- Joined

- Jan 14, 2016

- Messages

- 89

- Reaction score

- 53

My boss (wife) gave me the green light to order a 150 gallon SCA aquarium and it will be here next week. It is a 5x2x2 tank drilled for the Shadow overflow. Since this is my "big upgrade" and is meant to last a long time I want to make sure the stand both looks good, and is as functional as possible. I want to go for more of a cabinet grade looking stand this time instead of the typical 2x4 construction stands I do. I looked around the forums, and while there are some great threads showing off plywood stands there are not nearly as many actual build threads as there are for rocket engineer's design. This will be my first build like this so I would like others who have built plywood stands to look this over to make sure everything seems right.

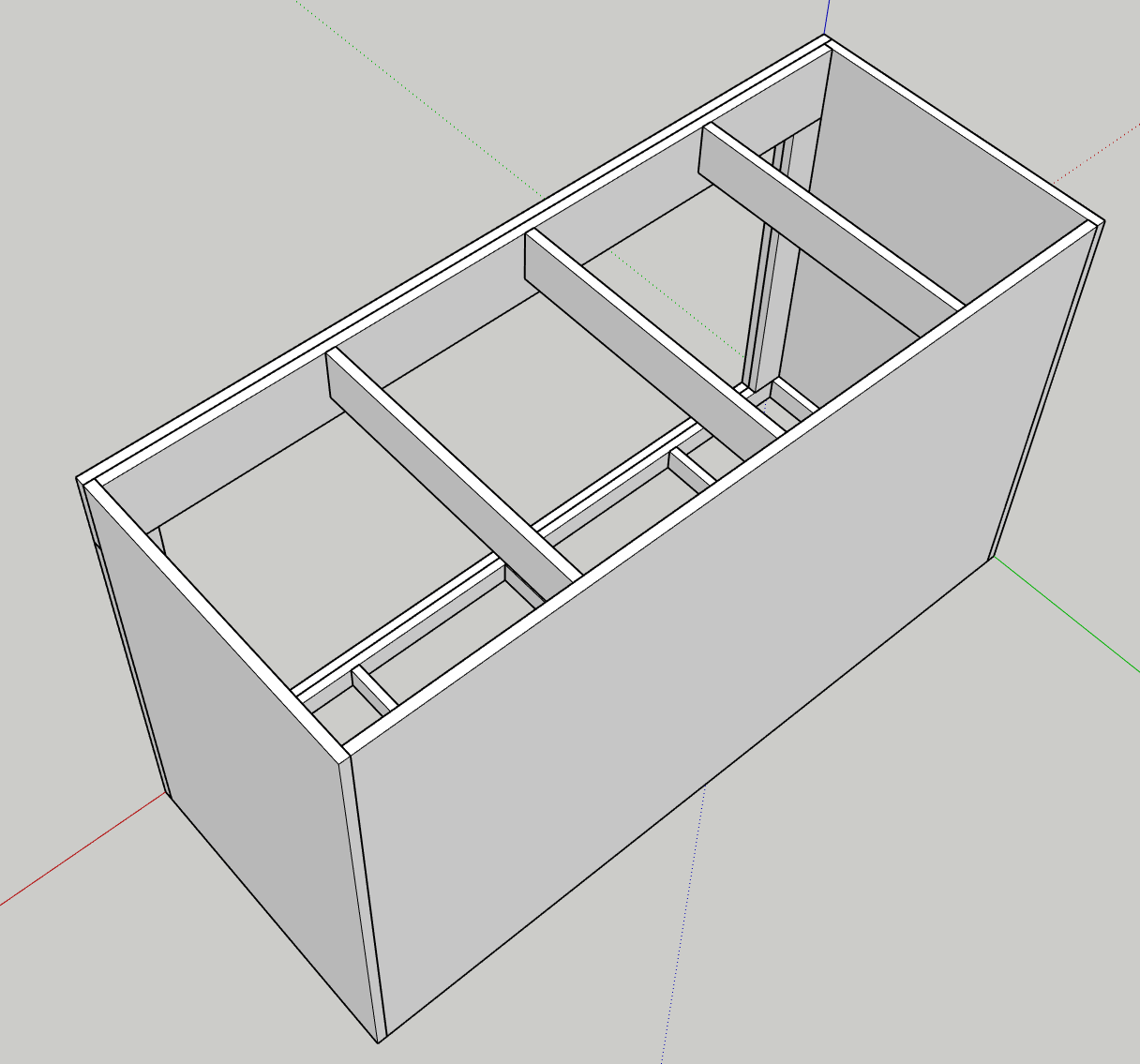

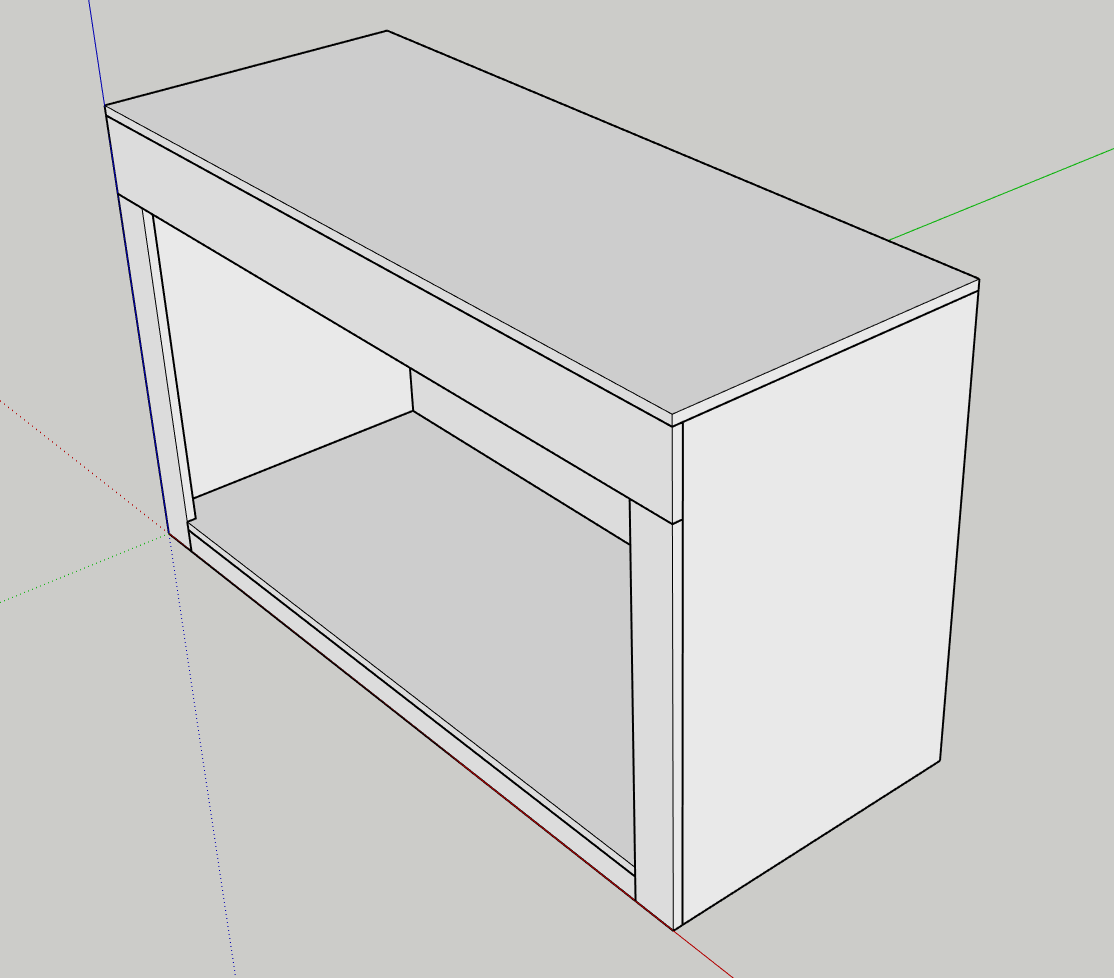

This is a picture of the frame, minus the top and bottom shelves to make it easier to see the structure. It is all 3/4 ply and joined with pocket holes and glue. The sides and back are just solid pieces while the front was built face frame style. The top cross beam is 6", bottom 2" and verticals are 3.5". the bottom shelf supports are also all 2" to align with the front. The top cross braces are 4". With the top shelf on the stand will be 36" high and it will be 60" 1/4 x 24" 1/4 to allow for a 1/4" tolerance between the trim and aquarium.

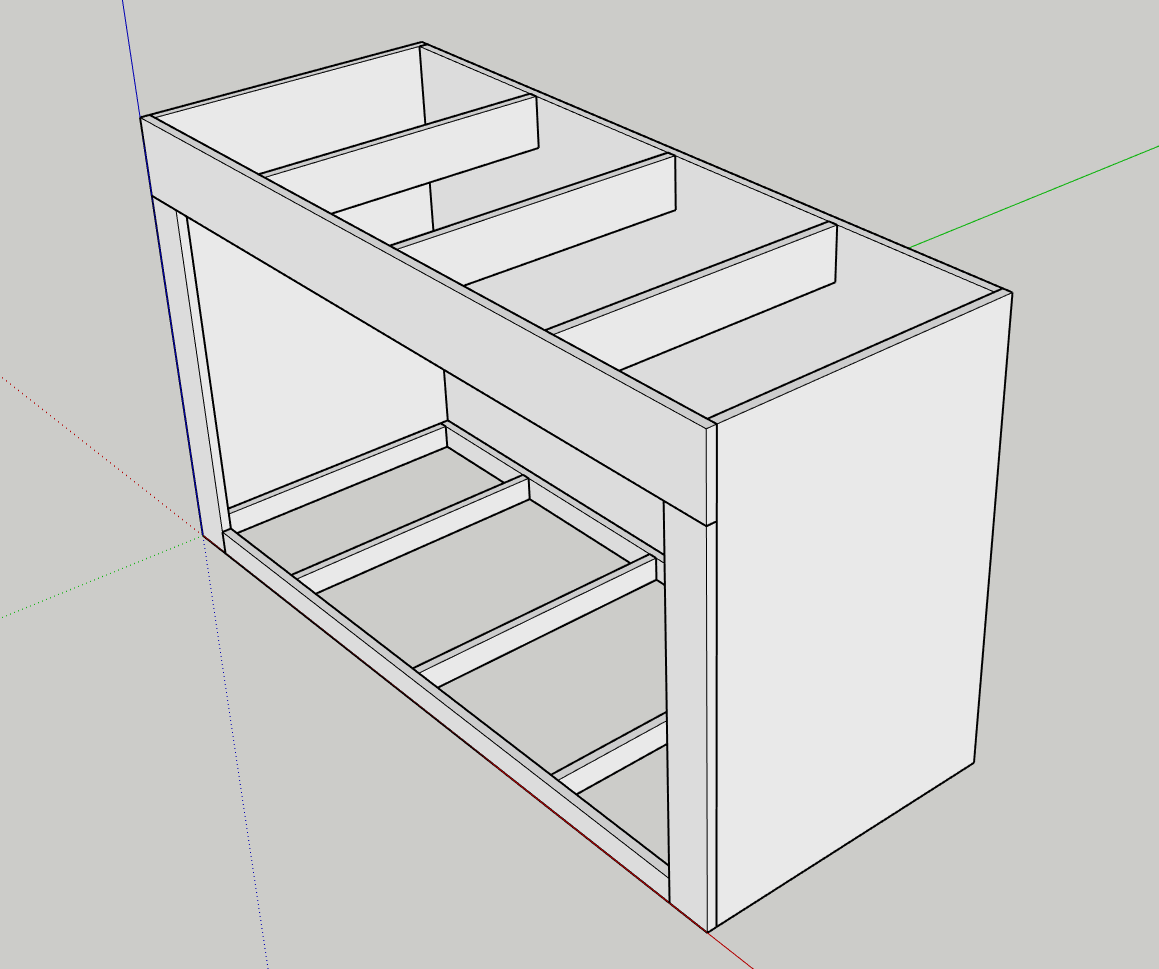

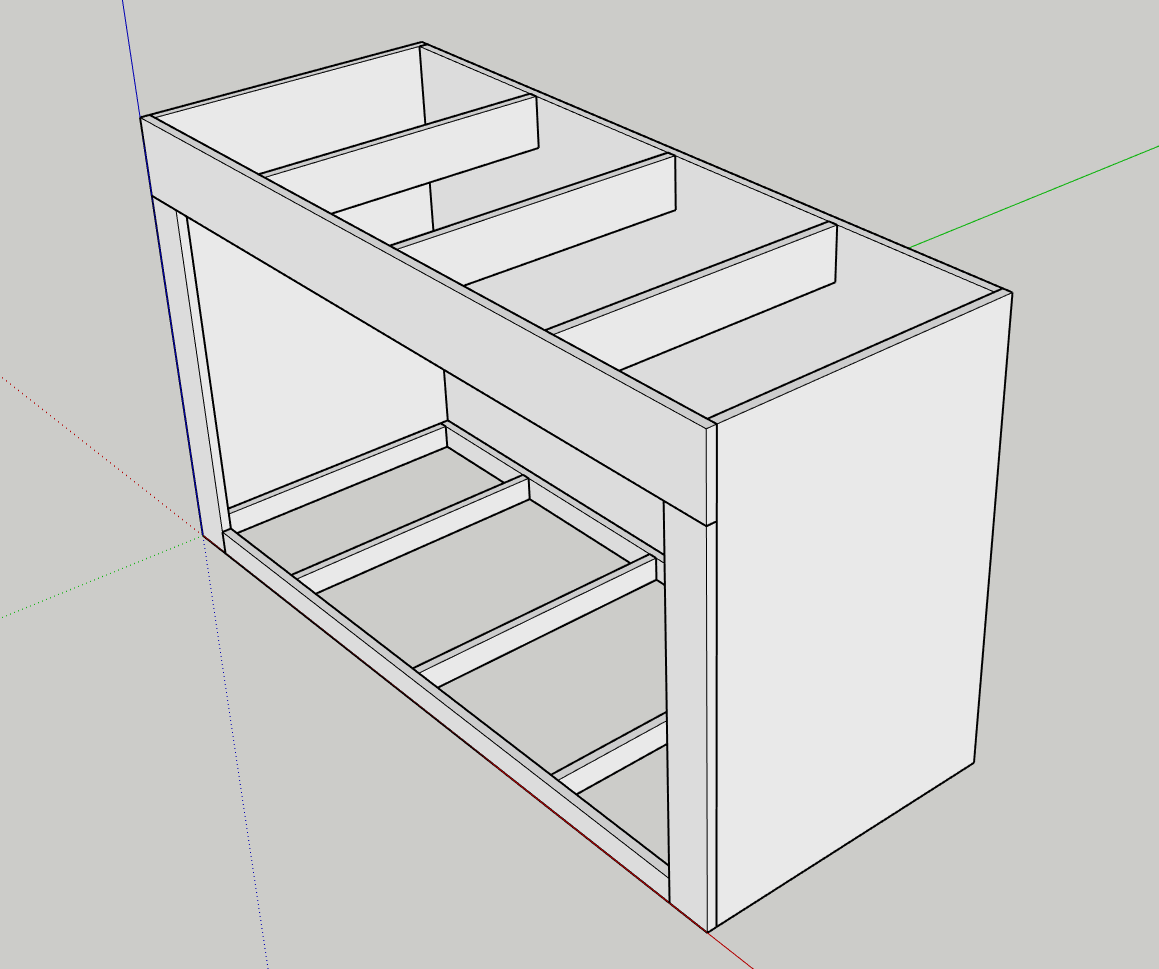

Here is another view with shelving.

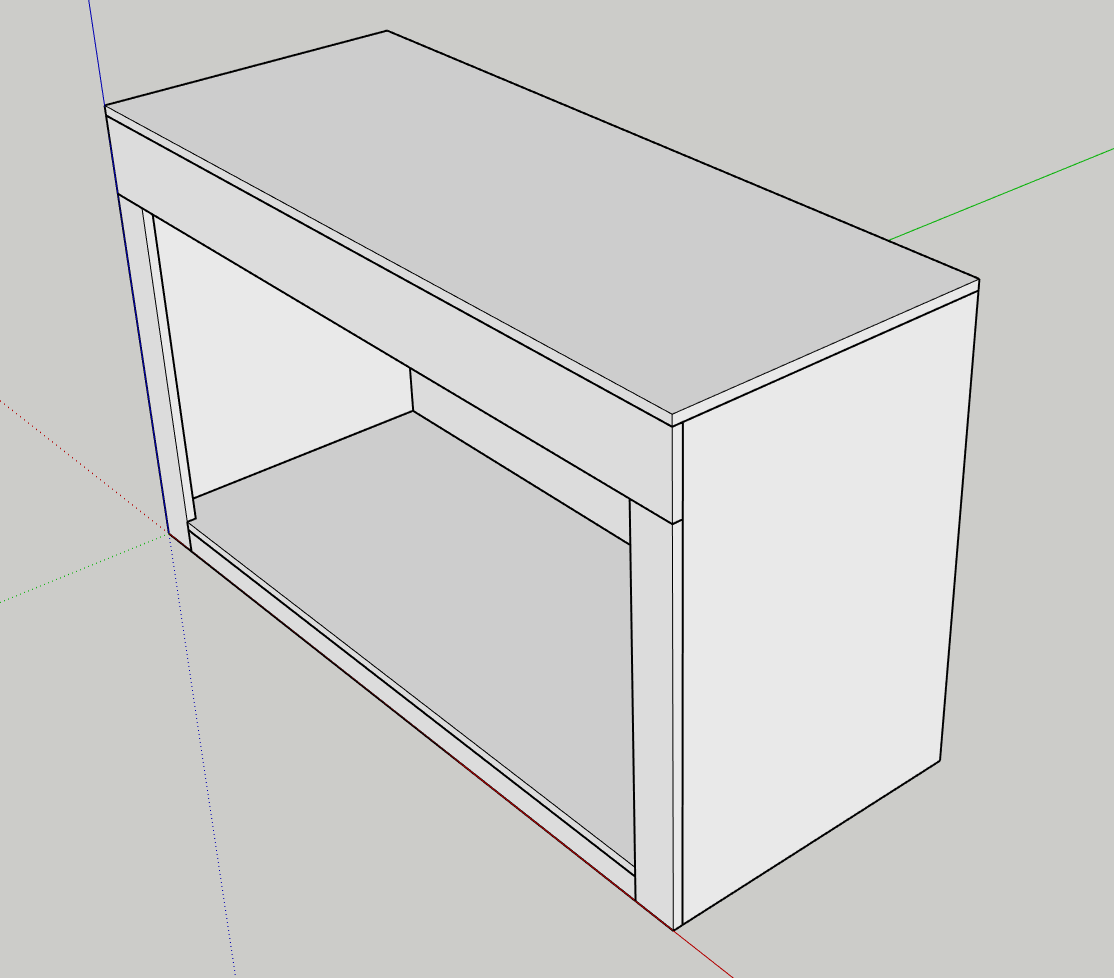

I did not plan to skin this in another layer of plywood. My goal was just to add decorative trim, doors and paint.

Is this good as is, or are there spots I need more support? I thought about doing a two layer laminate beam for the top cross brace, but want to avoid unnecessary wood/weight if it isn't needed. I also wanted to add doors to the sides, but then both sides would need to be built face frame style too and i was afraid that would weaken the structure too much and end up requiring all the pieces to be laminated and doubled up.

Thoughts?

This is a picture of the frame, minus the top and bottom shelves to make it easier to see the structure. It is all 3/4 ply and joined with pocket holes and glue. The sides and back are just solid pieces while the front was built face frame style. The top cross beam is 6", bottom 2" and verticals are 3.5". the bottom shelf supports are also all 2" to align with the front. The top cross braces are 4". With the top shelf on the stand will be 36" high and it will be 60" 1/4 x 24" 1/4 to allow for a 1/4" tolerance between the trim and aquarium.

Here is another view with shelving.

I did not plan to skin this in another layer of plywood. My goal was just to add decorative trim, doors and paint.

Is this good as is, or are there spots I need more support? I thought about doing a two layer laminate beam for the top cross brace, but want to avoid unnecessary wood/weight if it isn't needed. I also wanted to add doors to the sides, but then both sides would need to be built face frame style too and i was afraid that would weaken the structure too much and end up requiring all the pieces to be laminated and doubled up.

Thoughts?