90% infill now that is gonna cost me@ilikefish69, keep in mind that fdm doesn't create a water tight adhesion, to avoid filling the voids with water that will turn stagnant and possibly hypoxic, you'll want to consider printing at 90-100%.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3d Printed Aquarium Parts Archive

Cost you up front but potentially save you down the road.90% infill now that is gonna cost me

Everything I print that goes in the water is 90% or above. Petg is heavier than salt water so it's not as buoyant. When you factor in air trapped in the model, you're then required to figure out how to weigh it down. Drilling holes isn't a bad idea.

Then there's the biological side of what happens to the water that eventually secretes in while micro fauna can't? Hence the long term concerns.

I'd be curious what your slicer calculates the total filement used at 90% plus. I bet it's still cheaper than acrylic.

Something else to consider in your design, the walls look super thick, I bet you can get away with a 1.6-2mm wall in most places where water pressure is equal on both sides. You can probably slim that thing way down and cut back on material.

Then there's the biological side of what happens to the water that eventually secretes in while micro fauna can't? Hence the long term concerns.

I'd be curious what your slicer calculates the total filement used at 90% plus. I bet it's still cheaper than acrylic.

Something else to consider in your design, the walls look super thick, I bet you can get away with a 1.6-2mm wall in most places where water pressure is equal on both sides. You can probably slim that thing way down and cut back on material.

if you're down from 20mm thick to 5, it will be mostly walls anyways. you could probably drop to 2mm and make it 100% or really hot and slow first and last layer may seal it. cnc kitchen talks about it in his video on printing clear parts.90% infill now that is gonna cost me

Projects with Sam

5000 Club Member

View BadgesPartner Member 2024

Hospitality Award

Midwest Reefer

Rock Pool Reef Keepers

My Tank Thread

My Aquarium Showcase

The more I print the more I try to think about/find subtractive ways to manufacture things; additive is slow and in many cases is not necessary.

As we speak, I am working on cnc-carved light shades because I'm fed-up with finicky printer hot-end issues. maybe its because I got junk hot-ends.

I use this for so much stuff now its insane. Cuts with craft knives or router-bits; Glues with PVC cement or CA

As we speak, I am working on cnc-carved light shades because I'm fed-up with finicky printer hot-end issues. maybe its because I got junk hot-ends.

I use this for so much stuff now its insane. Cuts with craft knives or router-bits; Glues with PVC cement or CA

I don't think I've ever seen that. I'll have to look for it next time I'm at Menards. I have an entirely unrelated (to aquariums) use for it, possibly.

While still, I assume, slower than a CNC mill, I just replaced my Ender with a Bambu X1C. That thing goes so ungodly fast, how it makes such good prints, I don't know.additive is slow and in many cases is not necessary.

The thing goes fast enough that a lot of people showing it off will put a note in the video explaining that it's not sped up or a time lapse, it just goes this fast.

It's like getting an InstantPot when you've used a Crock Pot all your life.

Projects with Sam

5000 Club Member

View BadgesPartner Member 2024

Hospitality Award

Midwest Reefer

Rock Pool Reef Keepers

My Tank Thread

My Aquarium Showcase

I don't think I've ever seen that. I'll have to look for it next time I'm at Menards. I have an entirely unrelated (to aquariums) use for it, possibly.

While still, I assume, slower than a CNC mill, I just replaced my Ender with a Bambu X1C. That thing goes so ungodly fast, how it makes such good prints, I don't know.

The thing goes fast enough that a lot of people showing it off will put a note in the video explaining that it's not sped up or a time lapse, it just goes this fast.

It's like getting an InstantPot when you've used a Crock Pot all your life.

I've made overflows with it; filter floss rollers, all sorts of stuff; cutting both by hand and on a cnc.

Hello,

I designed an Inkbird mount to hold the controller and the plugs. Can we add it to the list please?

www.printables.com

www.printables.com

Thanks!

Brett

I designed an Inkbird mount to hold the controller and the plugs. Can we add it to the list please?

Printables

Thanks!

Brett

Anyone have a good way to mount some light bars to 2 xr30s? I was thinking possibly a 3d printed bracket? Any ideas?

Projects with Sam

5000 Club Member

View BadgesPartner Member 2024

Hospitality Award

Midwest Reefer

Rock Pool Reef Keepers

My Tank Thread

My Aquarium Showcase

Checkout the market - there are a few folks on here that make great light mounts in the 3D printed section.Anyone have a good way to mount some light bars to 2 xr30s? I was thinking possibly a 3d printed bracket? Any ideas?

I personally don't know if I'd trust a 3d print to hold up an xr30.Anyone have a good way to mount some light bars to 2 xr30s? I was thinking possibly a 3d printed bracket? Any ideas?

Although, I wouldn't pay the price of the ones offered by etm.

I cut these out of 6mm thick acrylic with my laser

I would use some 3/4 aluminum angle iron or simmilar material instead, plastic works good for some applications but has a tendency to sag under weight over time. A light mount is something best made from a more rigid material imoAnyone have a good way to mount some light bars to 2 xr30s? I was thinking possibly a 3d printed bracket? Any ideas?

do you have a facebook? I helped a gentleman hang a new AI Blade light bar to a HMS rail. I still don't know exactly how he did it, but I printed these things for him and he made it work. I can connect the two of you , let me knowAnyone have a good way to mount some light bars to 2 xr30s? I was thinking possibly a 3d printed bracket? Any ideas?

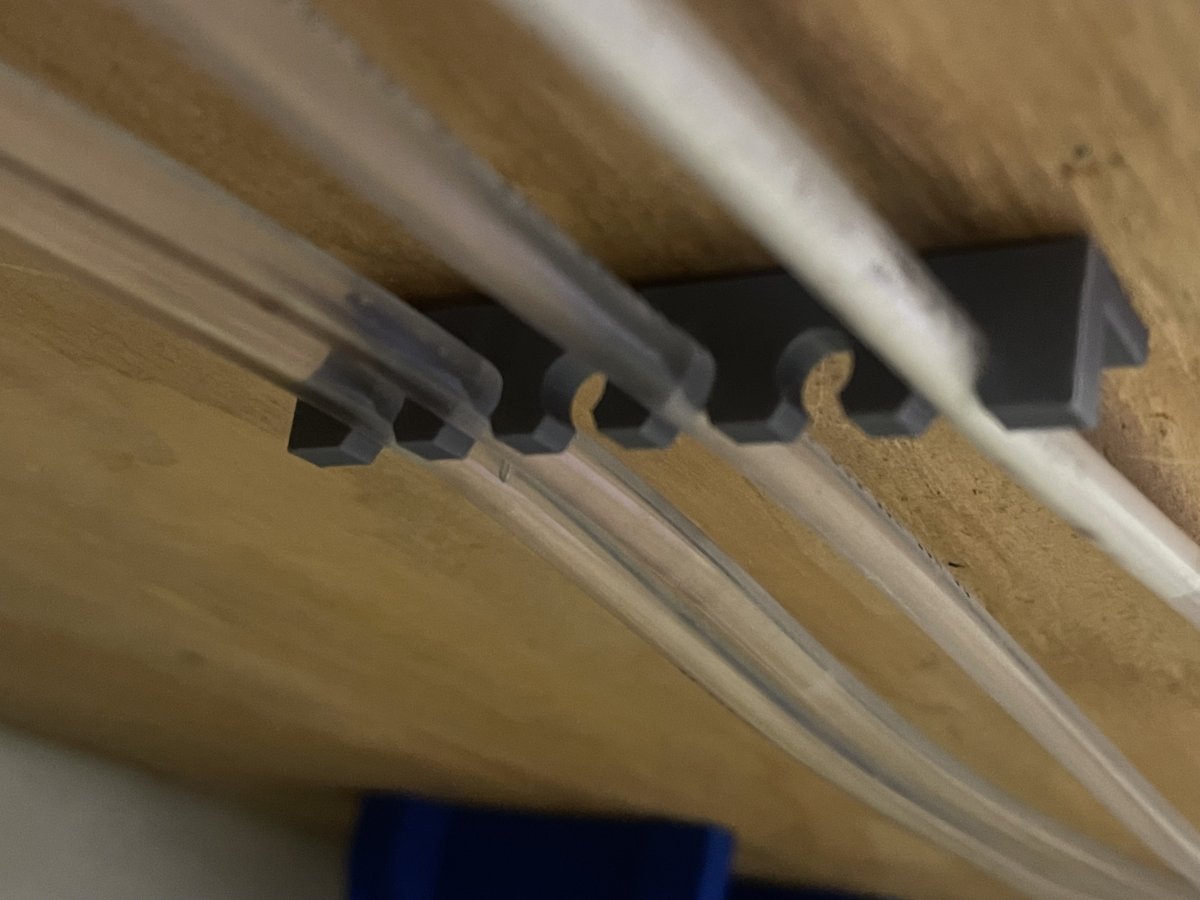

A quick 1/4" Tube holder I put together. This allows you to run your tubing along the wall, and prevent them from hanging all over the place. Enjoy =).

www.thingiverse.com

www.thingiverse.com

1/4" Dosing Tube Holder by macdaddynick1

This is to organize your dosing tubes in the stand and prevent them from hanging everywhere.

Last edited:

Cap for a regular water 5-gallon jug that incorporates a 1/4" John guest bulkhead, to turn it into a 5 Gallon Dosing container. Enjoy.

www.thingiverse.com

www.thingiverse.com

5 Gallon Jug, to 1/4" John Guest Bulkhead by macdaddynick1

This turns your 5-gallon jug into a dosing container.

Hey Guys - Anyone has mesh for ECm 63 - Panta Rhei - to avoid small fish from sucking into the hydra flow ?

Additionally I need help with a few custom printed parts - 1) Overflow cap 2) Cap for refugium with hold to accommodate AI Fuge.

Additionally I need help with a few custom printed parts - 1) Overflow cap 2) Cap for refugium with hold to accommodate AI Fuge.

Projects with Sam

5000 Club Member

View BadgesPartner Member 2024

Hospitality Award

Midwest Reefer

Rock Pool Reef Keepers

My Tank Thread

My Aquarium Showcase

Hi, I may have something that you could use for the overflow cap:Hey Guys - Anyone has mesh for ECm 63 - Panta Rhei - to avoid small fish from sucking into the hydra flow ?

Additionally I need help with a few custom printed parts - 1) Overflow cap 2) Cap for refugium with hold to accommodate AI Fuge.

Short Drain Strainer for 1-1/2 inch pipe

This short strainer (1-1/4" from the top of the pipe) extends below the pipe to allow for enough water to flow into the drain. printed in PETG

I got tired of knocking my Hanna checker cuvettes over all the time while I had them standing upside down drying on paper towels. Made a quick and dirty drying rack.

https://www.thingiverse.com/thing:6213983

https://www.thingiverse.com/thing:6213983

Hi all,

I asked if I could help organize this sticky, and @revhtree made me the owner. I mainly wanted to update the first post in the thread to include all the things people have posted, so it's all in once place. I was also going to take a stab at organizing it a bit more. I think it would be nice if all the models for a particular purpose or piece of gear were together. Wish me luck!

Brett

I asked if I could help organize this sticky, and @revhtree made me the owner. I mainly wanted to update the first post in the thread to include all the things people have posted, so it's all in once place. I was also going to take a stab at organizing it a bit more. I think it would be nice if all the models for a particular purpose or piece of gear were together. Wish me luck!

Brett

Similar threads

- Replies

- 35

- Views

- 1,700

- Replies

- 47

- Views

- 1,368

- Replies

- 10

- Views

- 694

- Replies

- 6

- Views

- 399