Hey guys!

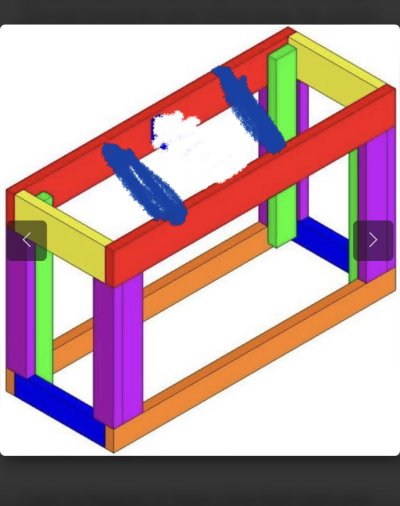

Will be upgrading my 70 gallon DT to 150 gallon DT (60L X 24W X 24H) and trying to come up with a plan to build the wooden stand.

Bare with me- I have little knowledge in carpentry and will be having my husband build it but want to make sure we are using strong enough lumber.

Would using 4X4's as the posts, 2X4's (or 2X6's) as the braces work? We are having a internal overflow centered in the back of the tank- how many cross braces do I need? I am assuming I do not need to have a solid wood counter-top and bracing works?

Anything special to take note of I need to do?

Will be upgrading my 70 gallon DT to 150 gallon DT (60L X 24W X 24H) and trying to come up with a plan to build the wooden stand.

Bare with me- I have little knowledge in carpentry and will be having my husband build it but want to make sure we are using strong enough lumber.

Would using 4X4's as the posts, 2X4's (or 2X6's) as the braces work? We are having a internal overflow centered in the back of the tank- how many cross braces do I need? I am assuming I do not need to have a solid wood counter-top and bracing works?

Anything special to take note of I need to do?