Hello!

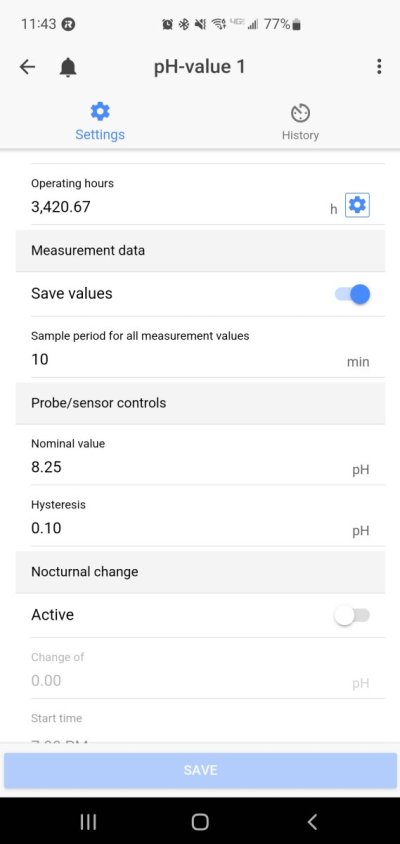

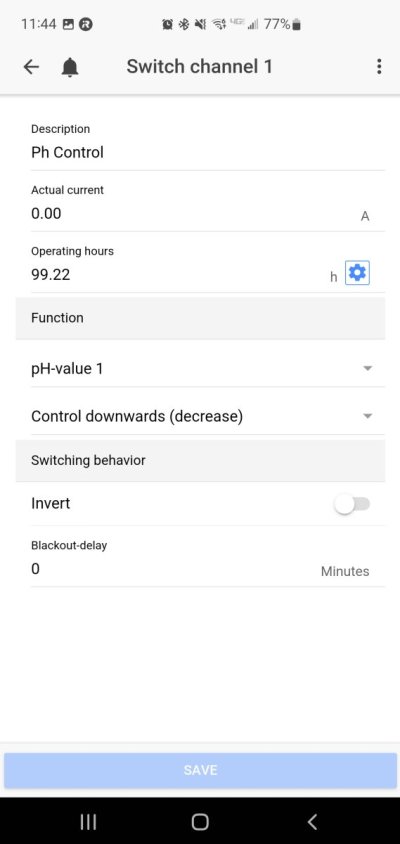

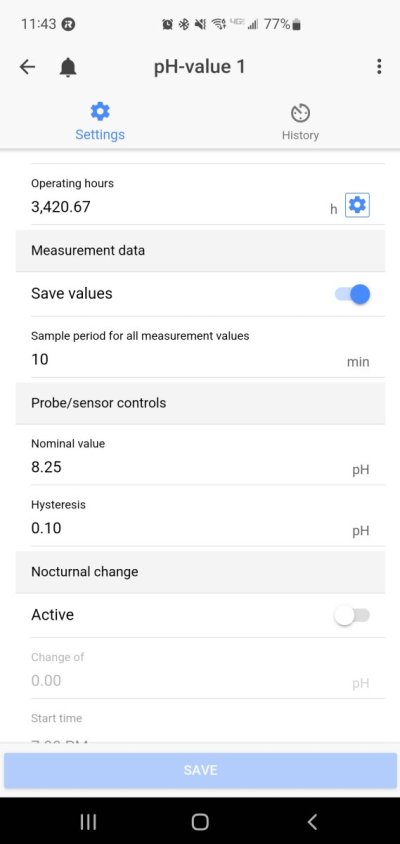

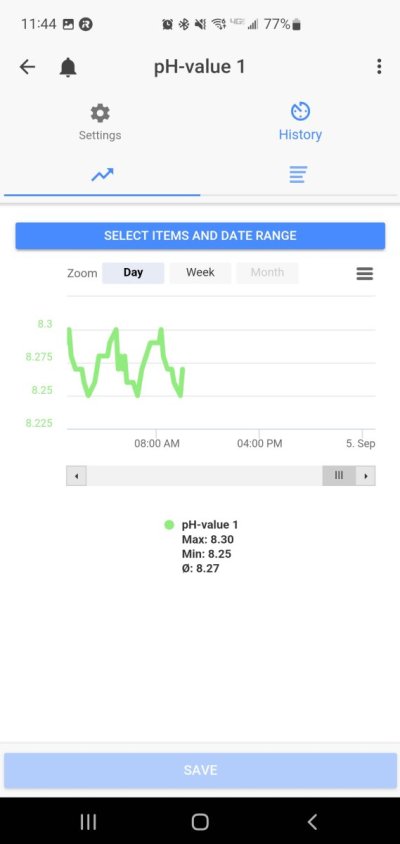

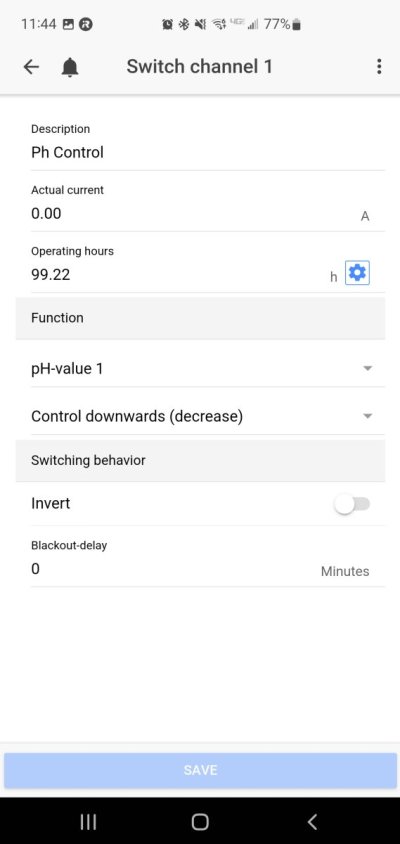

I'm using my pH probe on my PF4 to control a socket that opens and closes a valve for my CO2 scrubber. My nominal is set to 8.25 with hysteresis at 0.1 (pretty tight IMO, but I'm testing the set up as I just hooked it up last week). As I understand, this should set controlling range to 8.20-8.30. My socket that has my valve is set up to the pH probe and controlling downwards.

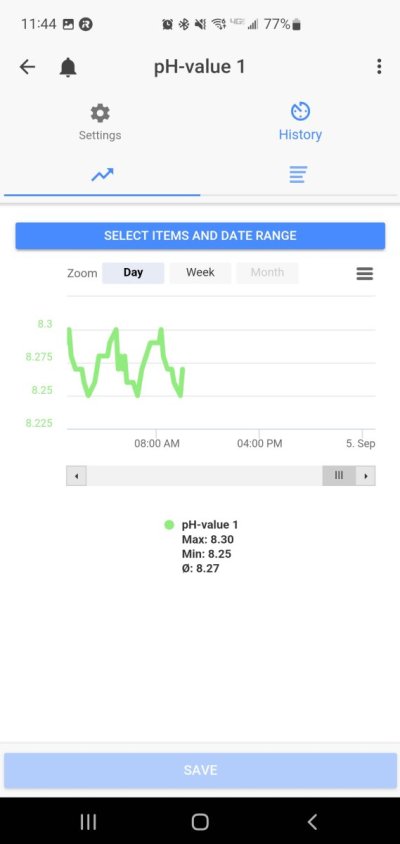

What I've witnessed is that the socket opens the valve at 8.3 to divert past the scrubber (correct action) and lower the pH. The socket closes the valve, though, at 8.25 to start increasing pH instead of at 8.20 as I thought it should. Any thoughts? Should I just reduce my nominal to 8.20?

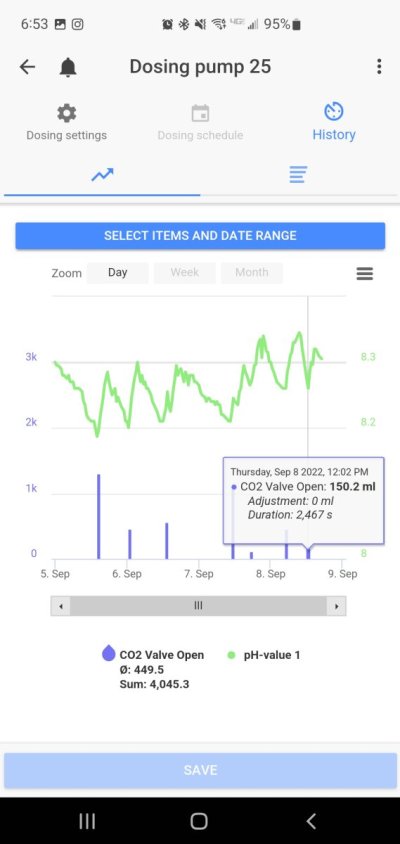

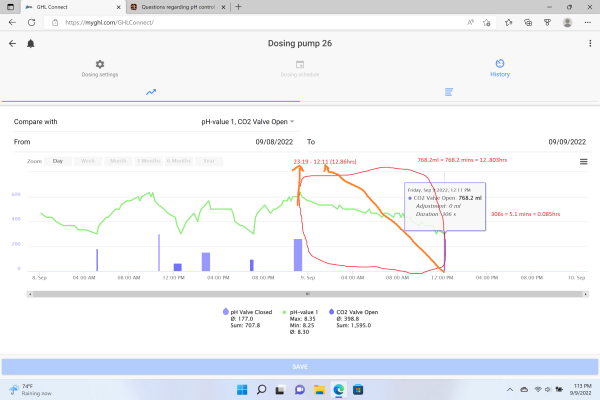

Also, I would really like to chart out the status of the socket. Besides looking at the pH chart, I don't know how often the valve is opening or closing based on the PowerBar status. It would be great to have this option so I know how much the valve is actuating. PH can be affected by many variables so a rise and fall might not be directly a result of my scrubbing. Maybe have the chart function based on change of status instead of measurement interval like the probes?

I've got some screenshots attached for the first issue.

I'm using my pH probe on my PF4 to control a socket that opens and closes a valve for my CO2 scrubber. My nominal is set to 8.25 with hysteresis at 0.1 (pretty tight IMO, but I'm testing the set up as I just hooked it up last week). As I understand, this should set controlling range to 8.20-8.30. My socket that has my valve is set up to the pH probe and controlling downwards.

What I've witnessed is that the socket opens the valve at 8.3 to divert past the scrubber (correct action) and lower the pH. The socket closes the valve, though, at 8.25 to start increasing pH instead of at 8.20 as I thought it should. Any thoughts? Should I just reduce my nominal to 8.20?

Also, I would really like to chart out the status of the socket. Besides looking at the pH chart, I don't know how often the valve is opening or closing based on the PowerBar status. It would be great to have this option so I know how much the valve is actuating. PH can be affected by many variables so a rise and fall might not be directly a result of my scrubbing. Maybe have the chart function based on change of status instead of measurement interval like the probes?

I've got some screenshots attached for the first issue.