- Joined

- Jun 27, 2020

- Messages

- 38

- Reaction score

- 7

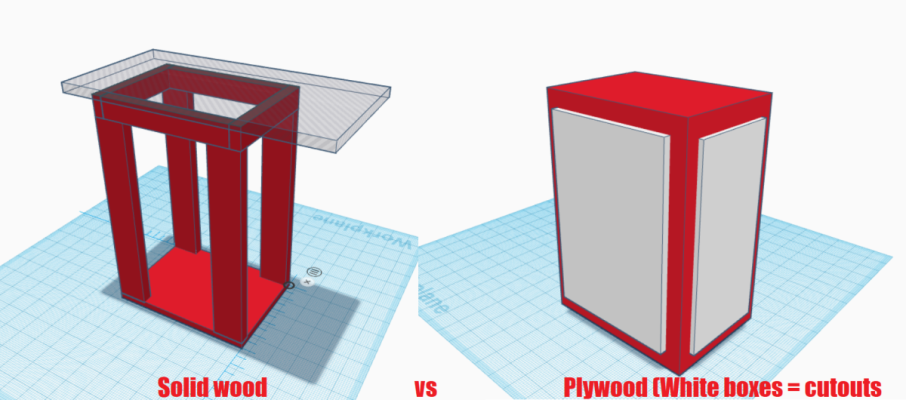

Let's say i wanna build open frame stand for my aquarium.

I have option of using the following for each corner leg. Which leg would be better/stronger? (Tank size is ~35 gallon tall.)

2x4" solid pine log/planks.

VS

1.5x5" plywood strips at corners connected with screws/bracket, making "L" shape leg. (4 sheets having middle cut out like "window", then screwed together like a box.)

Leg length would be ~40"

I think simple 2x4" would be stronger?

I have option of using the following for each corner leg. Which leg would be better/stronger? (Tank size is ~35 gallon tall.)

2x4" solid pine log/planks.

VS

1.5x5" plywood strips at corners connected with screws/bracket, making "L" shape leg. (4 sheets having middle cut out like "window", then screwed together like a box.)

Leg length would be ~40"

I think simple 2x4" would be stronger?