Hello R2R members,

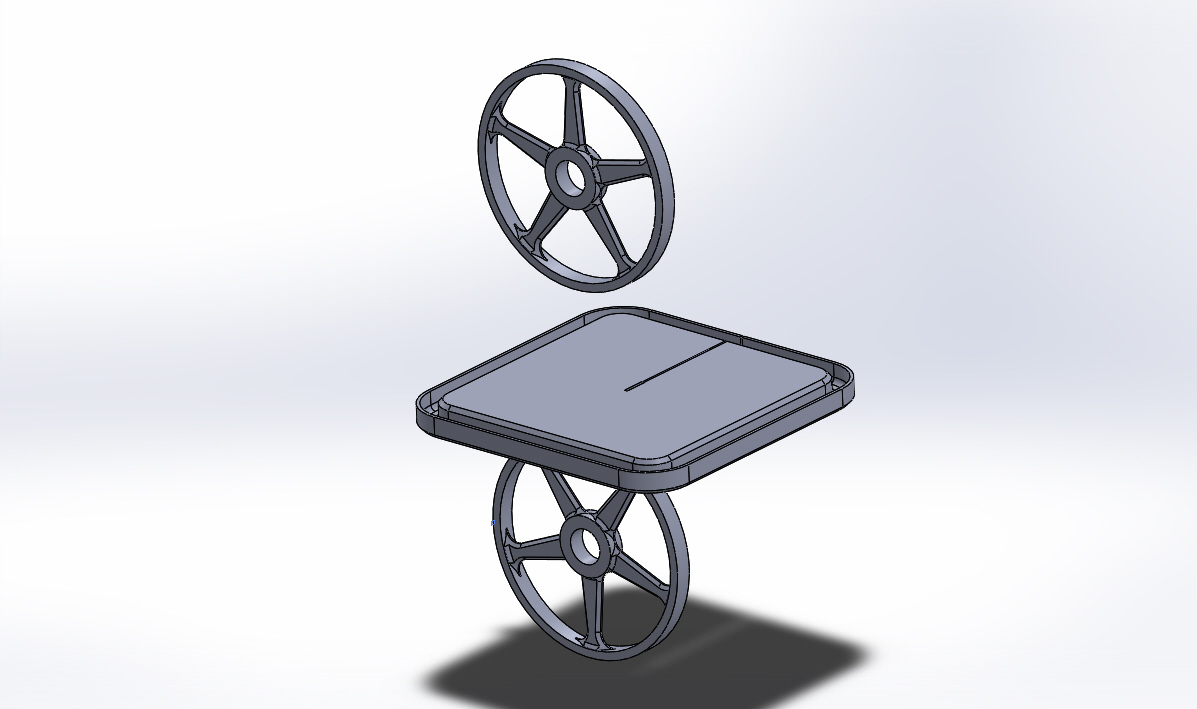

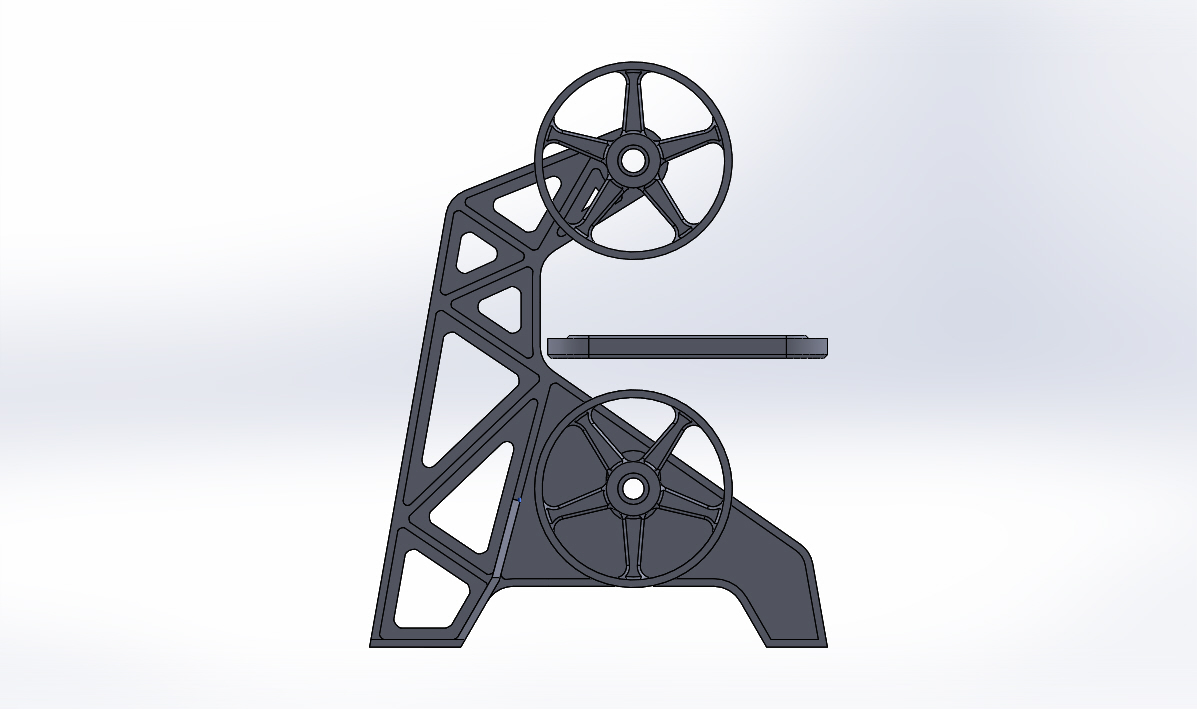

I was looking into purchasing a bandsaw for cutting up some frags. During my search, I noticed that several people where not satisfied with some design aspects of the current saws on the market. So I made a list of the design upgrades that I would like mine to have, and decided that I will attempt to print one. I'm in the early stages of the CAD drawing, but will update the thread as I make more progress. I'm on not sure if I want to run this type of frame for the saw yet.

Please feel free to make design suggestions on what you would like to see on a saw.

I was looking into purchasing a bandsaw for cutting up some frags. During my search, I noticed that several people where not satisfied with some design aspects of the current saws on the market. So I made a list of the design upgrades that I would like mine to have, and decided that I will attempt to print one. I'm in the early stages of the CAD drawing, but will update the thread as I make more progress. I'm on not sure if I want to run this type of frame for the saw yet.

Please feel free to make design suggestions on what you would like to see on a saw.

Last edited: