RC75 DIY Stand and Sump

This is me through the eyes and art of my daughter.

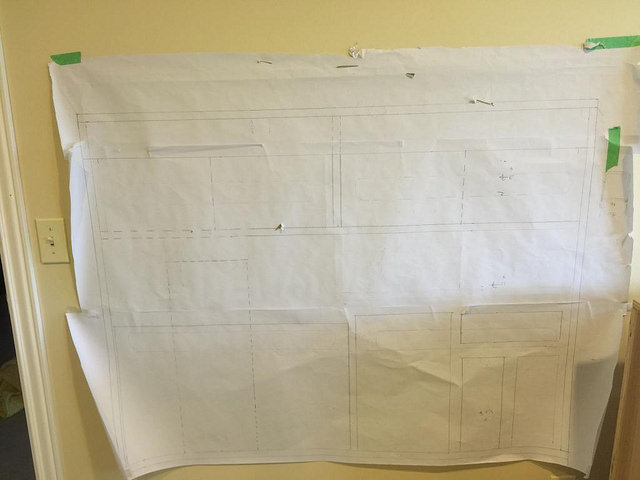

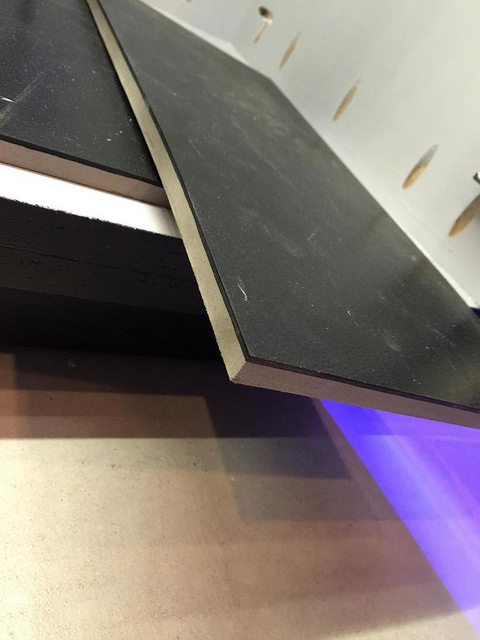

I started this build a while back, but had to let it go dormant due to circumstances. I'm starting to get back to speed. This is a 75 gallon build, highlighting a DIY stand and sump.

Started with a Great Lakes Aquariums 75G 48x18x22 with starfire glass.

Aquarium 75G 48x18x22

DIY Birch Plywood Stand 48x18x40H

Lighting Ecotech Radion Pro 3

DIY Sump 20G

DIY Sock Silencers

Skimmer Skimz Monzter SM163

Avast Marine Vibe for Zeovit

Return Pump Eheim 2400

Ecotech MP-40 & MP-10

Backup Ecotech Battery

Apex Controller & Ecotech ReefLink

Cobalt Heater

Dosing Pump GHL Profilux

This is me through the eyes and art of my daughter.

I started this build a while back, but had to let it go dormant due to circumstances. I'm starting to get back to speed. This is a 75 gallon build, highlighting a DIY stand and sump.

Started with a Great Lakes Aquariums 75G 48x18x22 with starfire glass.

Aquarium 75G 48x18x22

DIY Birch Plywood Stand 48x18x40H

Lighting Ecotech Radion Pro 3

DIY Sump 20G

DIY Sock Silencers

Skimmer Skimz Monzter SM163

Avast Marine Vibe for Zeovit

Return Pump Eheim 2400

Ecotech MP-40 & MP-10

Backup Ecotech Battery

Apex Controller & Ecotech ReefLink

Cobalt Heater

Dosing Pump GHL Profilux