Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

preview of 800 g tank in 3 rooms

- Monster Build

- Thread starter FishTruck

- Start date

- Tagged users None

This is amazing . Dreams here of building my house around my tank !

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

Are those homemade wooden sumps? Did you previously post about them and if so on what page? Looks really awesome!

Yes... those are homemade plywood sumps. That was an ordeal. I did not really post much about them. I basically followed the "king of DIY" with a few modifications. Regarding those modifications... I should post a series on how NOT to build wooden sumps. Maybe, I will. Here are the mistakes I made along the way.

1. I started with grey pond armor (it was cheaper). Covering this with white until it looked decent took lots of material. It would have been cheaper to just go with white and saved me probably four days right there. You can still see grey peaking through on the corners and other hard to cover areas.

2. I used 2 x 4 s to make something like Eurobracing over the top of two of the sumps, where I hope to grow frags. This worked reasonably well. Since they are above the waterline... I just rounded the outside corners with a router and pond armored them.

For the two utility sumps, I rain 2 x4 rails to both act as support and also hold the trays under the autocad filters. This was a real challenge. Waterproofing flat surfaces is easy. Corners, both inside and outside are much harder. It literally took me an extra three weeks to get this right. Basically, all corners need to be rounded down. All gaps filled and fiber-glassed. And, plan on working at weird angles to get the stuff on the upside down surfaces if you are doing anything besides a box... like... a sump for example...

Fiberglass. I can't even start to explain how much I learned with this stuff. I ended up using the MAT type stuff which I had to special order. Going around outside corners is very difficult... since the glass tends to lift. This was crucial, since I knew I would be beating on the outside corners of the 2 x 4 tray rails. I applied and ripped out fiberglass on those rails more times than I can remember. I will remember the rashes forever. Make sure to wear full body protection when you work with real fiberglass.

3. You can't mess around with mixing epoxy. Trying to go fast does not pay. Get it just one coat wrong.... and you ruin your project. I did that. My fourth coat on my first try did not set. I had to peel everything off with a heat gun and chisel on all four boxes and start all over. Doing ONE box at at time is the smart move. Trying to hop around and get four boxes coated with each epoxy mix was just stupid.

4. Bulkheads. Four of my six bulkheads leaked. The cheaper ABS ones specifically. I found that the area around the bulkheads needs to be sanded down to a 220 or finer grit, made "glass like", and then the bulkheads work.

The weekends of the months of November and December were basically lost on these things. I do like them now though. They did not leak (other than the bulkheads), and the are very rigid. There is no bowing at all.

If I ever build another sump... I will go back to acrylic! Or, if I could find SOLID pvc sheets, I would to that or any dang thing but plywood!

Last edited:

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

I moved all the live rock from the old system sump to the new system sump April 1st. Enough to fill it. Hopefully, the new dry rock in the display is starting to get colonized.

Yesterday, I brought over the calcium reactor. I'll fire that up and try to dissolve the precipitate that I made by making 1200 gallons of saltwater to quickly.

This weekend or next... I'll grab the lights from the old system and bring over corals and put them downstairs. The fish will go in the main display. No lights in the main display for another two or three weeks.

I have lots of things to share about what has happened in the past two weeks and I'll get to work on that too. With pictures to make it more interesting. Cheers.

Yesterday, I brought over the calcium reactor. I'll fire that up and try to dissolve the precipitate that I made by making 1200 gallons of saltwater to quickly.

This weekend or next... I'll grab the lights from the old system and bring over corals and put them downstairs. The fish will go in the main display. No lights in the main display for another two or three weeks.

I have lots of things to share about what has happened in the past two weeks and I'll get to work on that too. With pictures to make it more interesting. Cheers.

Thanks for sharing your ordeal about the sumps. Much more interesting to hear struggle stories that got you the pretty awesome end result instead of giving us all false hope that its really easy to do because everything just magically comes together, when the reality is that is not usually the case. Keep the updates coming! love the build

crusso1993

7500 Club Member

View BadgesTampa Bay Reef Keepers

West Palm Beach Reefer

Hospitality Award

Ocala Reef Club Member

MAC of SW Florida

Yes... those are homemade plywood sumps. That was an ordeal. I did not really post much about them. I basically followed the "king of DIY" with a few modifications. Regarding those modifications... I should post a series on how NOT to build wooden sumps. Maybe, I will. Here are the mistakes I made along the way.

1. I started with grey pond armor (it was cheaper). Covering this with white until it looked decent took lots of material. It would have been cheaper to just go with white and saved me probably four days right there. You can still see grey peaking through on the corners and other hard to cover areas.

2. I used 2 x 4 s to make something like Eurobracing over the top of two of the sumps, where I hope to grow frags. This worked reasonably well. Since they are above the waterline... I just rounded the outside corners with a router and pond armored them.

For the two utility sumps, I rain 2 x4 rails to both act as support and also hold the trays under the autocad filters. This was a real challenge. Waterproofing flat surfaces is easy. Corners, both inside and outside is much harder. It literally took me an extra three weeks to get this right. Basically, all corners need to be rounded down. All gaps filled and fiber-glassed. And, plan on working at weird angles to get the stuff on the upside down surfaces.

Fiberglass. I can't even start to explain how much I learned with this stuff. I ended up using the MAT type stuff which I had to special order. Going around outside corners is very difficult... since the glass tends to lift. This was crucial, since I knew I would be beating on the outside corners of the 2 x 4 tray rails. I applied and ripped out fiberglass on those rails more times than I can remember.

3. You can't mess around with mixing epoxy. Trying to go fast does not pay. Get it just one coat wrong.... and you ruin your project. I did that. My fourth coat on my first try did not set. I had to peel everything off with a heat gun and chisel on all four boxes and start all over.

4. Bulkheads. Four of my six bulkheads leaked. The cheaper ABS ones specifically. I found that the area around the bulkheads needs to be sanded down to a 220 or finer grit, made "glass like", and then the bulkheads work.

The weekends of the months of November and December were basically lost on these things. I do like them now though. They did not leak (other than the bulkheads), and the are very rigid. There is no bowing at all.

If I ever build another sump... I will go back to acrylic! Or, if I could find SOLID pvc sheets, I would to that.

Great write up on your "fun" with the sumps!

I learned quite a bit of the same lessons, over the years, of building plywood tanks. However, I think you beat me on the frustration part.

I see the CADS cloth rollermat! I have one too. What do you think of it, and can you share more pictures of how it’s set up? I’ve had mine running three months and like it.

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

I see the CADS cloth rollermat! I have one too. What do you think of it, and can you share more pictures of how it’s set up? I’ve had mine running three months and like it.

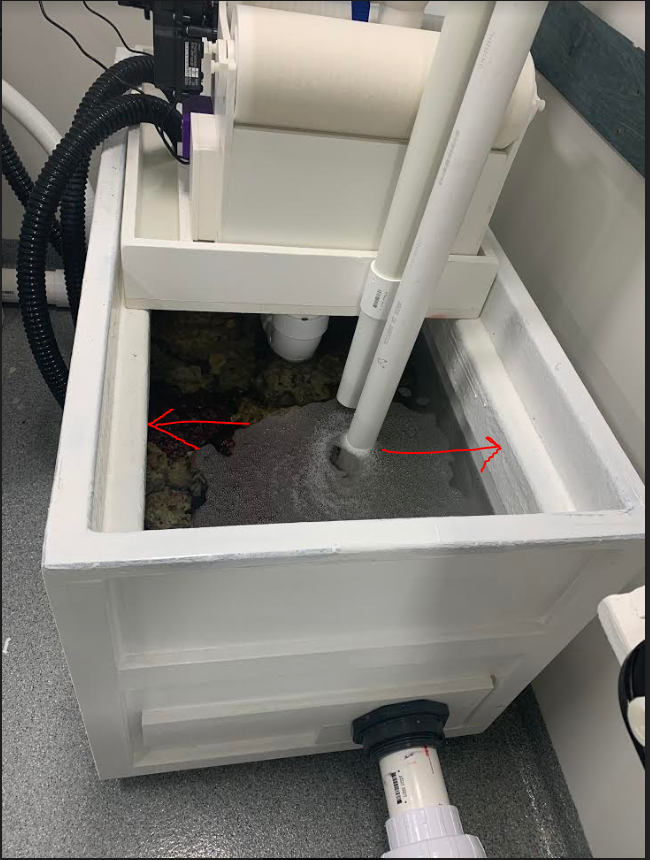

Here they are. So far... I like them. BUT.... I have overwhelmed them with flow a few times - so I'm trying to figure out how much they can really handle, and how to keep the flow even. You can see the one on the left has rolled through a bunch more material.

These are at the bottom of the siphon part of the overflow.

In the first pic you can see the PVC tray that I build for them. I cut four holes, each with a three inch PVC pipe to elbow to cushion the impact of water falling to the sump (makes them quieter).

The black flexible tubes are the returns from my frag tanks, currently bypassing the CADs.

The next picture shows how I plumbed them.... The top red gate valve is to adjust the siphon (it's a modified bean), the second one is a shutoff and will also let me divert some of the flow away later, if needed (you can see the TEE which I capped off). If the flow gets turbulent and roils - they get overwhelmed and run too fast. Also, if one side gets into a full siphon, it will steal all the water from the other side. I am still tweaking that part of it. I do have room for a third one if needed.

That sounds like a challenge.

I just have one and it is fed from the fuge directly above so no siphon for me. I also made a tray with a bulkhead and elbow pipe underneath to quiet it down. Have you thought about running your tank drains to drain box above the cads and then just using simple standpipes to feed the cads?

Have you figured out what the blue bars are for? Mine broke and is long gone.

I just have one and it is fed from the fuge directly above so no siphon for me. I also made a tray with a bulkhead and elbow pipe underneath to quiet it down. Have you thought about running your tank drains to drain box above the cads and then just using simple standpipes to feed the cads?

Have you figured out what the blue bars are for? Mine broke and is long gone.

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

1. I think I fixed the siphon problem by raising the pipes up just above the emergency overflow and diverting more of the flow away to the frag system. I still don't know why the flow sometimes switches from right to left and your drain box is a good idea. I have plenty of vertical space. Not sure about the blue bars, but, they did pull the sides back together by about 3 mm when I finally noticed them and installed them. Maybe support?? Gerry from Seavisions sells replacements. Maybe... i'll email him.That sounds like a challenge.

I just have one and it is fed from the fuge directly above so no siphon for me. I also made a tray with a bulkhead and elbow pipe underneath to quiet it down. Have you thought about running your tank drains to drain box above the cads and then just using simple standpipes to feed the cads?

Have you figured out what the blue bars are for? Mine broke and is long gone.

2. Emvanburen... how long do your CADs rolls last?

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

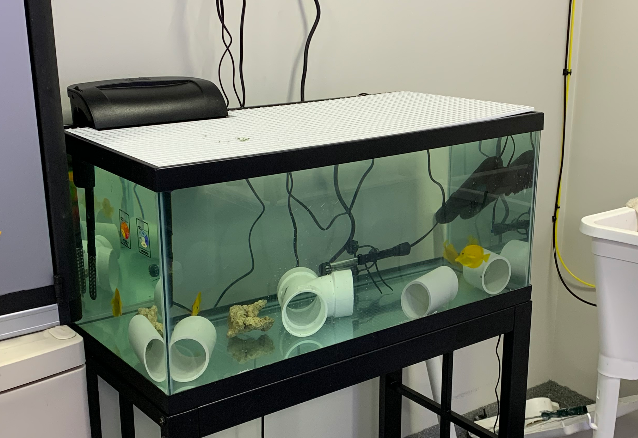

Fish from the old tank are moving in....

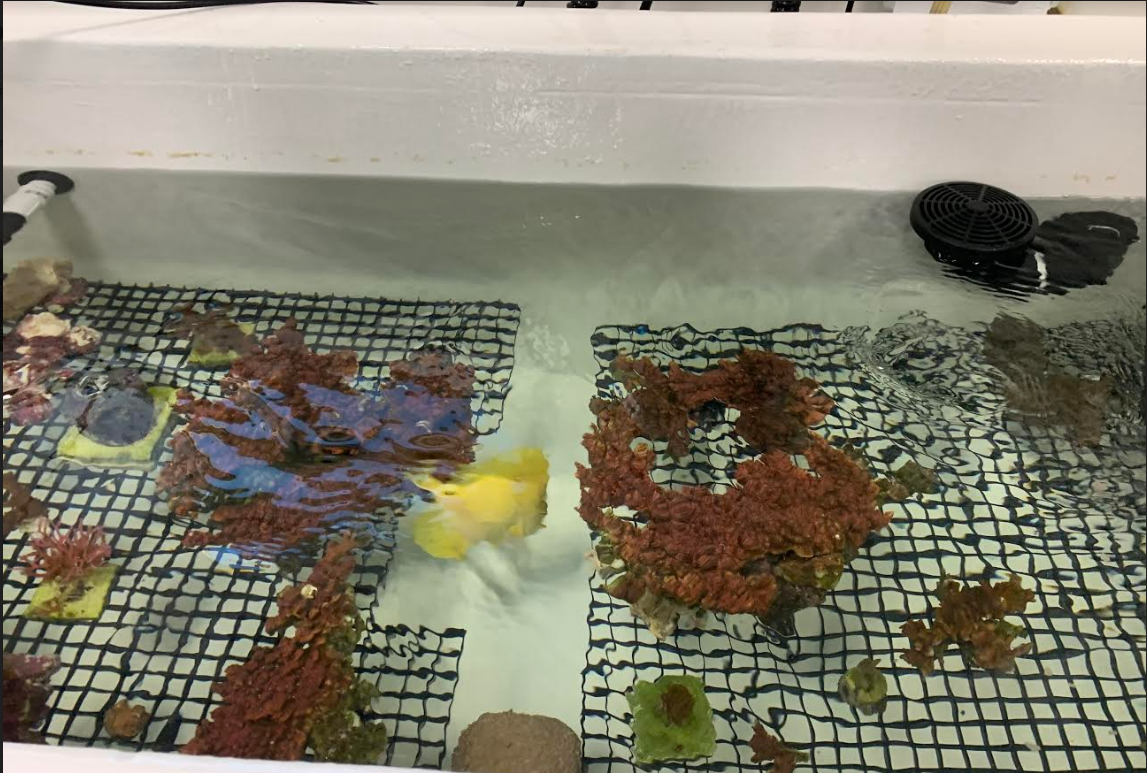

And... some coral down in the frag tanks. Everything infested with mojanos or mushrooms will left behind.

My plan is to keep the lights off in the display tank until June 1st to hopefully cut down on the ugly phase algae in the display. The frag tanks can be drained and scrubbed if things get too out of control down there. That yellow tang.... I have had for 12 years. He's a monster. I'd like to get some juvenile yellow tangs established in the main tank before I bring him up. He has killed six other yellows over the years (the last incident was 2012 or so) - but, he seems a little more mellow now. With a bigger tank, disrupted territory, hopefully, he will play nice. I have some time to think about this though.

I brought probably 70% of the live rock from the old system, no gravel. I think this will be enough to manage the nitrogen cycle with just a partial fish load.

And... some coral down in the frag tanks. Everything infested with mojanos or mushrooms will left behind.

My plan is to keep the lights off in the display tank until June 1st to hopefully cut down on the ugly phase algae in the display. The frag tanks can be drained and scrubbed if things get too out of control down there. That yellow tang.... I have had for 12 years. He's a monster. I'd like to get some juvenile yellow tangs established in the main tank before I bring him up. He has killed six other yellows over the years (the last incident was 2012 or so) - but, he seems a little more mellow now. With a bigger tank, disrupted territory, hopefully, he will play nice. I have some time to think about this though.

I brought probably 70% of the live rock from the old system, no gravel. I think this will be enough to manage the nitrogen cycle with just a partial fish load.

I got 2 months out of roll 1 and one out of roll 2. And what fun changing them is. I remove the motorized shaft with the used mat on it, that’s pretty easy if you just unscrew the 6 or whatever thumbscrews. Then the fun starts.1. I think I fixed the siphon problem by raising the pipes up just above the emergency overflow and diverting more of the flow away to the frag system. I still don't know why the flow sometimes switches from right to left and your drain box is a good idea. I have plenty of vertical space. Not sure about the blue bars, but, they did pull the sides back together by about 3 mm when I finally noticed them and installed them. Maybe support?? Gerry from Seavisions sells replacements. Maybe... i'll email him.

2. Emvanburen... how long do your CADs rolls last?

I ordered an extra shaft so I can just put it in and get the system back in operation -and then- start removing the used paper.

First time I tried cutting it off. Mess.

This time I rolled it onto the empty cardboard tube from the other side. I put them both on pvc shafts and rewound the mat. I will make some apparatus with mounted dowels or pvc to make this easier I’m the future. Maybe even use my cordless drill somehow to spin it.

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

Here is the current update... making progress but a long way to go!

I hauled my old Sante Fe Classic over from the old house, to find out that the compressor was shot. It lasted 10 years. Here is the new one... small and much quieter! I am keeping the humidity down to 50% and still tinkering with that. I'll mount this from the ceiling at some point. When I pour skimmate down the utility sink... it stinks up the whole house. Perhaps... I'll trying pouring it in the nearby toilet and turning off the constant circulation fan.

Dinos or some other brown ugly has arrived in the "frag tanks", where I am keeping my corals. No surprise. I had two big red planet colonies go down with STN... but I have two others that are looking fine. The clam has pinched mantle - we'll see if it can recover being separated 100% from fish pestering. All other corals are doing o.k. I am adding vibrant weekly, doing no algae scraping whatsoever, and waiting for the uglies to start regressing in the lower tanks.

I'll then turn the lights on in the display only after the ugly phase is over in the other parts of the system (around June 1st perhaps)... and it will be interesting to see if I can avoid an ugly phase up there or not. I don't know of anyone has taken a system intentionally through the ugly phase in one part... to see if they can avoid it in another part of the system.

I scored three yellow tangs from LA. I'd like to get them into the main tank before the big bad 10 year old yellow goes in. They all arrived with pinched bellies, but, good meat on the spine and swimming around normally. They just started picking at food today. Fingers crossed.

Here was another ordeal - getting the pressure booster to work automatically. The yellow dial with the digital meter is an electronic pressure switch. I was having trouble using a booster pump with my diayseas system (basically a combination water change and RO/DI contraption) due to the pressure difference between open and closed solenoid being only about 10 psi. I wasted about 8 hours trying to get aquatech pressure switches to work and blew out the seals on my trusty 10 year old aquatech 8800. This digital pressure switch... I got from Amazon - is awesome. It trips on just a programmed 5 psi drop. I am boosting my pressure from 59 to 80 psi. The dialyseas system... I will write up later. Still trying to get it to do what I want. It's really good at keeping the system stable. It does not keep up when I challenge it by stealing water for the QT, running super wet skimmate, etc... etc... I was trying to avoid the need for a salter water mixing station. We shall see. I have boosted the pressure to try to get some "hustle"out of the dialyseas sytem when I have stolen 5 or 10 gallons of water from the main system for something else.

I hauled my old Sante Fe Classic over from the old house, to find out that the compressor was shot. It lasted 10 years. Here is the new one... small and much quieter! I am keeping the humidity down to 50% and still tinkering with that. I'll mount this from the ceiling at some point. When I pour skimmate down the utility sink... it stinks up the whole house. Perhaps... I'll trying pouring it in the nearby toilet and turning off the constant circulation fan.

Dinos or some other brown ugly has arrived in the "frag tanks", where I am keeping my corals. No surprise. I had two big red planet colonies go down with STN... but I have two others that are looking fine. The clam has pinched mantle - we'll see if it can recover being separated 100% from fish pestering. All other corals are doing o.k. I am adding vibrant weekly, doing no algae scraping whatsoever, and waiting for the uglies to start regressing in the lower tanks.

I'll then turn the lights on in the display only after the ugly phase is over in the other parts of the system (around June 1st perhaps)... and it will be interesting to see if I can avoid an ugly phase up there or not. I don't know of anyone has taken a system intentionally through the ugly phase in one part... to see if they can avoid it in another part of the system.

I scored three yellow tangs from LA. I'd like to get them into the main tank before the big bad 10 year old yellow goes in. They all arrived with pinched bellies, but, good meat on the spine and swimming around normally. They just started picking at food today. Fingers crossed.

Here was another ordeal - getting the pressure booster to work automatically. The yellow dial with the digital meter is an electronic pressure switch. I was having trouble using a booster pump with my diayseas system (basically a combination water change and RO/DI contraption) due to the pressure difference between open and closed solenoid being only about 10 psi. I wasted about 8 hours trying to get aquatech pressure switches to work and blew out the seals on my trusty 10 year old aquatech 8800. This digital pressure switch... I got from Amazon - is awesome. It trips on just a programmed 5 psi drop. I am boosting my pressure from 59 to 80 psi. The dialyseas system... I will write up later. Still trying to get it to do what I want. It's really good at keeping the system stable. It does not keep up when I challenge it by stealing water for the QT, running super wet skimmate, etc... etc... I was trying to avoid the need for a salter water mixing station. We shall see. I have boosted the pressure to try to get some "hustle"out of the dialyseas sytem when I have stolen 5 or 10 gallons of water from the main system for something else.

Last edited:

- Joined

- Mar 30, 2020

- Messages

- 273

- Reaction score

- 622

I love your build and the ability to view the large side from both sides, the 'hidden' office on the other side is amazing. I can't wait to see the display with corals and fish in it! I'm looking forward to the writeup of your dialyseas system as well.

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

Cloudy water... begone! 5/8/2020 8:41 a.m. - UV bulb just turned on.

This haze has been persistent since I mixed up the saltwater... and it's just not quite clearing, carbon didn't work, it changes throughout the day. I suspect a bacterial bloom. I could take some water to work, centrifuge it and do microscopy on the pellet. Maybe, next week.

Below is a 150 w UV sterilizer - (I used my points for it since I won't be travelling anytime soon). I did not have a good experience with a previous UV sterilizer - due to leaking seals, failing ballasts, failing bulbs. So, I am trying a different brand this time.

One bulb, one ballast. Hygger variable speed DC pump. I can run it at slow speed 1000 gph - for protozoan kill rate. Max speed on this pump is 2650 gph... which is about half of the 6000 gph max for this UV sterilizer. That's the highest flow I can practically provide at this point. Hopefully, the flow rate will be enough to clarify the water. Once clear... I can drop the flow rate to control the protozoans in the water column.

Also shown is my skimmer which is pulling an impressive amount of REALLY smelly stuff. I am planning to call lifereef and get a 24 inch extender for it. Interesting that it is pulling MUCH more stuff compared to it's duty in the old tank... even though the livestock load is a little less and my mechanical filtration is much more robust. I was not anticipating that. If I do clear the water column of bacteria... I wonder what the skimmer will do. I'll keep pushing it for now to make lots of wet skimmate.

This haze has been persistent since I mixed up the saltwater... and it's just not quite clearing, carbon didn't work, it changes throughout the day. I suspect a bacterial bloom. I could take some water to work, centrifuge it and do microscopy on the pellet. Maybe, next week.

Below is a 150 w UV sterilizer - (I used my points for it since I won't be travelling anytime soon). I did not have a good experience with a previous UV sterilizer - due to leaking seals, failing ballasts, failing bulbs. So, I am trying a different brand this time.

One bulb, one ballast. Hygger variable speed DC pump. I can run it at slow speed 1000 gph - for protozoan kill rate. Max speed on this pump is 2650 gph... which is about half of the 6000 gph max for this UV sterilizer. That's the highest flow I can practically provide at this point. Hopefully, the flow rate will be enough to clarify the water. Once clear... I can drop the flow rate to control the protozoans in the water column.

Also shown is my skimmer which is pulling an impressive amount of REALLY smelly stuff. I am planning to call lifereef and get a 24 inch extender for it. Interesting that it is pulling MUCH more stuff compared to it's duty in the old tank... even though the livestock load is a little less and my mechanical filtration is much more robust. I was not anticipating that. If I do clear the water column of bacteria... I wonder what the skimmer will do. I'll keep pushing it for now to make lots of wet skimmate.

- Joined

- Jul 20, 2018

- Messages

- 889

- Reaction score

- 1,505

That’s awesome. What brand UV did you have issues with before? I’ve used Pentair in the past, and I’m turning on a 120w Lifegard Aquatics unit soon.

I used this one before -

The Aqua UV with wipers. My main gripe was depending on two bulbs, two ballasts and the wipers. Also, the necessity of horizontal mounting to make the wipers work - and having it hooked up to a pressure rated pump in the basement might not have been a good idea. As the unit aged... I had multiple ballast and premature bulb failures. Shipping was an issue back then, with bulbs showing up broken or not working, and once even a brand new ballast was dead - which tipped me over the edge and I threw it in the garbage. That was years ago, and with perhaps improved ballasts and a model without wipers - and maybe, a lower pressure plumbing setup.... others could get better results.

What I got this time (pentair) was most attractive to me just for being simpler - with a single ballast and bulb - less gaskets etc... Being able to mount it vertically, and not attached to the main system pump... I hope there is less pressure at the critical gaskets (I think occult water intrusion might have been what was killing my other setup) I hope it's better this time!

Similar threads

- Replies

- 24

- Views

- 730

- Replies

- 17

- Views

- 693

- Price: $50-125

- Shipping NOT Available

- Replies

- 18

- Views

- 934