Hi,

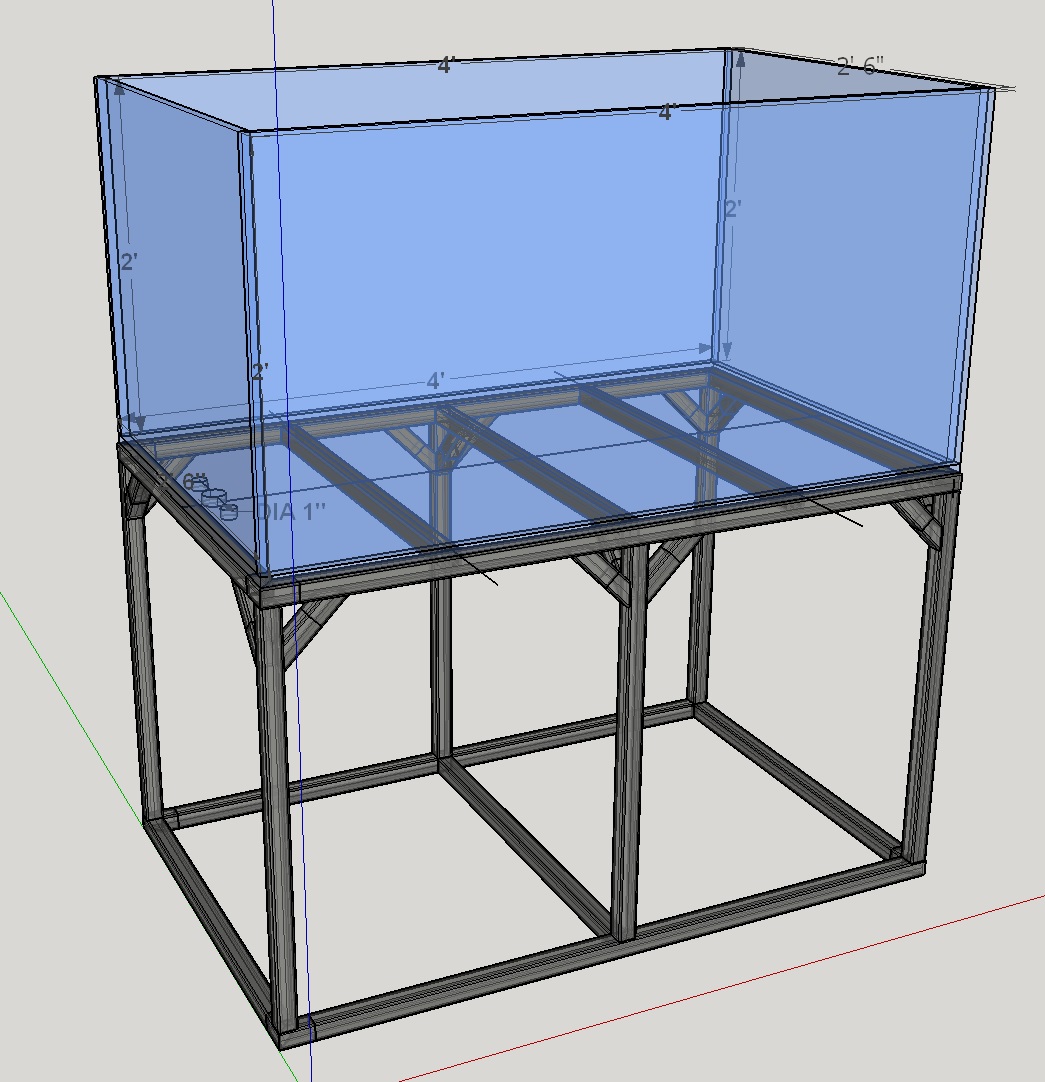

I have a 150 gallon glass rimless peninsula that I will be building my first steel stand for. The tank is a 48" x 24" x 30" with 5/8" glass. It's a rimless with small diagonal braces up top, which I plan on adding additional eurobracing to. I live in San Diego and the tank will be on top of tile flooring with a concrete slab under it.

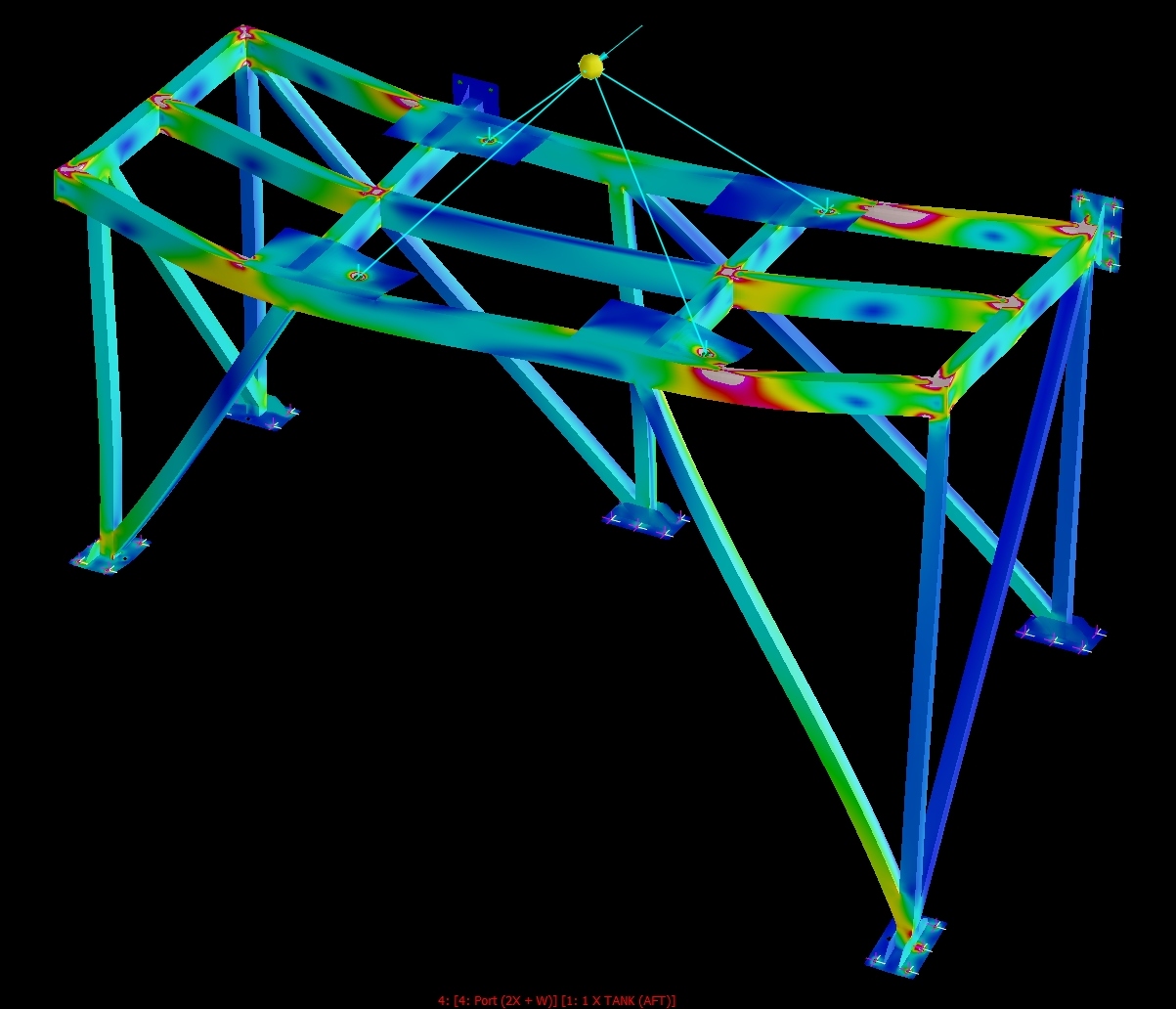

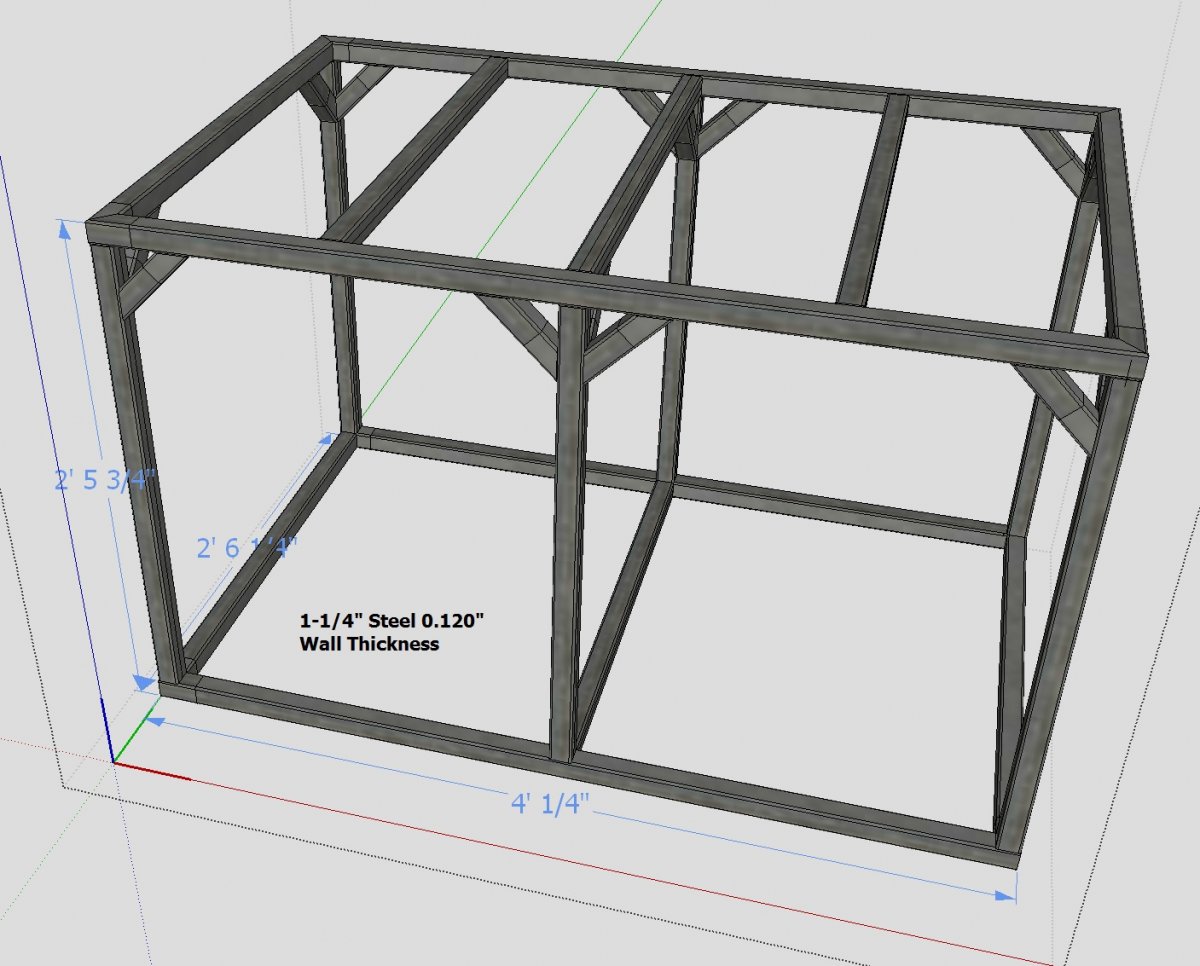

I came up with a basic layout for the stand which I plan to make with some 1.25" x 1.25" .120" wall thickness square tubing that I have laying around in the house. My welder friend says the design should be more than adequate for the tank, but if possible, I would love to get an engineer's input here.

If i HAVE to use 2" x 2" or greater, I guess I could, but since I have around 100' of the 1.25" laying around, I would prefer to use this.

Any inputs, feed backs and/or criticisms would be much appreciated. Thank you.

I have a 150 gallon glass rimless peninsula that I will be building my first steel stand for. The tank is a 48" x 24" x 30" with 5/8" glass. It's a rimless with small diagonal braces up top, which I plan on adding additional eurobracing to. I live in San Diego and the tank will be on top of tile flooring with a concrete slab under it.

I came up with a basic layout for the stand which I plan to make with some 1.25" x 1.25" .120" wall thickness square tubing that I have laying around in the house. My welder friend says the design should be more than adequate for the tank, but if possible, I would love to get an engineer's input here.

If i HAVE to use 2" x 2" or greater, I guess I could, but since I have around 100' of the 1.25" laying around, I would prefer to use this.

Any inputs, feed backs and/or criticisms would be much appreciated. Thank you.