Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1000G Puffer Display

- Monster Build

- Thread starter x_burt

- Start date

- Tagged users None

It will be expensive but it is an important factor in putting a big and otherwise also expensive system together. Ask "him" for the price to make the stand with 304 stainless, also. You will need to know which wall thickness he is pricing. It is very important to structural strength. Is he capable of doing the structural analysis for you to determine all of the design features, such as fewer legs, tube size, wall thickness, etc.?

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

Note: Even cheap stainless rust over time. I agree with @fab if you are going to do stainless, have it build with the best you can get.

Last edited:

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

You to butt well, and to every one else that is reading today Happy Easter

Last edited:

Wow I'm deck sly following this build! The house is beautiful I can only imagine what the tank will look like

Fishroom:

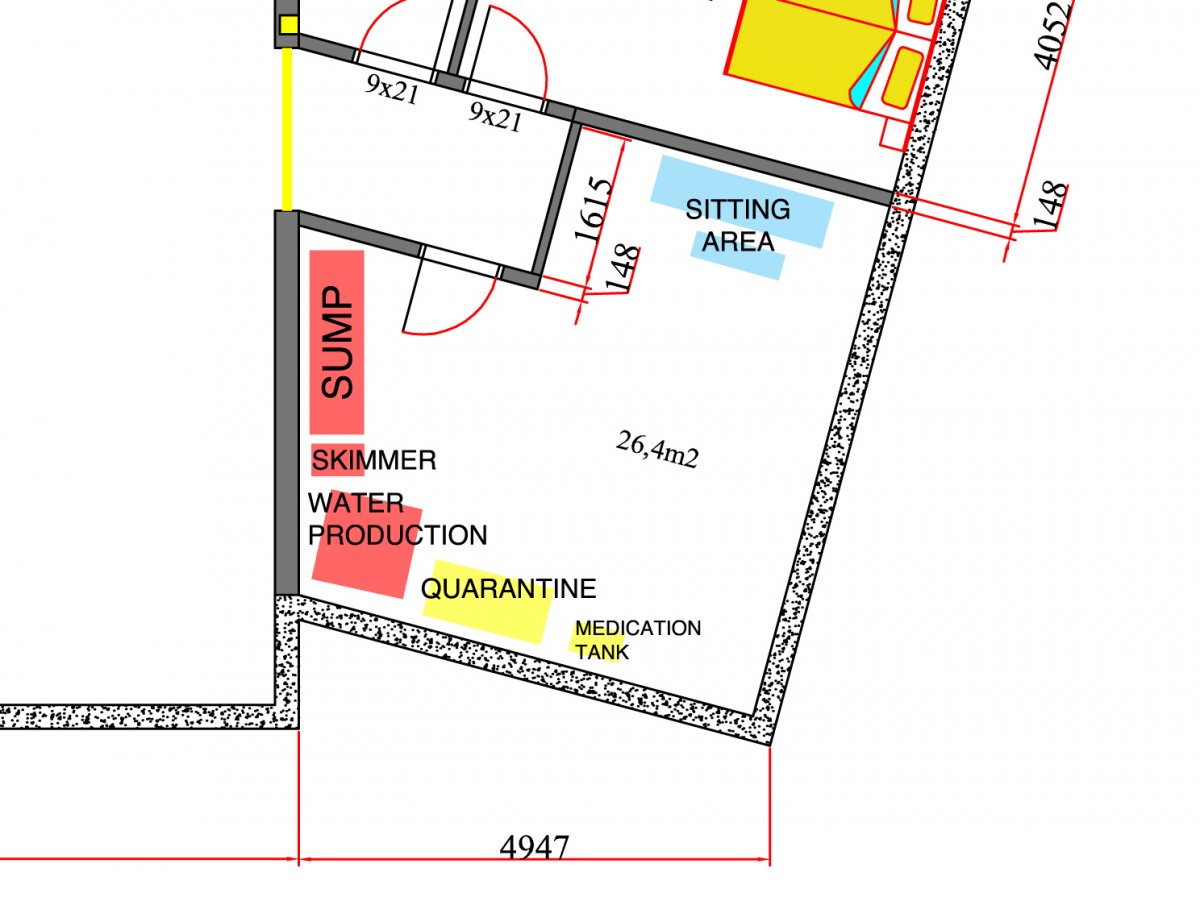

So I now have enough room for the filtration, quarantine, maybe future breeding projects and a place to hang out and talk fish, my aquatic mancave!

I have had a drain put in the floor and I will make it so water changes etc run easily and smoothly. No more carrying water! Any ideas/tips before we start are very welcome!

x_burt,

Nice, nice, nice, fish | equipment room!!! Good size, even if it is in square meters

1. Add a refrigerator and a freezer in the equipment room. Make it big enough but not too big. Your wife will want to use it if you make it too big.

2. Add a window into the equipment room from the small foyer entrance way so you can just take a quick peek into the room and make sure things "look right." It looks like the window could look right over the sump and water production area in your diagram.

3. Make sure the floor drain is does not have metal parts. You will be running saltwater into it. You don't want it rusting out underneath your new home.

4. Be sure to have what we call a "slop sink" in your equipment room, preferably one with two sides and with hot and cold water.

5. Provide yourself a kitchen-style small worksurface for mixing chemicals, food processing, and handling foodstuffs square meter or so should suffice. Look at restaurant supply companies for integrated units. Doing the work surface in a plastic material or in stainless steel works well. You want it to be easy to clean quickly. Overhead kitchen cabinets.

6. Preferably the slop-sink, refrigerator, and this worksurface should be close together in an efficient work triangle as you would provide in your main kitchen.

7. A garbage disposal unit is also very useful, but a bit of a luxury. It helps avoid the development of stink. I do not know what they are called on your side of the pond, but I mean a grinder that disposes of food waste directly into the waste water lines.

8. In addition to the floor drain, which should be limited to draining spillage, have your plumber install a proper drain to dump large quantities of water into a opposed to water just pouring out of a faucet. I did this in parallel to my slop sink drain. My garbage disposal drains into this same waste water line. I do protect the disposer from saltwater getting into it and sitting. It would deteriorate.

9. Run a live video feed from one or two cameras from your display tank to the equipment room. One of these cameras (you may need two) could be looking straight down on the display tank from within your canopy. Similarly, run one or more camera feeds to a place near your display tank where you can observe your sump and water processing equipment. I use cameras linked to my Apex controller and Neptune Systems' Fusion web interface for these camera feeds. I can pick up the video from a laptop or a phone. I can display them on a TV monitor. It makes split-based operations a lot more practicable. I can also call up the video remotely from wherever I have an internet connection, locally or out of the country.

10. Beef up the electrical house circuits for the equipment room. I have a separate electrical service panel that provide electrical service to my equipment room. It supplies several electrical circuits so that I do not encounter any amperage limitations.

11. I haven't done this yet, but I will be adding it to my system. I saw it as a technique described by a poster on a forum, maybe this forum. He has two lamps in his equipment room that he uses as a "semaphore" to members of his family. The lamps make the equipment room glow with either Green or with Red lighting which can be seen through a window into the equipment room. You could use LEDs instead and mount them outside the equipment room so they are easy to see, yet visually subtle and unobtrusive. RULES of usage: Whenever anyone feeds the fish, they turn on the lamp with a Green light signalling that the fish have been fed. After an appropriate time delay, the light turns off and the other one with a Red light turns on automatically, signalling that the fish need to be fed. When anyone feeds the fish, he turns off the Red light and turns on the Green light. By using an Apex controller to turn the lamp outlets ON and OFF you can remotely access the states of these two outlets and know whether the fish need to be fed or not. Of course remotely could be from your kitchen, office or hotel room when you are away on a trip. Additionally you could run two -way switches and LED indicator lights up to the display tank so you can see the feeding status on the LEDs and manually control the lamps from the 2-way switches next to the display tank. These remote switches would not be normal power switches, they would simply be switches that signal for the controller what you want the lights to do and the controller controls the power outlet accordingly.

You did say,

I hope I am not too late with these past minute puts for you.Any ideas/tips before we start are very welcome!

best regards,

fab

Last edited:

x_burt,

An item I recommend you consider seriously for water processing is a new algae scrubber built by a member of this R2R forum. He calls it the "Turbo Algae Scrubber." You can read all about it on R2R. Here are links for general information on algae scrubbers, in the event you are not familiar with them:

https://www.reef2reef.com/threads/algae-turf-scrubbers.61338

and for his specific, newly upgraded, algae scrubber:

https://www.reef2reef.com/threads/introducing-the-new-turbo-algae-scrubber-rev-4.212728/

It looks to me like his larger models will do a remarkable job on our tanks. He refers to these as models L8 and L16. He hasn't shipped any of his newest (revision 4) large models yet. They might start shipping in June, 2016. People who have begun receiving the smaller Rev 4 models (L2 & L4) rave over their quality of construction. People who have older models, long in service, rave over their function. People who have both also rave over the design improvements over the older models.

I have a 450 L remote refugium and a 250 L remote deep sand bed in my system. It is possible that this algae scrubber may be able to replace one of them, freeing up a lot of space. They are both standalone subsystems. They are fed water by pumps in my sump and the water drains back to the sump. The scrubber mounts above the sump and will hook up the same way in my system. You could plumb one in-line with your returns from the display tank upstairs, or at least in parallel to the return lines.

Personally, I do not like the idea of such an in-line plumbing configuration for reliability reasons. I am concerned about water lines clogging for any number of reasons. I try to design to minimize that likelihood and to protect against serious problems developing when it eventually does occur. I also prefer subsystems to be as independent of each other as possible, particularly plumbing-wise.

An item I recommend you consider seriously for water processing is a new algae scrubber built by a member of this R2R forum. He calls it the "Turbo Algae Scrubber." You can read all about it on R2R. Here are links for general information on algae scrubbers, in the event you are not familiar with them:

https://www.reef2reef.com/threads/algae-turf-scrubbers.61338

and for his specific, newly upgraded, algae scrubber:

https://www.reef2reef.com/threads/introducing-the-new-turbo-algae-scrubber-rev-4.212728/

It looks to me like his larger models will do a remarkable job on our tanks. He refers to these as models L8 and L16. He hasn't shipped any of his newest (revision 4) large models yet. They might start shipping in June, 2016. People who have begun receiving the smaller Rev 4 models (L2 & L4) rave over their quality of construction. People who have older models, long in service, rave over their function. People who have both also rave over the design improvements over the older models.

I have a 450 L remote refugium and a 250 L remote deep sand bed in my system. It is possible that this algae scrubber may be able to replace one of them, freeing up a lot of space. They are both standalone subsystems. They are fed water by pumps in my sump and the water drains back to the sump. The scrubber mounts above the sump and will hook up the same way in my system. You could plumb one in-line with your returns from the display tank upstairs, or at least in parallel to the return lines.

Personally, I do not like the idea of such an in-line plumbing configuration for reliability reasons. I am concerned about water lines clogging for any number of reasons. I try to design to minimize that likelihood and to protect against serious problems developing when it eventually does occur. I also prefer subsystems to be as independent of each other as possible, particularly plumbing-wise.

Last edited:

x_burt,

I sent a pm.

Wall thicknesses for stainless steel tank frame members:

The 3x2 used on the base is .120 inch wall thickness. The 2x2 is .083 inch wall thickness. The heavier wall for the base was primarily for welding in the threaded spools for the feet.

I sent a pm.

Wall thicknesses for stainless steel tank frame members:

The 3x2 used on the base is .120 inch wall thickness. The 2x2 is .083 inch wall thickness. The heavier wall for the base was primarily for welding in the threaded spools for the feet.

Have you considered putting a small ledge in front of your tank? Like a tiny counter 10-15 cm protrusion running the length of the tank ...to rest an elbow, set down a drink or a container of fish food?

Mine is a 5 inch ledge in granite. It mounts to the plywood sheet which extends out 3 inches from under my tank.

Mine is a 5 inch ledge in granite. It mounts to the plywood sheet which extends out 3 inches from under my tank.

jsker

Reefing is all about the adventure

View Badges

Staff member

Super Moderator

Partner Member 2024

Excellence Award

Reef Tank 365

Article Contributor

Hospitality Award

Ocala Reef Club Member

R2R Secret Santa 2023

My Tank Thread

Your fan base has grown

x_burt,

Nice, nice, nice, fish | equipment room!!! Good size, even if it is in square meters. I have some more recommendations for you. These are for the equipment room. Perhaps it is not too late to do these.

1. Add a refrigerator and a freezer in the equipment room. Make it big enough but not too big. Your wife will want to use it if you make it too big.

I have a freezer already from my old house that I will be using for the puffers food etc. haha I put the wifes in the right by the kitchen so she doesnt have to come downstairs near mine!

2. Add a window into the equipment room from the small foyer entrance way so you can just take a quick peek into the room and make sure things "look right." It looks like the window could look right over the sump and water production area in your diagram.

I dont want a window, the idea of the fish room was to hide everything away i dont want to see any of it from outside the room.

3. Make sure the floor drain is does not have metal parts. You will be running saltwater into it. You don't want it rusting out underneath your new home.

Plumbing here is plastic so all good there.

4. Be sure to have what we call a "slop sink" in your equipment room, preferably one with two sides and with hot and cold water.

I have a sink, water and also access to the sewage pipe should I need it.

5. Provide yourself a kitchen-style small worksurface for mixing chemicals, food processing, and handling foodstuffs square meter or so should suffice. Look at restaurant supply companies for integrated units. Doing the work surface in a plastic material or in stainless steel works well. You want it to be easy to clean quickly. Overhead kitchen cabinets.

Work surface will be there. I want to have a full qt section so I want a microscope etc.

6. Preferably the slop-sink, refrigerator, and this worksurface should be close together in an efficient work triangle as you would provide in your main kitchen.

Havent decided the final layout yet, i'll do that once I finally get into the basement part of the house build, have to concentrate on one bit at a time right now!

7. A garbage disposal unit is also very useful, but a bit of a luxury. It helps avoid the development of stink. I do not know what they are called on your side of the pond, but I mean a grinder that disposes of food waste directly into the waste water lines.

They dont really do garbage disposals over here.

8. In addition to the floor drain, which should be limited to draining spillage, have your plumber install a proper drain to dump large quantities of water into a opposed to water just pouring out of a faucet. I did this in parallel to my slop sink drain. My garbage disposal drains into this same waste water line. I do protect the disposer from saltwater getting into it and sitting. It would deteriorate.

I have the main I can get into if needed

9. Run a live video feed from one or two cameras from your display tank to the equipment room. One of these cameras (you may need two) could be looking straight down on the display tank from within your canopy. Similarly, run one or more camera feeds to a place near your display tank where you can observe your sump and water processing equipment. I use cameras linked to my Apex controller and Neptune Systems' Fusion web interface for these camera feeds. I can pick up the video from a laptop or a phone. I can display them on a TV monitor. It makes split-based operations a lot more practicable. I can also call up the video remotely from wherever I have an internet connection, locally or out of the country.

Not sure how I feel about cameras.

10. Beef up the electrical house circuits for the equipment room. I have a separate electrical service panel that provide electrical service to my equipment room. It supplies several electrical circuits so that I do not encounter any amperage limitations.

The electricians have been prepped and so too has the ventilation guy and plumber so all will be done appropriatly!

11. I haven't done this yet, but I will be adding it to my system. I saw it as a technique described by a poster on a forum, maybe this forum. He has two lamps in his equipment room that he uses as a "semaphore" to members of his family. The lamps make the equipment room glow with either Green or with Red lighting which can be seen through a window into the equipment room. You could use LEDs instead and mount them outside the equipment room so they are easy to see, yet visually subtle and unobtrusive. RULES of usage: Whenever anyone feeds the fish, they turn on the lamp with a Green light signalling that the fish have been fed. After an appropriate time delay, the light turns off and the other one with a Red light turns on automatically, signalling that the fish need to be fed. When anyone feeds the fish, he turns off the Red light and turns on the Green light. By using an Apex controller to turn the lamp outlets ON and OFF you can remotely access the states of these two outlets and know whether the fish need to be fed or not. Of course remotely could be from your kitchen, office or hotel room when you are away on a trip. Additionally you could run two -way switches and LED indicator lights up to the display tank so you can see the feeding status on the LEDs and manually control the lamps from the 2-way switches next to the display tank. These remote switches would not be normal power switches, they would simply be switches that signal for the controller what you want the lights to do and the controller controls the power outlet accordingly.

Not a chance!! hahaha

You did say,

I hope I am not too late with these past minute puts for you.

best regards,

fab

x_burt,

An item I recommend you consider seriously for water processing is a new algae scrubber built by a member of this R2R forum. He calls it the "Turbo Algae Scrubber." You can read all about it on R2R. Here are links for general information on algae scrubbers, in the event you are not familiar with them:

https://www.reef2reef.com/threads/algae-turf-scrubbers.61338

and for his specific, newly upgraded, algae scrubber:

https://www.reef2reef.com/threads/introducing-the-new-turbo-algae-scrubber-rev-4.212728/

It looks to me like his larger models will do a remarkable job on our tanks. He refers to these as models L8 and L16. He hasn't shipped any of his newest (revision 4) large models yet. They might start shipping in June, 2016. People who have begun receiving the smaller Rev 4 models (L2 & L4) rave over their quality of construction. People who have older models, long in service, rave over their function. People who have both also rave over the design improvements over the older models.

I have a 450 L remote refugium and a 250 L remote deep sand bed in my system. It is possible that this algae scrubber may be able to replace one of them, freeing up a lot of space. They are both standalone subsystems. They are fed water by pumps in my sump and the water drains back to the sump. The scrubber mounts above the sump and will hook up the same way in my system. You could plumb one in-line with your returns from the display tank upstairs, or at least in parallel to the return lines.

Personally, I do not like the idea of such an in-line plumbing configuration for reliability reasons. I am concerned about water lines clogging for any number of reasons. I try to design to minimize that likelihood and to protect against serious problems developing when it eventually does occur. I also prefer subsystems to be as independent of each other as possible, particularly plumbing-wise.

An Algae scrubber is definitely something I will consider. I've done a couple before and they worked great but my current tank I have been using ATM Outbreak and I havent needed much else, even the skimmer doesnt have much to do!

Similar threads

- Replies

- 118

- Views

- 3,494

- Replies

- 2

- Views

- 91