- Joined

- Dec 14, 2019

- Messages

- 80

- Reaction score

- 185

Hi All.

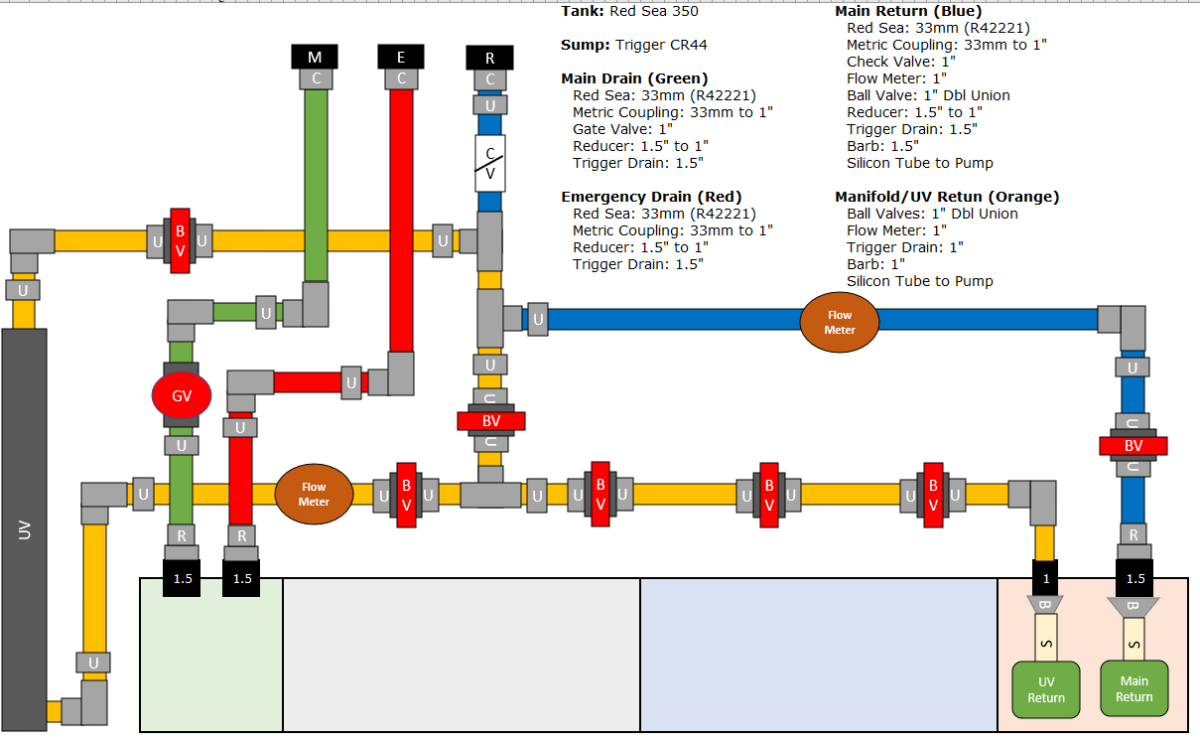

I’m in the process of moving my Red Sea 350 into my basement. This will allow me to setup a new Trigger CR44 sump in my workshop which is in the room behind the Display Tank wall. This mean I now have the pleasure of working out the plumbing that will hopefully be somewhat “future proof” …

So now for the fun ... I am looking for input on the below plumbing option. I have never tackled anything like this so any recommendations/guidance would be greatly appreciate.

I am planning for the majority of the pipe to be 1” and I will deal with any reductions/increases at sump (CR44 has 1.5” openings) & display (RS350 has 33mm after modification to R42221 part). I am also toying with the idea of two return pumps so that i can have better flow control for the manifold and UV sterilizer.

What do you think?

Two Pump Option:

I hope all my forum reading and YouTube watching has not sent me too far astray .

I’m in the process of moving my Red Sea 350 into my basement. This will allow me to setup a new Trigger CR44 sump in my workshop which is in the room behind the Display Tank wall. This mean I now have the pleasure of working out the plumbing that will hopefully be somewhat “future proof” …

So now for the fun ... I am looking for input on the below plumbing option. I have never tackled anything like this so any recommendations/guidance would be greatly appreciate.

I am planning for the majority of the pipe to be 1” and I will deal with any reductions/increases at sump (CR44 has 1.5” openings) & display (RS350 has 33mm after modification to R42221 part). I am also toying with the idea of two return pumps so that i can have better flow control for the manifold and UV sterilizer.

What do you think?

Two Pump Option:

I hope all my forum reading and YouTube watching has not sent me too far astray .