Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

show me your DIY plywood stands

- Thread starter Devaji

- Start date

- Tagged users None

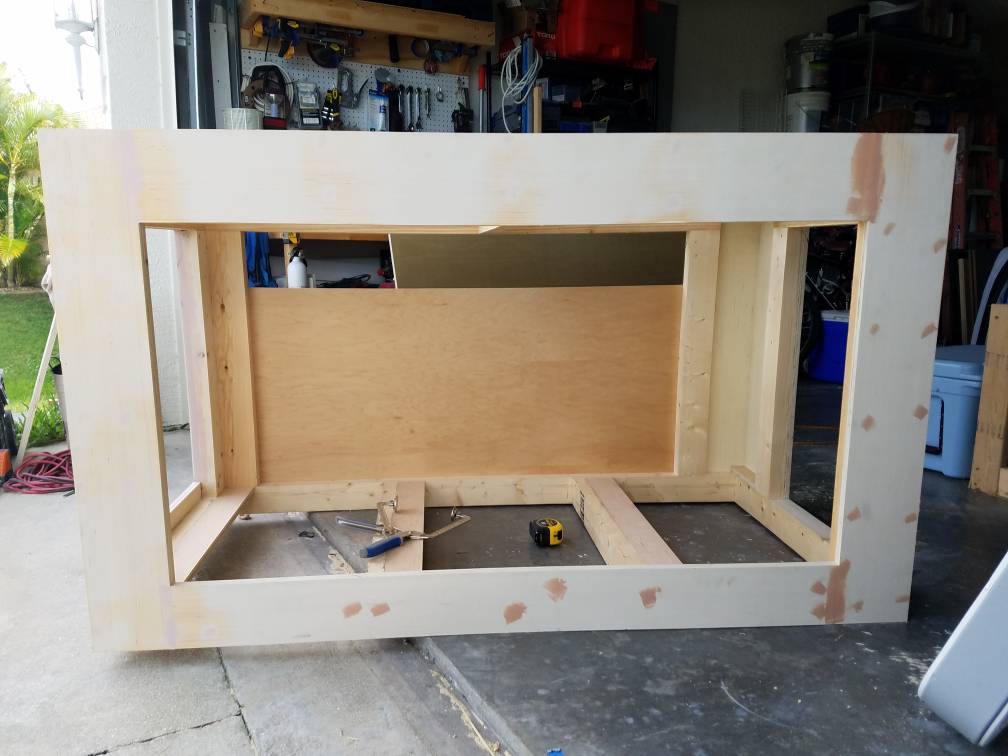

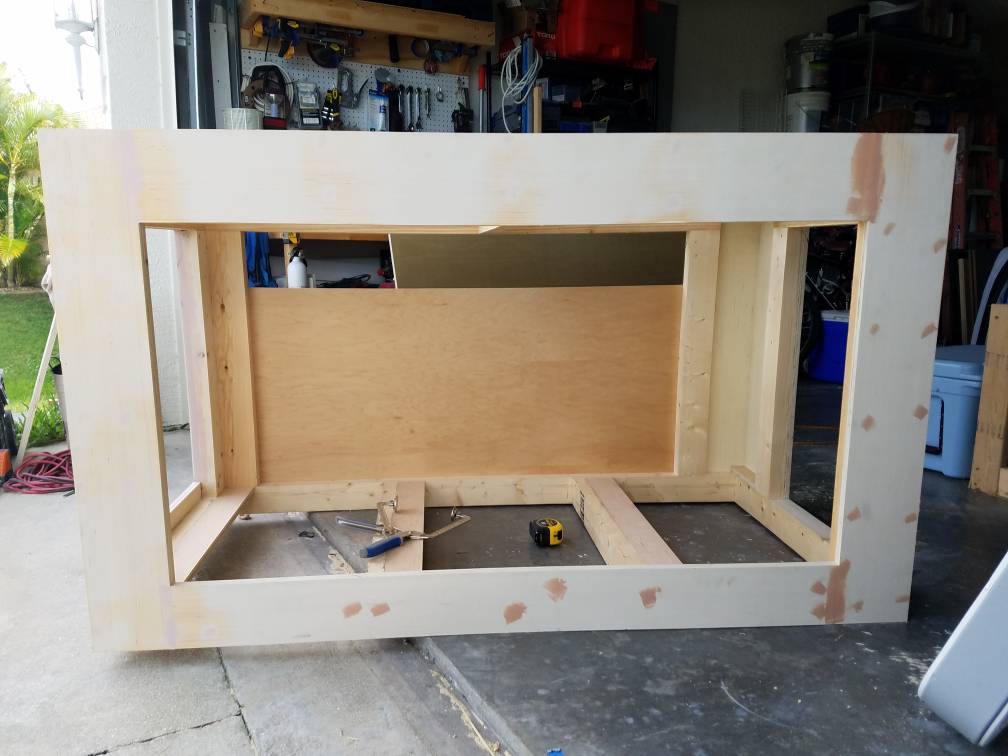

Getting closer...

Looking good!

Pocket screws are useful for securing boards edge to edge. When building a wooden box, there is little call for this. Oh, I suppose you could use pocket screws to join the styles and rails where you're going to put the door, but for the most part, you're going to be joining boards at a 45 degree angle. There are several methods...

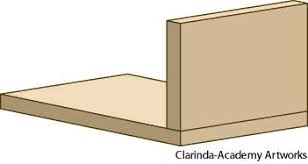

A butt joint, where both ply parts are square cut, the edge of one glued to the face of the other. Two problems... it's not particularly strong, and you end up with one ply edge exposed, which doesn't look very good. You can, however easily use plain wood screws to help strengthen the joint.

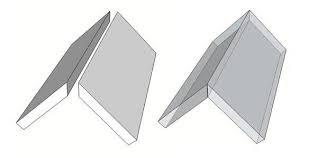

A miter joint, where both ply parts are cut to 45 degrees, and glued together. Still not particularly strong, edge to edge, but it works. If you can use a square glue block inside the joint, it'll strengthen it quite a bit. no edge grain to deal with, anyway.

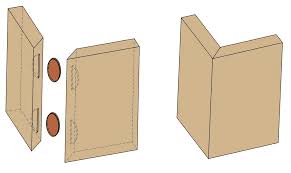

Biscuit joint, this would be my choice, but you've got to have a biscuit cutter. Biscuits reinforce the joint from the inside, quite strong, and easy, if you've got the tools.

Spline joint, a bit harder, but you can do it with a normal table saw. Cut to 45 degrees, and then reverse cut to accept a thin spline. Quite strong.

What I did with my stand was use solid poplar corners, and cut a chanel (dado) into each to accept the ply, so that the ply was in contact on 3 sides all across the joint. Strong, simple, and gives you a nice finished look.

would not adding pocket screws to a but joint made it stronger?

Yes, pocket screws will increase the strength of the joint. If you use a jig like the Kreg jig, the issues around hole depth and screws protruding through the surface are automatically dealt with and it is very quick and easy. There's probably no difference between using pocket screws and plain wood screws screwed in from the back side as far as strength is concerned. The big difference is where they're visible.

As Greybeard pointed out, the big problem with plywood is the edges. Butt joints are easier, but they leave the edges exposed. cutting the edges at a 45º angle solves that problem but creates a problem in finding a strong joinery method. I honestly can't say what the strongest joint is for this application. The problem with plywood is that things like splines and biscuits have much less grain area to adhere to. Fortunately, the main concern is sheering, so any of these methods will likely work fine.

If you have a router, you can get a biscuit cutting bit for it and use that to either cut biscuit or spline slots. If you're cutting on a 45º angle, then using a table saw and splines is probably the easiest option. Adding a face frame is another good way to cover up the end grain and add some strength.

This is a great thread. The default seems to be using 2x4's with something like rocketman's design. That works, but is horribly overbuilt and wastes a lot of space. Plywood is more than strong enough (builders can tell you how strong microlam beams are,) and actually makes better use of resources. On top of that, finding straight & true 2x4's at most home centers is more than a challenge.

dang those are nice guys!

even futher can I see inside? got pics of the build in progress?

Dlech59 wow thats some nice work wish I have some cherry and wallnut laying around. looks sharp!

Same here! I wish I had high quality wood laying around. Even if I did though nothing I’m capable of would turn out like that, Looks amazing.

- Joined

- Jul 1, 2018

- Messages

- 46

- Reaction score

- 38

Just finished stand for my 120 gallon tank. Working on my canopy now

Finally got the door attached... a single piece of 3/4” birch plywood with plywood edging veneer attached with French cleats so that the whole panel is removable for better access to the sump. Now just have to attach the back wall, rear corner trim, prime and paint!

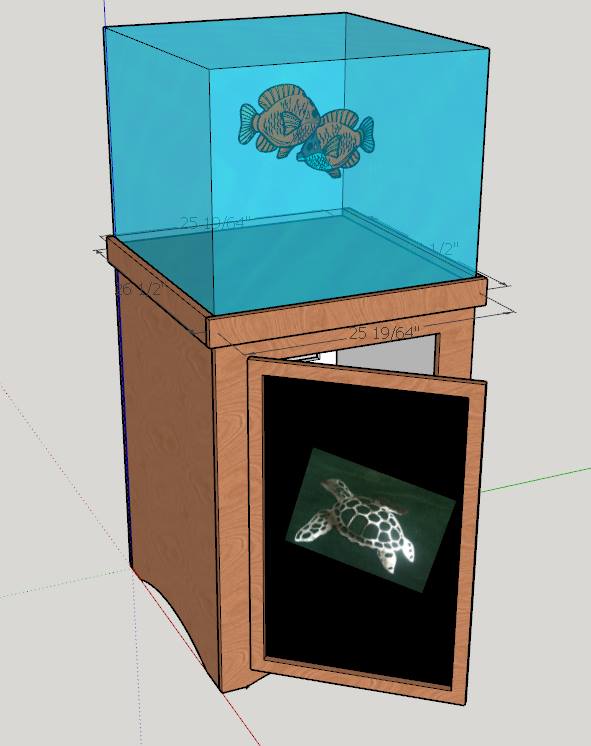

That’s nice.Drew this up a couple of weeks ago in Sketchup. This is for a IM Nuvo 40 cube.

In progress last weekend...

Finished

Inside painted with high gloss enamel to reflect light and make for an easy cleanup.

Filled it last night, looking good this morning.

Box is made from 3/4" Oak ply with some oak trim applied across the top and down the sides to cover the edges of the plywood. I also used oak banding strips to cover the edge facing inside the door and the back cut out.

Here are some stands I've built over the past 4 months or so.

A triple 200 gallon coral system for a lfs

Also working on the fish system in the back

A 150 peninsula build for a forum member

And my elos 160xl stand

Lol I hope to not have to build to many more this year I need a break!

A triple 200 gallon coral system for a lfs

Also working on the fish system in the back

A 150 peninsula build for a forum member

And my elos 160xl stand

Lol I hope to not have to build to many more this year I need a break!

@Fishinbob those are amazing stands although the intention of the thread was all plywood no 2x4 2x6 etc. but man those are nice.

question what did you skin that last stand with? laminate sheet?

question what did you skin that last stand with? laminate sheet?

My bad buddy.... lol I always end up building larger stands and I always reccomend no center brace hence the 2x. I used a high gloss wilsonart laminate. Difficult to apply but looks sharp! Let me see if I have some of my older ply stands!@Fishinbob those are amazing stands although the intention of the thread was all plywood no 2x4 2x6 etc. but man those are nice.

question what did you skin that last stand with? laminate sheet?

My bad buddy.... lol I always end up building larger stands and I always reccomend no center brace hence the 2x. I used a high gloss wilsonart laminate. Difficult to apply but looks sharp! Let me see if I have some of my older ply stands!

oh no worries at all. as we all love see the handy work of ppl building. so thanks for jumping on board.

yeah I bet that is hard to apply. I was thinking of redoing my 2x4 stand with an all plywood stand for my 90 but decided to not bother.. for now anyway...but I was thinking of doing the laminate.

can you share more pic of the process and the result looks amazing!!

Nice stand @Fishinbob! Where is mine!?

I think I need to pick your brain a little for a project I had in mind.

I think I need to pick your brain a little for a project I had in mind.

- Joined

- Apr 3, 2017

- Messages

- 2,471

- Reaction score

- 3,403

I'm going to be building a new stand for a sca 150 soon and was wondering how much weight your stands are capable of holding without a center brace? I love the clean look of your stands but am terrified of not having a center brace..My bad buddy.... lol I always end up building larger stands and I always reccomend no center brace hence the 2x. I used a high gloss wilsonart laminate. Difficult to apply but looks sharp! Let me see if I have some of my older ply stands!

I cant speak for @Fishinbob but by the looks of it I believe you would be more than OK. looks like he build quality stuff there.

the SCA 150 is a 5' tank I bet he would still use 2x6 for the length...but then again what the heck do i know so I will just carry on...lol

the SCA 150 is a 5' tank I bet he would still use 2x6 for the length...but then again what the heck do i know so I will just carry on...lol

- Joined

- Apr 3, 2017

- Messages

- 2,471

- Reaction score

- 3,403

Lol!

Hey fishybizzness, the raw wood stand in the pictures above was for a SCA 150 penninsula. I used a 2 x 6 beam for the top plate anything over 48 in I used two by sixes 4ft tanks I used two by fours. I would say these stands are rated about three or four times the actual weight of tank water sand and rock. They are extremely overbuilt. On my 90 gallon I have a 4 inch ledge around the perimeter of the tank that I walk on when placing rocks and corals need be without hesitation and I'm a big guy. The original rocket engineer design is tried-and-true and excessive Imo. The stand usually weigh about as much as the tank once completeI'm going to be building a new stand for a sca 150 soon and was wondering how much weight your stands are capable of holding without a center brace? I love the clean look of your stands but am terrified of not having a center brace..

Antics, just saw your message I'll p.m. you shortly!Nice stand @Fishinbob! Where is mine!? [emoji14]

I think I need to pick your brain a little for a project I had in mind.

Similar threads

- Replies

- 1

- Views

- 147