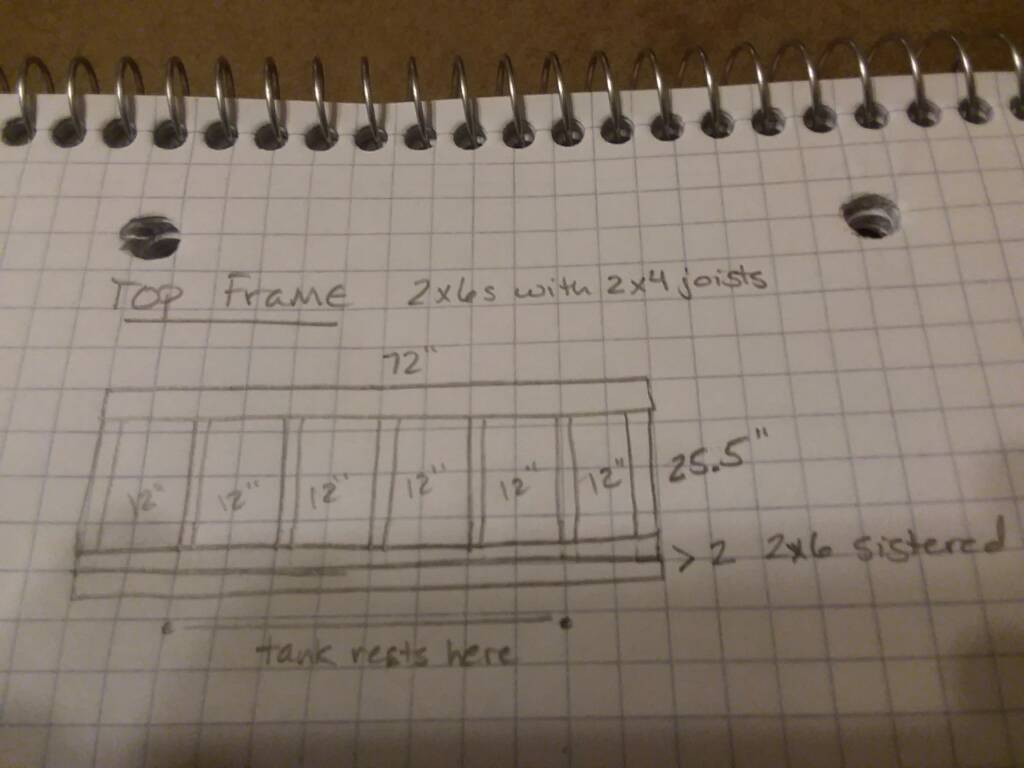

Experienced wood-working friend and I started building my stand today! YAAAY! But we hit a snag on the design and have stopped for now until I figure out what I want to do. You see, originally, I was going to sister two 2x6s on the front length of the top frame- the idea was for extra reinforcement, since the front of the tank will be sitting back a few inches and won't actually be resting on the front edge of the frame. It will have direct support under both side edges and back edge, though, and there will be a sheet of plywood between tank and stand, so it ought to be fine. As buddy and I were considering the best way to add supports, he asked if the extra 2x6 in the front is even necessary. Oh, god, is it even necessary?? If I've got a top 2x6 frame, and it's properly supported on its corners with a center brace in front, and there's going to be plywood across the top, do I really need that extra reinforcement? Can I just add the missing vertical supports and be done with it?

For those who've missed my previous threads about this, the tank is going to be 4x2x2' on a stand 6' long, 36" tall, and either 28" or 28.5" front-to-back (28" as it stands now, 29.5" if I add that second 2x6). I'm building the stand bigger than the tank because I want maximum room underneath to work in, and so that if/when I upgrade, I've already got a stand with a 72 x 28" footprint for a bigger tank. A pic of the original sketched plan, and some pics of the stand as it is today are below. Oh, and I WILL be putting in 2x4s vertically on the corners between the top and bottom frames! I'm not going to leave it as is! There's also going to be a center brace in the middle on the front and two in the back (under the edges of the tank). What I'm asking about is sistering the 2x6 on the front of the top frame.

Am I making any sense? I hope so!

For those who've missed my previous threads about this, the tank is going to be 4x2x2' on a stand 6' long, 36" tall, and either 28" or 28.5" front-to-back (28" as it stands now, 29.5" if I add that second 2x6). I'm building the stand bigger than the tank because I want maximum room underneath to work in, and so that if/when I upgrade, I've already got a stand with a 72 x 28" footprint for a bigger tank. A pic of the original sketched plan, and some pics of the stand as it is today are below. Oh, and I WILL be putting in 2x4s vertically on the corners between the top and bottom frames! I'm not going to leave it as is! There's also going to be a center brace in the middle on the front and two in the back (under the edges of the tank). What I'm asking about is sistering the 2x6 on the front of the top frame.

Am I making any sense? I hope so!