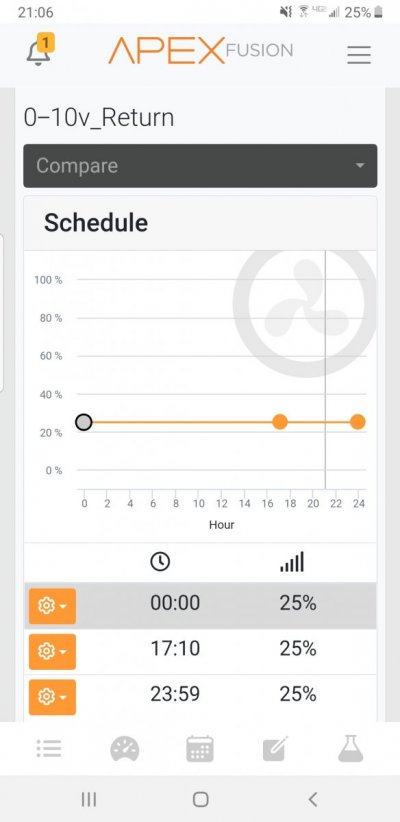

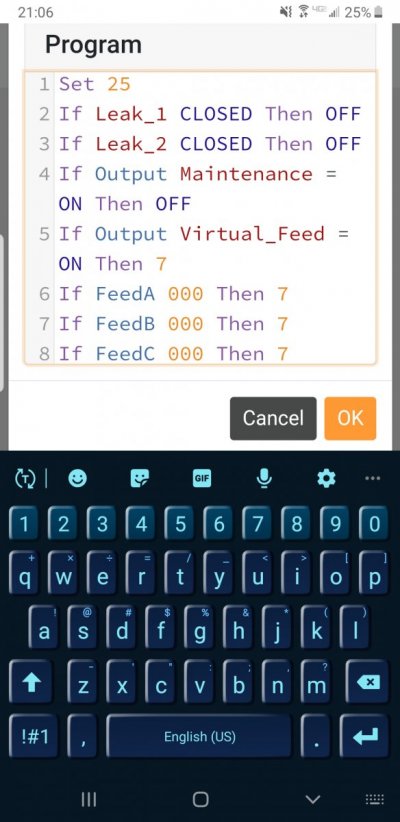

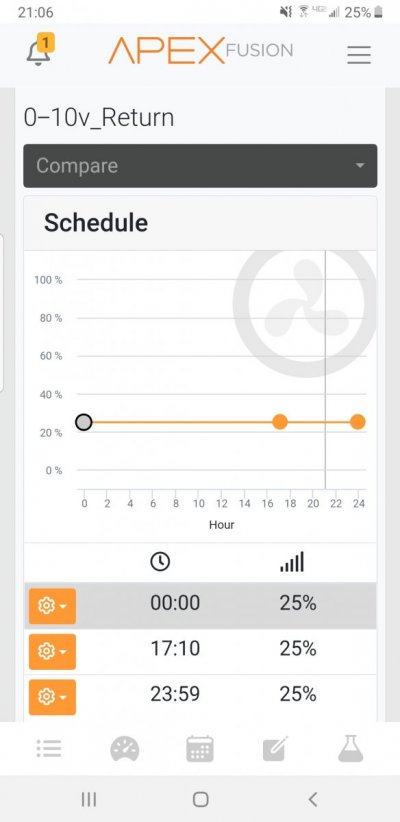

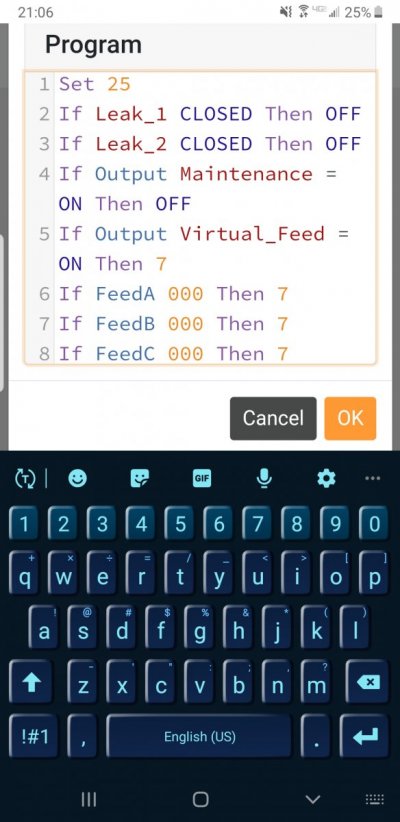

Please help. I am trying to use 0-10v control on my return pump and skimmer (both RO varios using icecap cable). Basically I want fine tuning, to keep the return line primed during feed modes, and I'd also like to keep them plugged into EB832 for power monitoring. I cannot figure this out... first they just turned off when I plugged in 0-10v cable. So I turned outlets (both variable speed and actual eb832 from auto to on) and they just seemed to both be at 100%. Can someone point me to a good tutorial on this (YouTube vids not really finding anything, apex manual is outdated, couldn't find much here on reef2reef)? I am an Apex noob (obviously), so please be gentle. Attached pics of my variable speed outlet for return pump configuration. Help! Do I have to use a profile or just the configuration as per my attached pics? What should the programming look like for both variable speed outlet and regular outlet?