- Joined

- Oct 10, 2019

- Messages

- 137

- Reaction score

- 201

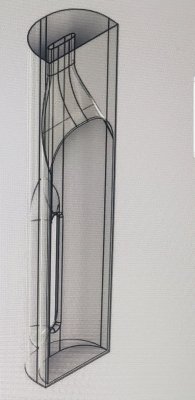

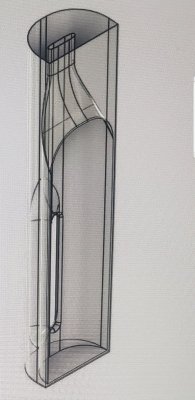

Ok so I'm not sure if this is where to post this but I'm looking into 3d printers to print filters (for sale) for reef tanks would anyone have any info on a good 3d printer capable of printing at a fast enough rate for distribution purposes I'm looking for something in the 5k price point that has a build height of around 13 inches any help would be appreciated