I'd like to make one of these, can you post part names/#'s? Anymore pics of the internals?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tunze Powerhead Rotator

- Thread starter hollback

- Start date

- Tagged users None

hollback, where did you get the speed control from?

I had to put one together based on the motor and power specs I needed. Just make sure it is a "PWM speed control." Google should help explain the types of speed controls and how to construct them.

There is a few threads around describing how to build one, look up swirl Stein. I am in the process right now, but using a AC microwave motor.

There is a few threads around describing how to build one, look up swirl Stein. I am in the process right now, but using a AC microwave motor.

I don't think the Swirl Stein would handle the pulsing of a Tunze 6105 very well. These seem to be built for something constantly running like a maxi jet.

I don't think the Swirl Stein would handle the pulsing of a Tunze 6105 very well. These seem to be built for something constantly running like a maxi jet.

Yea i am not sure. People did use them with tunzes, but not sure if they were controlled are not. Yours is basically the same principle though.

Cool Idea!

Yea i am not sure. People did use them with tunzes, but not sure if they were controlled are not. Yours is basically the same principle though.

Yeah, not a new idea, just a different way of doing it. No matter what does it, a rotating powerhead is much more efficient than a stationary one!

Nice. Got to dig through all my pics. Will post the drive I invented, I use it for the Reef-Rat, Super-Rat, Tunze-Rat and the Seio-Rat. Basically all the same thing.

Last edited:

For a start, try to get a 24vac motor from a manufacturer such as Hansen Corp. One rpm should be good and the 24vac power supply can be obtained at almost any surplus electrical supply store. If I remember right they're called PMAC Syncron. The box with the part number is behind the dirt bikes stored away for the winter...lol.

The advantage to using a 24vac motor, is it's low voltage and will not cause any major catastrophe if ever the unit would get submerged or doused.

Also you won't get any voltage leaks into your tank due to bad grounding. My understanding is, that anything under 30vac, does not require UL/CSA testing due to it's inherent low voltage properties. Especially when the motor only pulls a few watts.

Anything up to 1.0 amp is probably more than enough for your application. Any of you electrical engineers can chime in any time to correct me.

For those who can't find anything but 110 vac, here's a sample pic of a Hansen 110 vac motor. It has (2) mounting tabs.

The advantage to using a 24vac motor, is it's low voltage and will not cause any major catastrophe if ever the unit would get submerged or doused.

Also you won't get any voltage leaks into your tank due to bad grounding. My understanding is, that anything under 30vac, does not require UL/CSA testing due to it's inherent low voltage properties. Especially when the motor only pulls a few watts.

Anything up to 1.0 amp is probably more than enough for your application. Any of you electrical engineers can chime in any time to correct me.

For those who can't find anything but 110 vac, here's a sample pic of a Hansen 110 vac motor. It has (2) mounting tabs.

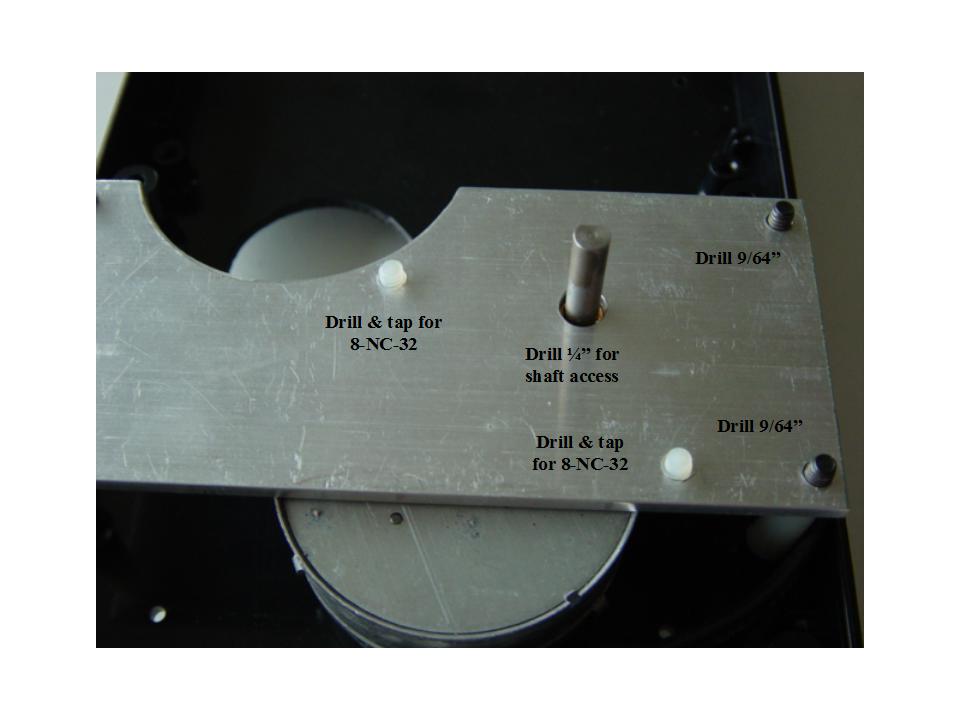

The plastic enclosure is made by Serpac, PN: 173-BK, it's main advantage it has edges which overlap to prevent salt creepage.

Most important though is the array of pre-molded stand-offs or bosses inside. these are where you tap threads inside the bosses to mount your motor plate assembly with nylon stand-offs and screws.

The large hole for the fixed pipe to pass through is drilled after you locate your motor mounting plate.

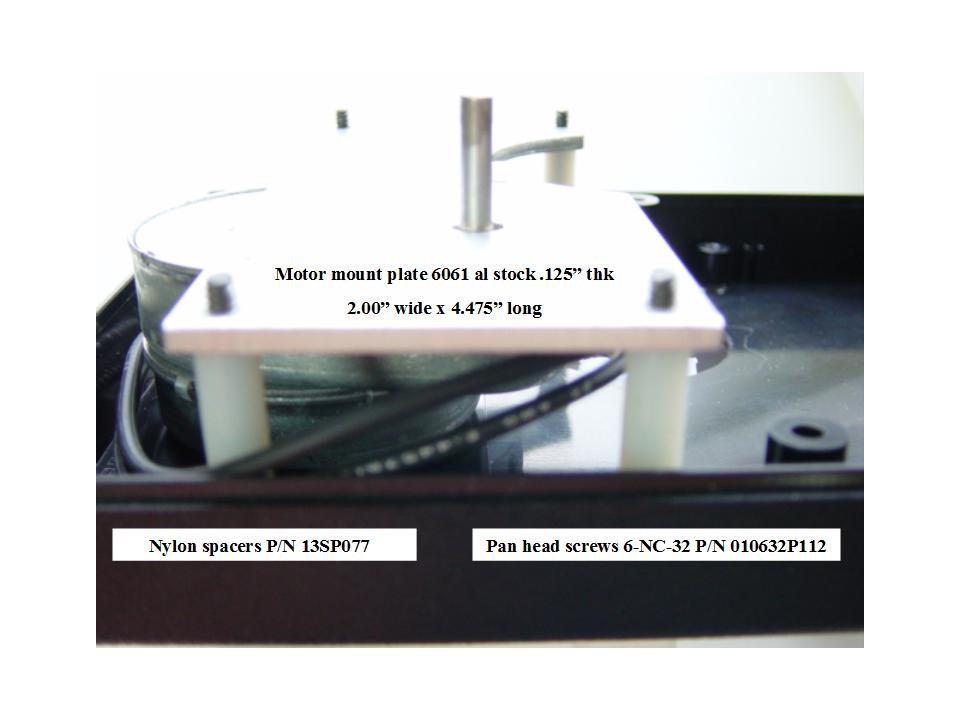

6/32 Spacers, (4) required, PN: 13SP077, Mfg: Microplastics

Motor mount plate, (1) required, 4.50" L x 2.00" W x .125" thk - AL 6061 Aluminum.

Plastic Enclosure Black, (1) required, PN: 173-BK, Mfg: Serpac

Use nylon screws everywhere to prevent any chance of corrosion from salt creep.

Most important though is the array of pre-molded stand-offs or bosses inside. these are where you tap threads inside the bosses to mount your motor plate assembly with nylon stand-offs and screws.

The large hole for the fixed pipe to pass through is drilled after you locate your motor mounting plate.

6/32 Spacers, (4) required, PN: 13SP077, Mfg: Microplastics

Motor mount plate, (1) required, 4.50" L x 2.00" W x .125" thk - AL 6061 Aluminum.

Plastic Enclosure Black, (1) required, PN: 173-BK, Mfg: Serpac

Use nylon screws everywhere to prevent any chance of corrosion from salt creep.

Similar threads

- Replies

- 1

- Views

- 80