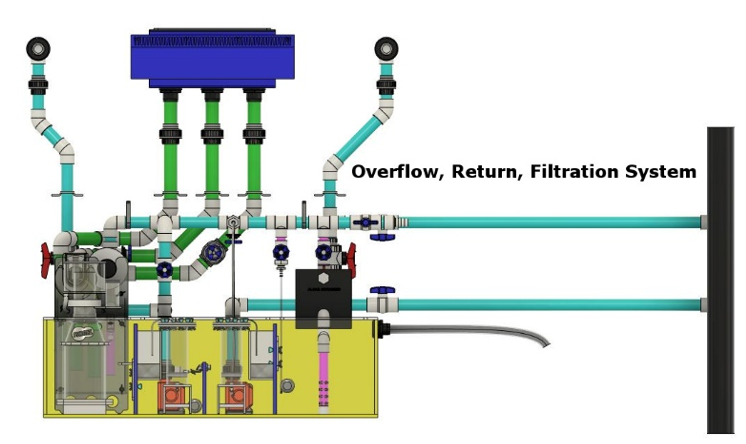

The Plumbing

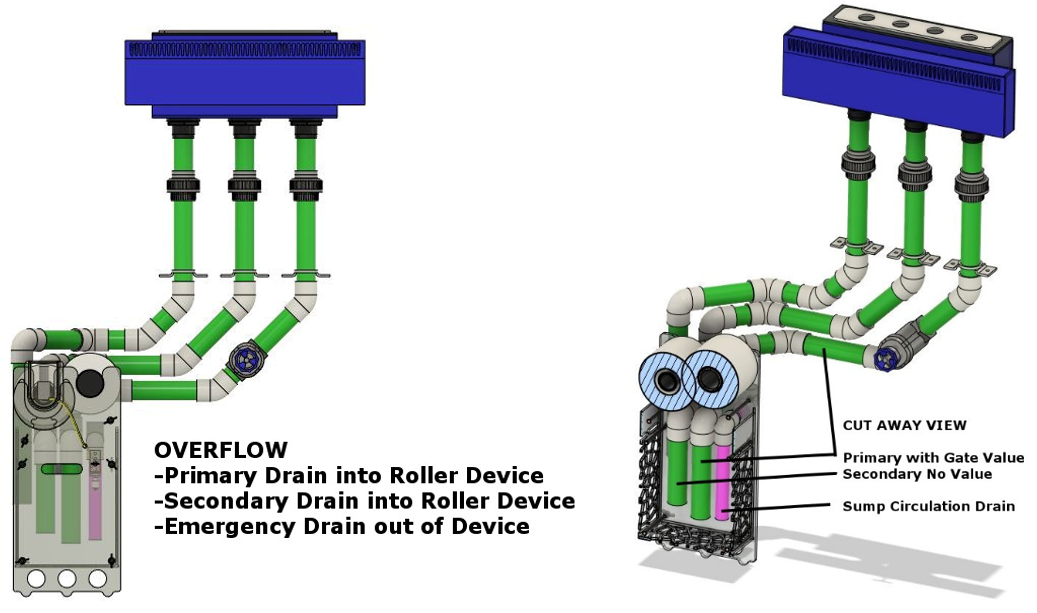

Starting with a 24” long DIY weir overflow box, similar to the 16” Ghost Overflow except longer and with different heights due to euro bracing on the tank. A Bean Animal drain system moving water to the sump. The primary having a gate valve is a 1 ½” PVC pipe going into the DIY roller filter device. The secondary also a 1 ½” PVC pipe going into the roller filter. Then the emergency that dumps directly into the sump outside the roller filter. The pink PVC is a re circulatory pipe explained later.

Each of the pipes have a support clamp just before the 45 elbow that attaches to the stand that will hold the weight of the plumbing and water from being all on the overflow box.

THE RETURN PLUMBING

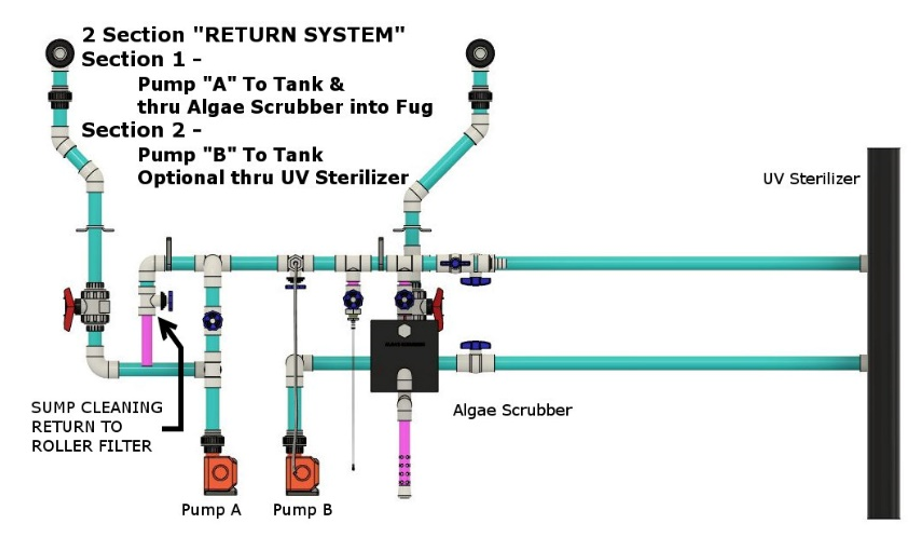

The return plumbing above all 1.25" PVC is 2 separate returns, each with its own pump. That from Pump “A” being separate from that of Pump “B”

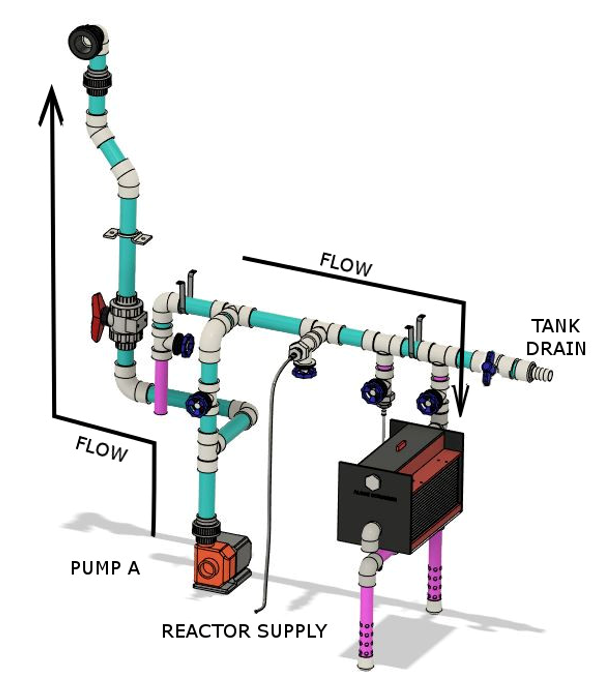

Pump “A” section (shown below) is the left pump and returns mechanically filtered water (roller filter and skimmer) back to the DT, and based on valves also into the manifold for reactors, algae scrubber, and the frag / rubble refugium. Ending into where Pump “B” returns it to the tank. I have added a valve and barb fitting at the end of the manifold to attach a hose for pumping the system out or in if needed (Tank Drain). I have also added a cleaning time recirculating pipe and valve “The Pink Pipe on the left that ends in the roller filter.” Pump “A” if the cleaning valve is open would send flow back into the roller filter for when I clean the sump and stir up everything it will re filter and remove the debris.

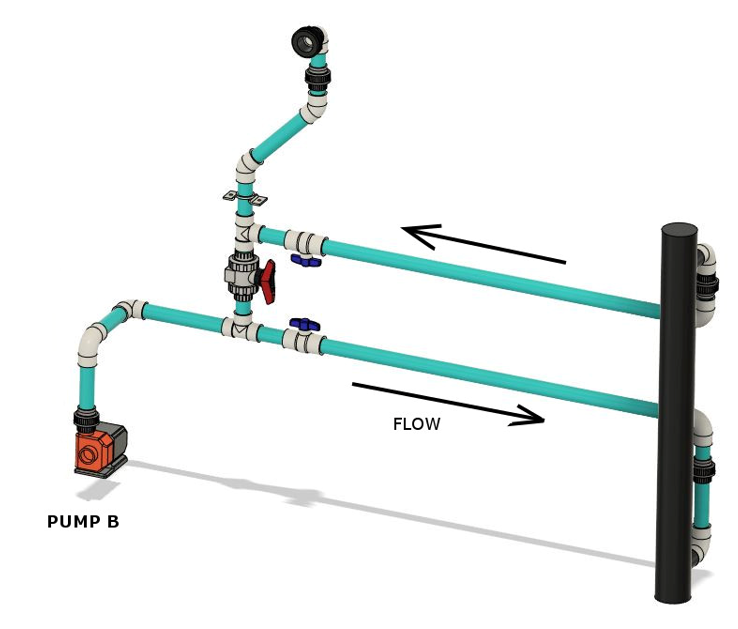

Pump “B” (below) pushes mechanically and biologically filtered water from sump up to DT, this line also has the optional UV sterilizer inline.

SUMP DESIGN

The sump is 3 / 4 sections – the left one will have the roller filter in the rear and the protein skimmer in front. Water passing through both of those devices will flow over an adjustable height weir through a filter floss bubble reducing media and into the left side of the center section / return section. The center two sections are both return sections with Pump “A” on the left and pump “B” on the right. The height of the divider in the middle is below the water line and is there to direct the majority of the water flowing in each section to the pump located in that section. If a higher volume of water is needed on either side it will be equalized by flowing over the center divider. (Thinking about and adjustable weir on this wall to add better control of the overflow). I am also adding a bulkhead overflow fitting on the right side of the sump that would be connected to a “P”-trap drain for unforeseen flooding conditions. With the wet bar drain so close I figure it is a good safety protocol. Never have an overflow from the Sump.

The center divider shape has a rise in the back to hold the ATO water valve (note the float valve in the rear). The DC dual pumps are first and foremost to ensure flow continues in case of a single pump failure. It will also allow adjustment to Pump “B” for the proper water flow through the UV sterilizer.

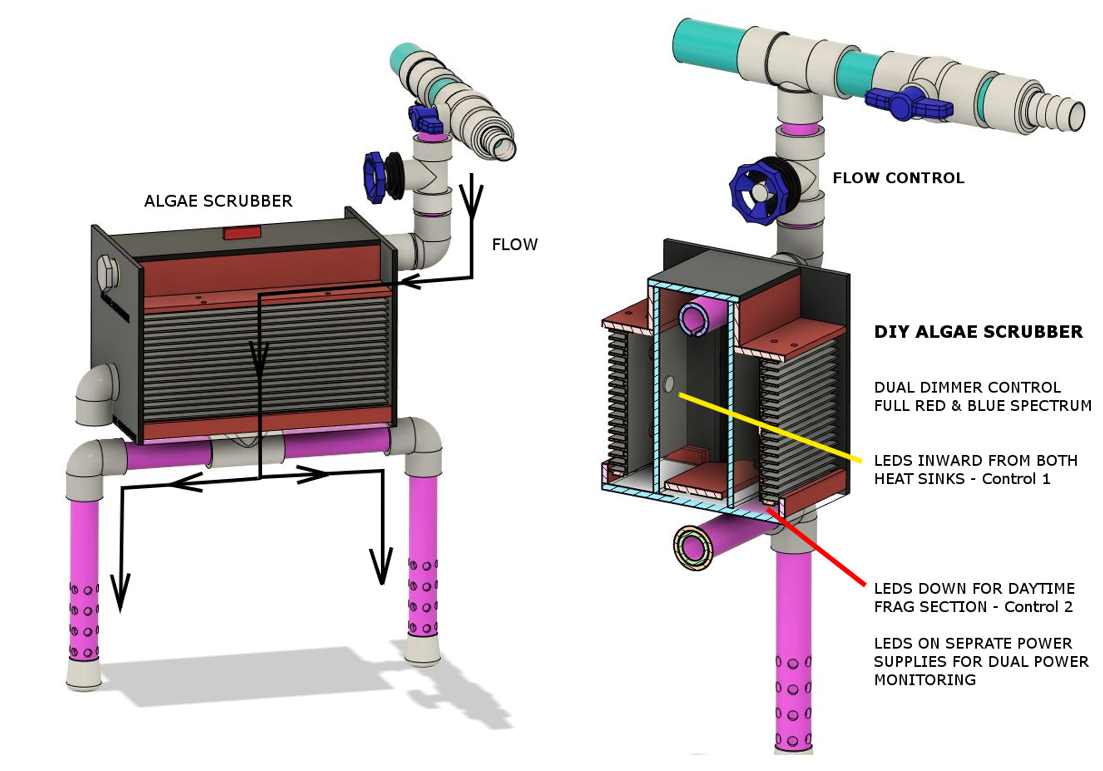

A heater will be placed in the refugium and one of the return sections. Over the refugium is a DIY Algae Scrubber that will take water from Pump “A” / manifold. Within the scrubber water will fall over a grid media that is between the two LED covered heat sinks. These LED’s banks are configured for the algae growth light spectrum. With adjustable blue / red spectrum control. There is a totally separate configured and adjustable LED bank facing down from the heat sinks into the frag / rubble refugium.

I have been doing my research and hopefully have not overthought this. Please provide feedback.

FYI.. a few picks of the DIY Roller Filter Machine

Thanks Ron

So here it is. The tank wall is 11 feet long and it has a 36 inches available depth. There is a step-in closet to the right that will be used for mixing, RO/DI water and QT Tank. Think of keeping it close. I am having a wet bar plumbed in on the right side of the tank wall with a lift up counter top for access. This for a water supply, a cleaning sink and waste water drain.

Below, I remove the walls the light hood, mixing and RO/DI units and isolated the main three-sections of the build. The center section is a 62” long supported by a 2” x 2” x ¼” steel tubing frame with no front center leg. It will support a 60” x 24” x 24” 150g DT. On either side will be a wood constructed shelving / storage unit. (Shelves and dividers not fully decided yet). They will have decorative doors on the front (not shown)

A 48” X 21” x 14” sump (Yellow) will be located beneath the tank. This will have an overflow section with water coming from the DT, a 2-part return section in the middle with dual return pumps and on the right a dual purpose frag & rubble refugium section with an Algae scrubber above. Thinking auto water change and a UV sterilizer which is designed here to be plumbed in and located in the corner of the mixing room. You see it here as the walls were removed.

The Plumbing

Starting with a 24” long DIY weir overflow box, similar to the 16” Ghost Overflow except longer and with different heights due to euro bracing on the tank. A Bean Animal drain system moving water to the sump. The primary having a gate valve is a 1 ½” PVC pipe going into the DIY roller filter device. The secondary also a 1 ½” PVC pipe going into the roller filter. Then the emergency that dumps directly into the sump outside the roller filter. The pink PVC is a re circulatory pipe explained later.

Each of the pipes have a support clamp just before the 45 elbow that attaches to the stand that will hold the weight of the plumbing and water from being all on the overflow box.

THE RETURN PLUMBING

The return plumbing above all 1.25" PVC is 2 separate returns, each with its own pump. That from Pump “A” being separate from that of Pump “B”

Pump “A” section (shown below) is the left pump and returns mechanically filtered water (roller filter and skimmer) back to the DT, and based on valves also into the manifold for reactors, algae scrubber, and the frag / rubble refugium. Ending into where Pump “B” returns it to the tank. I have added a valve and barb fitting at the end of the manifold to attach a hose for pumping the system out or in if needed (Tank Drain). I have also added a cleaning time recirculating pipe and valve “The Pink Pipe on the left that ends in the roller filter.” Pump “A” if the cleaning valve is open would send flow back into the roller filter for when I clean the sump and stir up everything it will re filter and remove the debris.

Pump “B” (below) pushes mechanically and biologically filtered water from sump up to DT, this line also has the optional UV sterilizer inline.

SUMP DESIGN

The sump is 3 / 4 sections – the left one will have the roller filter in the rear and the protein skimmer in front. Water passing through both of those devices will flow over an adjustable height weir through a filter floss bubble reducing media and into the left side of the center section / return section. The center two sections are both return sections with Pump “A” on the left and pump “B” on the right. The height of the divider in the middle is below the water line and is there to direct the majority of the water flowing in each section to the pump located in that section. If a higher volume of water is needed on either side it will be equalized by flowing over the center divider. (Thinking about and adjustable weir on this wall to add better control of the overflow). I am also adding a bulkhead overflow fitting on the right side of the sump that would be connected to a “P”-trap drain for unforeseen flooding conditions. With the wet bar drain so close I figure it is a good safety protocol. Never have an overflow from the Sump.

The center divider shape has a rise in the back to hold the ATO water valve (note the float valve in the rear). The DC dual pumps are first and foremost to ensure flow continues in case of a single pump failure. It will also allow adjustment to Pump “B” for the proper water flow through the UV sterilizer.

A heater will be placed in the refugium and one of the return sections. Over the refugium is a DIY Algae Scrubber that will take water from Pump “A” / manifold. Within the scrubber water will fall over a grid media that is between the two LED covered heat sinks. These LED’s banks are configured for the algae growth light spectrum. With adjustable blue / red spectrum control. There is a totally separate configured and adjustable LED bank facing down from the heat sinks into the frag / rubble refugium.

I have been doing my research and hopefully have not overthought this. Please provide feedback.

FYI.. a few picks of the DIY Roller Filter Machine

Thanks Ron