Not sure what you mean by bowing. Rocket Engineer has made it clear (since 20080.018"

But at this point I personally start to consider the "legs" and bowing..

Should be fine though.

Different subject just for reference:

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Structural engineers: Please HELP with 7 foot DIY stand build.

- Thread starter mjovic

- Start date

- Tagged users None

- Joined

- Sep 18, 2017

- Messages

- 5,605

- Reaction score

- 3,450

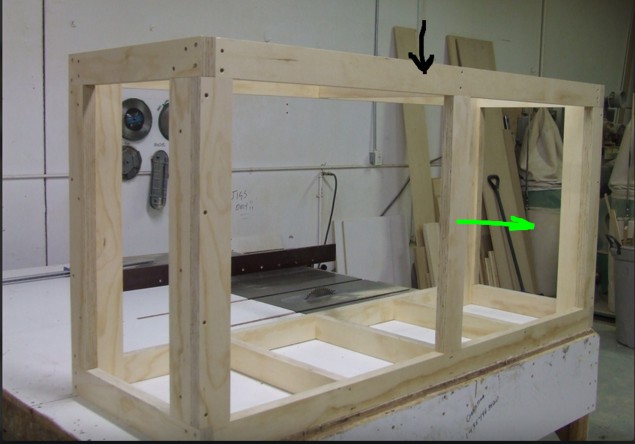

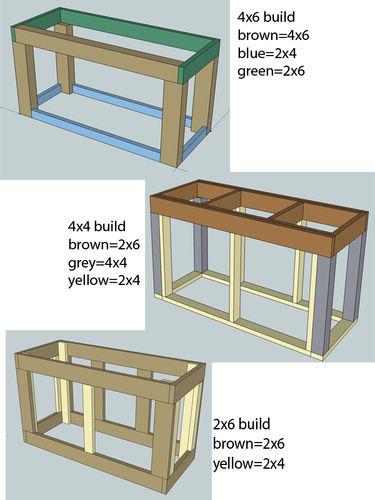

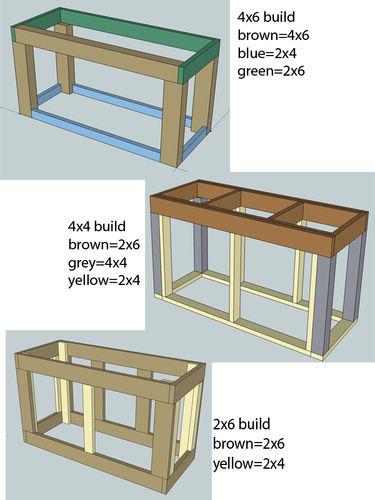

Yea just my paranoia.. I didn't think it was an issue.Not sure what you mean by bowing. Rocket Engineer has made it clear (since 2008) that no matter what size of stand is built, 2x4's are sufficient support for the weight (and that by a huge margin...think 10,000+ lbs. per leg.) The only real question is in the height of the top rails 2x4, 2x6, 2x8 etc. and deflection over a given span as well as the ability to prevent the stand from wracking. Honestly, as much as I would like a 7' open bottom stand, for my application because I am limited to a 34" high stand I might need to just go with 2x4 all around and deal with the 2 supports in front of the sump. I think 2x8 will eat up too much valuable space and limit my sump options. :-(

What pops in my mind..using the plywood one. I don't know the ACTUAL physics here..

It's not the dead load down per se...

The corners are err "boxed" so not an issue. I could assume the 2x4 will be braced to avoid any "twist".

What about the 2x6 54" span one?

Last edited:

After reading through 230+ pages of DIY stand builds (on another forum) dating back to 2008 I have yet to hear of that happening to anyone and hundreds of stands have been built using ONLY 2x4's as supports as they are wicked strong. As long as the stand is level and true (top surface totally planar) then all the weight will be equally distributed (along the rails on a framed tank and all across the top plywood and cross beams in a rimless or acrylic tank) to the legs wich have enormous compressive strengths. Deflection and wracking remain the top concerns. Since I plan to skin 3 sides, the top and bottom in plywood I am not concerned with wracking. The 2x6 option could work, but I am trading off 2" of height for not having a second rail. If I stick with a 4' sump then I might go that direction, but I starting think I need to go larger on the sump to better handle the flow I'll have on the main tank. If I do end up going larger then it would be a 5 foot or 6 foot sump in which case I'd have a leg in the way anyway so....decisions decisions! Hah.Yea just my paranoia.. I didn't think it was an issue.

What pops in my mind..using the plywood one. I don't know the ACTUAL physics here..

The corners are err "boxed" so not an issue.

What about the 2x6 54" span one?

- Joined

- Sep 18, 2017

- Messages

- 5,605

- Reaction score

- 3,450

Like I said it is "just me" and my own thoughts, right or wrong. But when one "helps" someone it would a disservice not to disclose ALL thinking.

Besides this is a huge tank and as such requires full due diligence..

And if cased in 3/4 plywood (common) the issue goes away on 3 sides..

www.lumberjocks.com

www.lumberjocks.com

As to the 100's built well as someone who's remodeled/repaired old homes there are things I've seen that work that technically shouldn't.

Besides this is a huge tank and as such requires full due diligence..

And if cased in 3/4 plywood (common) the issue goes away on 3 sides..

aquarium stand strength

As to the 100's built well as someone who's remodeled/repaired old homes there are things I've seen that work that technically shouldn't.

I hear you! That's why I read through 230 pages and still have questions and cold feet! @RocketEngineer can you chime in and give your $.02? Will the above design on post #59 work? Any issues? OK to go with 2x4 top rail or do I absolutely need a 2x6 with my tank size?Like I said it is "just me" and my own thoughts, right or wrong. But when one "helps" someone it would a disservice not to disclose ALL thinking.

Besides this is a huge tank and as such requires full due diligence..

And if cased in 3/4 plywood (common) the issue goes away on 3 sides..

aquarium stand strength

www.lumberjocks.com

As to the 100's built well as someone who's remodeled/repaired old homes there are things I've seen that work that technically shouldn't.

Last edited:

If you add a layer of OSB or plywood BETWEEN your 2x6 header doubled up, you should be just fine at your full span. My 1000 tank is built like this, using triple 2x8 with OSB sandwiched in between with glue and screws and 10" lag through bolts. We used 4x4 legs wrapped with 2x6 and 2x8 again glued and screwed and then skinned left right top and back with 3/4" plywood. We also skinned the front with 3/4" plywood and I cut the openings for the stand in that, so basically I have a one piece frame of 3/4" ply on the front also which add to your deflection calculations. I also have a 18" bar top cantilevered out from the tank that was added onto it at a later time. Been 14 years and it has not moved at all no deflection or racking. When in doubt go bigger. It's a pain getting a huge sump in a stand sometimes. My new sump was built in 2 separate pieces and has 2 4" PVC x12" with unions to put it together and have 1 sump...sometimes you got to be smarter then the stand....hope that helps

Holy engineered stand! Sounds amazing. I agree I'd rather over do it and not have to worry for 20 years than be worried at all about deflection creep over time. While it seems a 2x6 sandwiching a 3/4" ply would be stronger than a single 2x8, the question is by how much? What was great about RE's calculations was that it was consistent and known. I'd rather not guess as to if it would be enough which has me erroring on the side of just going straight 2x4's and minimizing the spans to 24" all around. I'm pretty sure that'll work, just not sure about the top 2x4" rail being sufficient.If you add a layer of OSB or plywood BETWEEN your 2x6 header doubled up, you should be just fine at your full span. My 1000 tank is built like this, using triple 2x8 with OSB sandwiched in between with glue and screws and 10" lag through bolts. We used 4x4 legs wrapped with 2x6 and 2x8 again glued and screwed and then skinned left right top and back with 3/4" plywood. We also skinned the front with 3/4" plywood and I cut the openings for the stand in that, so basically I have a one piece frame of 3/4" ply on the front also which add to your deflection calculations. I also have a 18" bar top cantilevered out from the tank that was added onto it at a later time. Been 14 years and it has not moved at all no deflection or racking. When in doubt go bigger. It's a pain getting a huge sump in a stand sometimes. My new sump was built in 2 separate pieces and has 2 4" PVC x12" with unions to put it together and have 1 sump...sometimes you got to be smarter then the stand....hope that helps

Regarding the sump I was toying around with doing a split sump out of 2 40g breeders I have which I still might do. It's one option I'm considering.

Are there any engineered wood beams out there I could use for just the front span? 2x6"? Even if it's a little pricier I would only need it for the front. But then again I would be guessing on its strength and if it would hold. Ugh. I should have been an engineer instead of going into advertising. LOL.

LVL would be more than strong enough and there is known calculations for them. I could do the calculations on the 2x6 with osb but I'm tired tonight. Lol. Go with a double lvl ...way overkill there...good luck!

LVL would be more than strong enough and there is known calculations for them. I could do the calculations on the 2x6 with osb but I'm tired tonight. Lol. Go with a double lvl ...way overkill there...good luck!

1-3/4" x 11-7/8" x 8' LVL 1.9E

Laminated veneer lumber (LVL) is used for headers and beams when strength is important. The surface sealer color may vary from sample shown.

This stuff?

If I bought one I could rip it down the middle and have 2 2x6's. Would love to get a calculation on going for 74" opening.

- Joined

- Jul 16, 2009

- Messages

- 3,205

- Reaction score

- 4,844

LVL would be more than strong enough and there is known calculations for them. I could do the calculations on the 2x6 with osb but I'm tired tonight. Lol. Go with a double lvl ...way overkill there...good luck!

Strong yes - but prone to swelling if they get wet. I would suggest against their use as structural members under an aquarium for that reason.

I do understand that you have used them with success. I just like to plan for the worst when it comes to stand design and water damage.

Strong yes - but prone to swelling if they get wet. I would suggest against their use as structural members under an aquarium for that reason.

I do understand that you have used them with success. I just like to plan for the worst when it comes to stand design and water damage.

Aha there is always a catch isn't there? I do plan on priming and painting the entire stand inside and out and could use some polyurethane to seal it as well, but should I just avoid?

- Joined

- Jul 16, 2009

- Messages

- 3,205

- Reaction score

- 4,844

Not sure what you mean by bowing. Rocket Engineer has made it clear (since 2008) that no matter what size of stand is built, 2x4's are sufficient support for the weight (and that by a huge margin...think 10,000+ lbs. per leg.) The only real question is in the height of the top rails 2x4, 2x6, 2x8 etc. and deflection over a given span as well as the ability to prevent the stand from wracking. Honestly, as much as I would like a 7' open bottom stand, for my application because I am limited to a 34" high stand I might need to just go with 2x4 all around and deal with the 2 supports in front of the sump. I think 2x8 will eat up too much valuable space and limit my sump options. :-(

Don't confuse the compressive strength with the resistance to bowing. Yes, the vertical 2x4 is plenty strong enough in compression, but the taller the leg, the more prone it is to twisting or bowing when presented with non vertical forces.

So the 2x4 legs needs to have a skin or other bracing to prevent those twisting or deflecting forces from deforming the legs in directions aside from compression.

- Joined

- Jul 16, 2009

- Messages

- 3,205

- Reaction score

- 4,844

There are numerous ways to tackle this with different materials and designs.Aha there is always a catch isn't there? I do plan on priming and painting the entire stand inside and out and could use some polyurethane to seal it as well, but should I just avoid?

Forgive, I did not read all of the pages. Is there are budget constraint? A time constraint?

Tank will be shipped in 3 weeks. I could ask them to delay shipment if needed. Budget is in the sub $1k range. I would ideally love to have a steel stand but it would need to be created in such a way that I can assemble it in my basement as the stand wouldn't clear the turn down my stairs.There are numerous ways to tackle this with different materials and designs.

Forgive, I did not read all of the pages. Is there are budget constraint? A time constraint?

Nothing more than a bit of inspiration..

Oh yes I have watched that video probably 10x in the past year. Haha.

- Joined

- Jul 16, 2009

- Messages

- 3,205

- Reaction score

- 4,844

That is perfectly doable and may be the easiest when all is said and done.Tank will be shipped in 3 weeks. I could ask them to delay shipment if needed. Budget is in the sub $1k range. I would ideally love to have a steel stand but it would need to be created in such a way that I can assemble it in my basement as the stand wouldn't clear the turn down my stairs.

The top frame and maybe bottom frame would each be one piece with welded corner brackets to accept bolt on legs. Assemble in place.

It could also be moved in in pieces and finish welded in place.

- Joined

- Jan 12, 2020

- Messages

- 30

- Reaction score

- 9

Good input here. Use wood resting on wood with fasteners used only to prevent shifting or for marrying beams together. Use Douglas Fir 2x6 beams for extra strength. Double beams should be fine but being an engineer, I would go for triple. Is the plywood underneath to block the light through the tank? I have always had glass tanks and the bottom is designed to support the water weight with underneath support only around the edges.

- Joined

- Jul 16, 2009

- Messages

- 3,205

- Reaction score

- 4,844

Nothing more than a bit of inspiration..

Absolutely not a bad design at all... In fact very good.

I would likely use stainless screws.

The cross supports are free floating and likely and while likely more than strong enough (too lazy do do the math), as the wood shrinks, the butt screws are holding a fair portion of the distributed load. Joist hangers would be one alternative as would 2x4 cross members (butt screwed) with a 2x4 ledger would also work.

Safety factor is very important and he is correct in apply that level of margin. Even a very small tremor, shifting foundation or other even can create tremendous forces with that much suspended potential energy.

Similar threads

- Replies

- 24

- Views

- 754