If you post a picture of the power brick I can make a model for you. I can only print it out depending on its final size though, my printer maxes out at 8x8" for the build area.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printing thread

- Thread starter PurpleMonster

- Start date

- Tagged users None

Thanks @biecacka , it occurs to me that this is basically a painted bench top PSU. I did a search on thingiverse with those terms and found this item: https://www.thingiverse.com/thing:846157

Would something like that work for you? Or are you looking for a full cradle for the bottom of the PSU to fit into?

Would something like that work for you? Or are you looking for a full cradle for the bottom of the PSU to fit into?

- Joined

- Jul 1, 2019

- Messages

- 243

- Reaction score

- 185

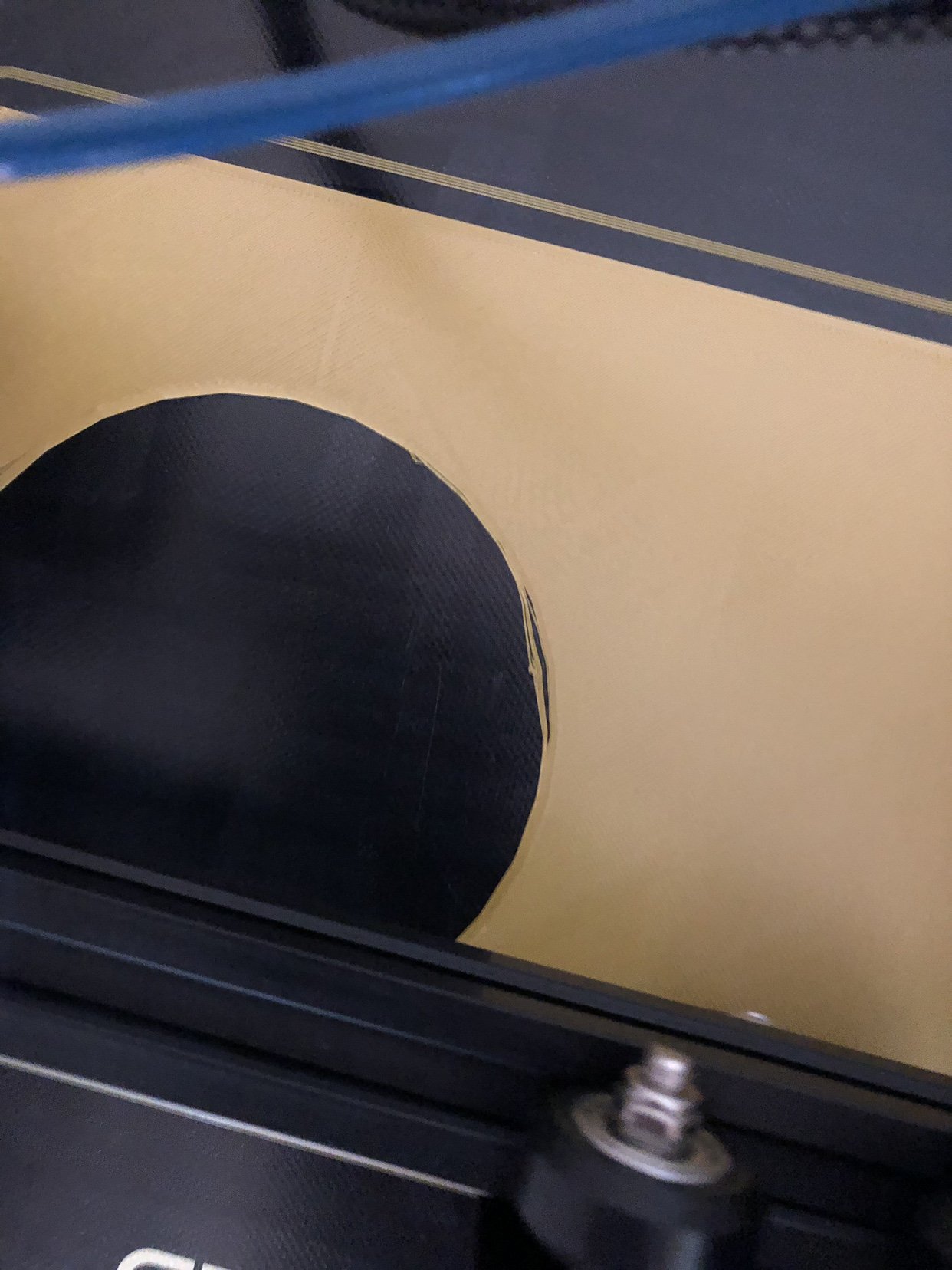

The spacing on your skirt looks a little wide, I would check your first layer height.

We can't sell via R2R without posting it in the marketplace and paying to do so.

We don't want anyone in trouble for doing so.

We don't want anyone in trouble for doing so.

- Joined

- Jun 24, 2014

- Messages

- 486

- Reaction score

- 294

The spacing on your skirt looks a little wide, I would check your first layer height.

What is the best first layer height ?

- Joined

- Jul 1, 2019

- Messages

- 243

- Reaction score

- 185

Most materials are 0.2mm. 0.35 for PETG.

The printer itself needs to have the Z-offset set correctly so it corresponds with the first layer height you have set in the slicing software.

I typically measure the skirt from the last print to know if I need to adjust it for the next print. If the skirt is 0.25mm thick while you have the software set for 0.2mm then you will have to adjust the Z-offset 0.05mm on the printer.

You can cheat a little bit with some filaments (like PLA) to smoosh down a first layer, (measures 0.18mm when set to 0.2mm etc) but you will want to have these values close or it wont extrude the right amount of filament.

If the Z-offest is too high on the first layer, the filament looks thin and stringy and will pull away from inside corners because it's barley laying on the surface, as not enough plastic was extruded to fill the gap between the nozzle and the bed.

The printer itself needs to have the Z-offset set correctly so it corresponds with the first layer height you have set in the slicing software.

I typically measure the skirt from the last print to know if I need to adjust it for the next print. If the skirt is 0.25mm thick while you have the software set for 0.2mm then you will have to adjust the Z-offset 0.05mm on the printer.

You can cheat a little bit with some filaments (like PLA) to smoosh down a first layer, (measures 0.18mm when set to 0.2mm etc) but you will want to have these values close or it wont extrude the right amount of filament.

If the Z-offest is too high on the first layer, the filament looks thin and stringy and will pull away from inside corners because it's barley laying on the surface, as not enough plastic was extruded to fill the gap between the nozzle and the bed.

I agree with the above. I used to aim for this, now, I just set it on the fly by leveling the bed manually to get a little smoosh.

Works out great.

Works out great.

Stringing like that tends to be temperature related or even a clogged nozzle.

What is the material you are using and temps?

What is the material you are using and temps?

- Joined

- Jun 24, 2014

- Messages

- 486

- Reaction score

- 294

Stringing like that tends to be temperature related or even a clogged nozzle.

What is the material you are using and temps?

PETG 245 and 80 glass bed

I dropped and broke my brand new MP60, I turned to the 3D printer to save the day!

What did you use to get such a nice model?

- Joined

- Jun 24, 2014

- Messages

- 486

- Reaction score

- 294

PETG 245 and 80 glass bed

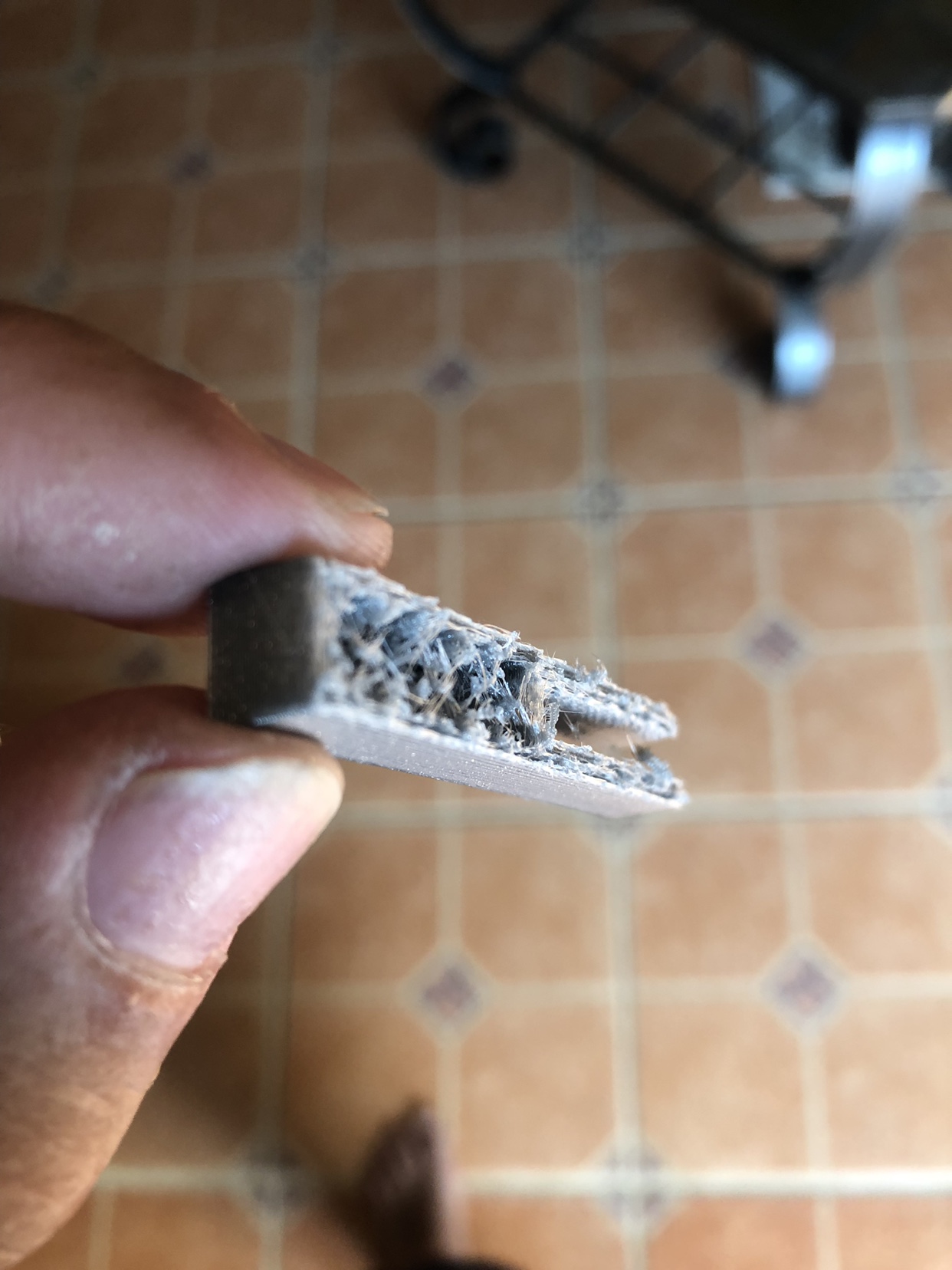

Also my filment is breaking sometimes in this point

Anyone why is this happening

It looks like maybe your nozzle (or someplace between the nozzle and the extruder) is getting clogged, so the teeth on the extruder are grinding up the filament instead of pushing it smoothly along.

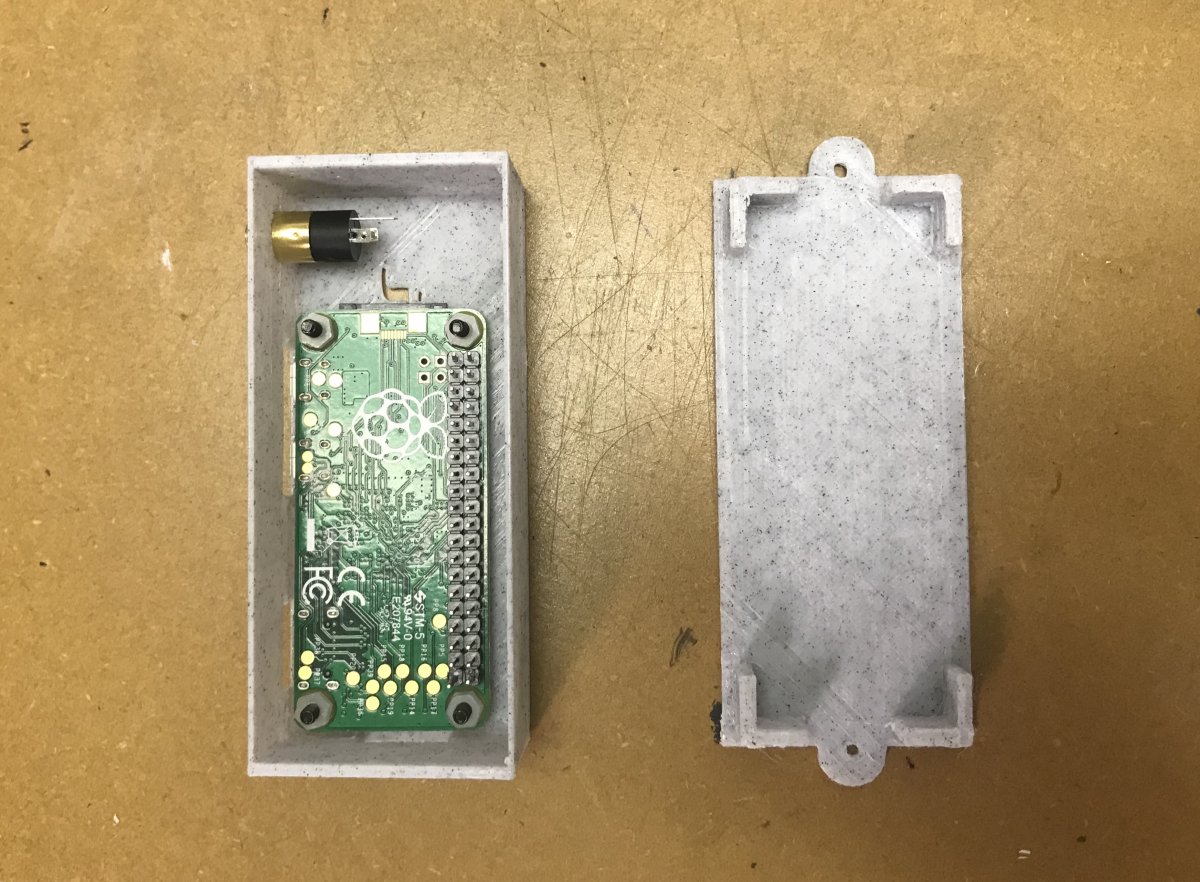

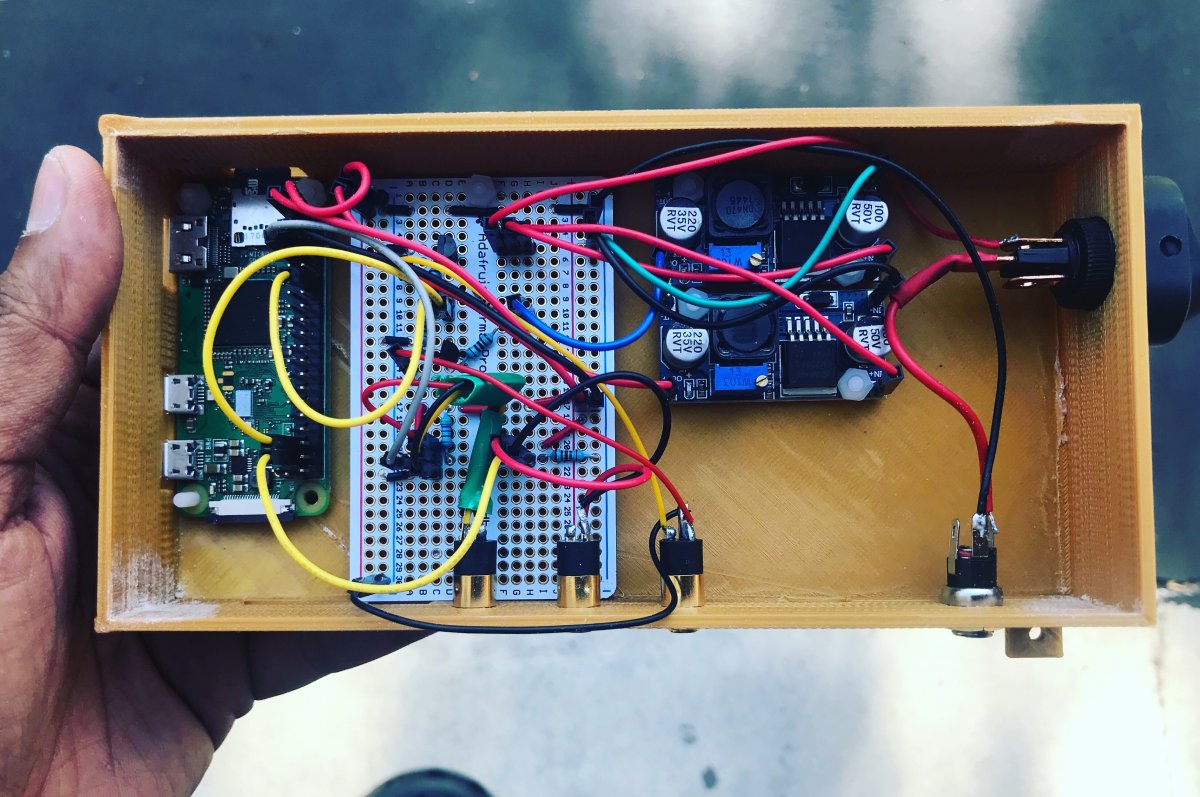

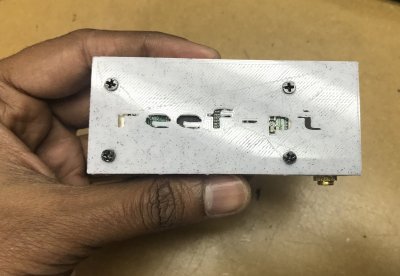

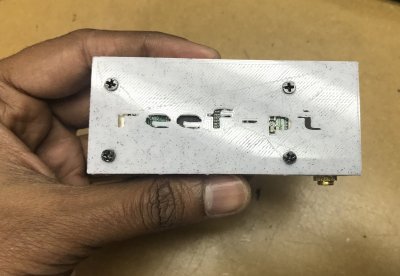

Hello friends,

Been printing for only past one month. Got myself a creality ender 3. My main goal was to print enclosures for my controllers, various contraptions for sensors, tubes etc. Still a long way to go in terms of modelling. I am using Blender for modelling and Cura for slicing. Ender 3 is controlled by an octoprint instance running on Raspberry Pi (not octopi, but my hand rolled installation on raspbian). Printer hardware is stock, except the upgraded glass build plate.

Overall, I am very happy with the results. My prints are far from perfect, but they are functional, accurate enough for me to build the structural components with millimeter level error tolerance. I am using sanding/filing as last-mile solution. I have only used PLA till now, but planning to use PETG next (and upgrade to Capricorn tubing).

Here are few of my simple designs

Other than these enclosures, I printed reefing relevant available designs from Thingiverse extensively. Stuff like floatswitch contraption by @sfgabe , mp 10 bracket by @Alemoki etc. I am printing a custom filter for my 3.7G pico tank as I write this post. This will be extremely useful . Me and my son enjoy watching 3d printers in action.

. Me and my son enjoy watching 3d printers in action.

I am curious if you all use any common tag or something that I can use to search designs in thingiverse.

Just wanted to drop by and share my experience. Thank you for sharing all your learning.

Been printing for only past one month. Got myself a creality ender 3. My main goal was to print enclosures for my controllers, various contraptions for sensors, tubes etc. Still a long way to go in terms of modelling. I am using Blender for modelling and Cura for slicing. Ender 3 is controlled by an octoprint instance running on Raspberry Pi (not octopi, but my hand rolled installation on raspbian). Printer hardware is stock, except the upgraded glass build plate.

Overall, I am very happy with the results. My prints are far from perfect, but they are functional, accurate enough for me to build the structural components with millimeter level error tolerance. I am using sanding/filing as last-mile solution. I have only used PLA till now, but planning to use PETG next (and upgrade to Capricorn tubing).

Here are few of my simple designs

Other than these enclosures, I printed reefing relevant available designs from Thingiverse extensively. Stuff like floatswitch contraption by @sfgabe , mp 10 bracket by @Alemoki etc. I am printing a custom filter for my 3.7G pico tank as I write this post. This will be extremely useful

I am curious if you all use any common tag or something that I can use to search designs in thingiverse.

Just wanted to drop by and share my experience. Thank you for sharing all your learning.

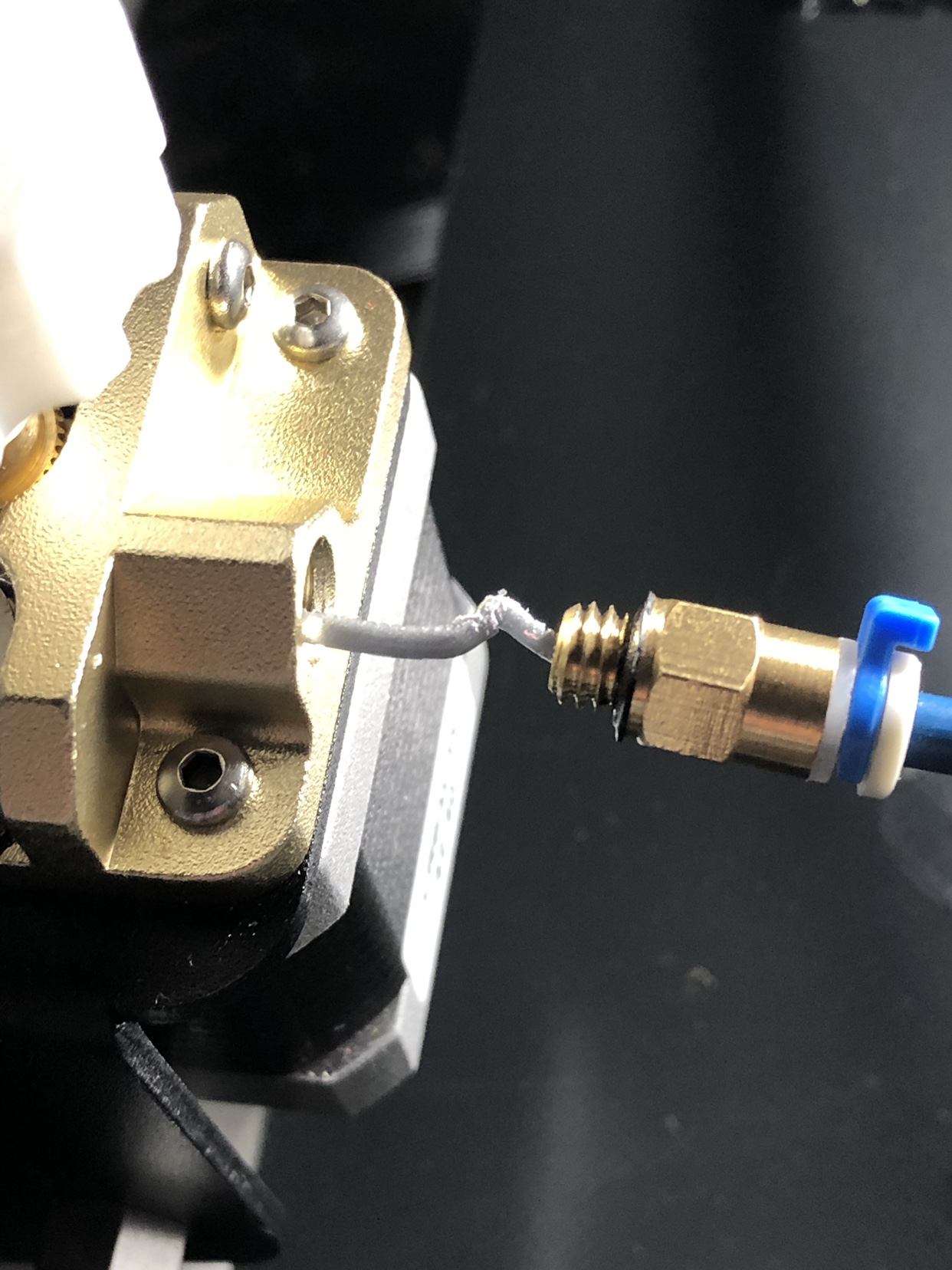

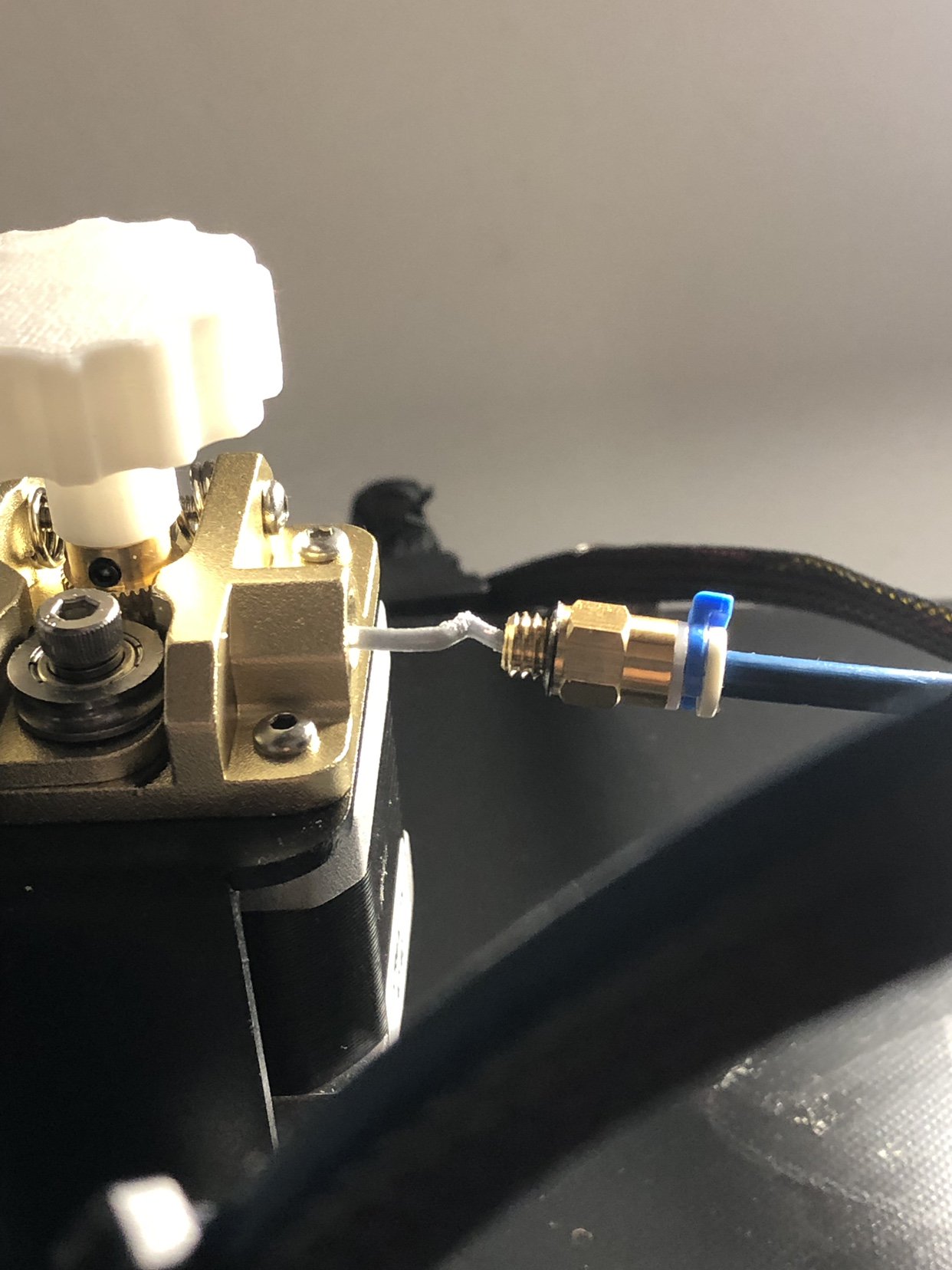

Like @Larry L said, I would look for a clog downstream from the extruder. In my experience prolonged printing on the Ender using the stock head at 245, will eventually degrade the PTFE tube end that's inserted into the hot end. Heat up the hot end pull out the tube and see if the end is melted or deformed.Anyone why is this happening

If it's simply deformed, replace it.

If it's melted, you will need to replace it but you may also have some of he PTFE tube stuck down in the nozzle, which will need to be cleaned out.

Last edited:

- Joined

- Jun 24, 2014

- Messages

- 486

- Reaction score

- 294

Like @Larry L said, I would look for a clog downstream from the extruder. In my experience prolonged printing on the ENder using the stock head at 245, will eventually degrade the PTFE end thats inserted into the hot end. Heat up the hot end pull out the tube and see if the end is melted or deformed.

If it's simply deformed, replace it.

If it's melted, you will need to replace it but you may also have some of he PTFE tube stuck down in the nozzle, which will need to be cleaned out.

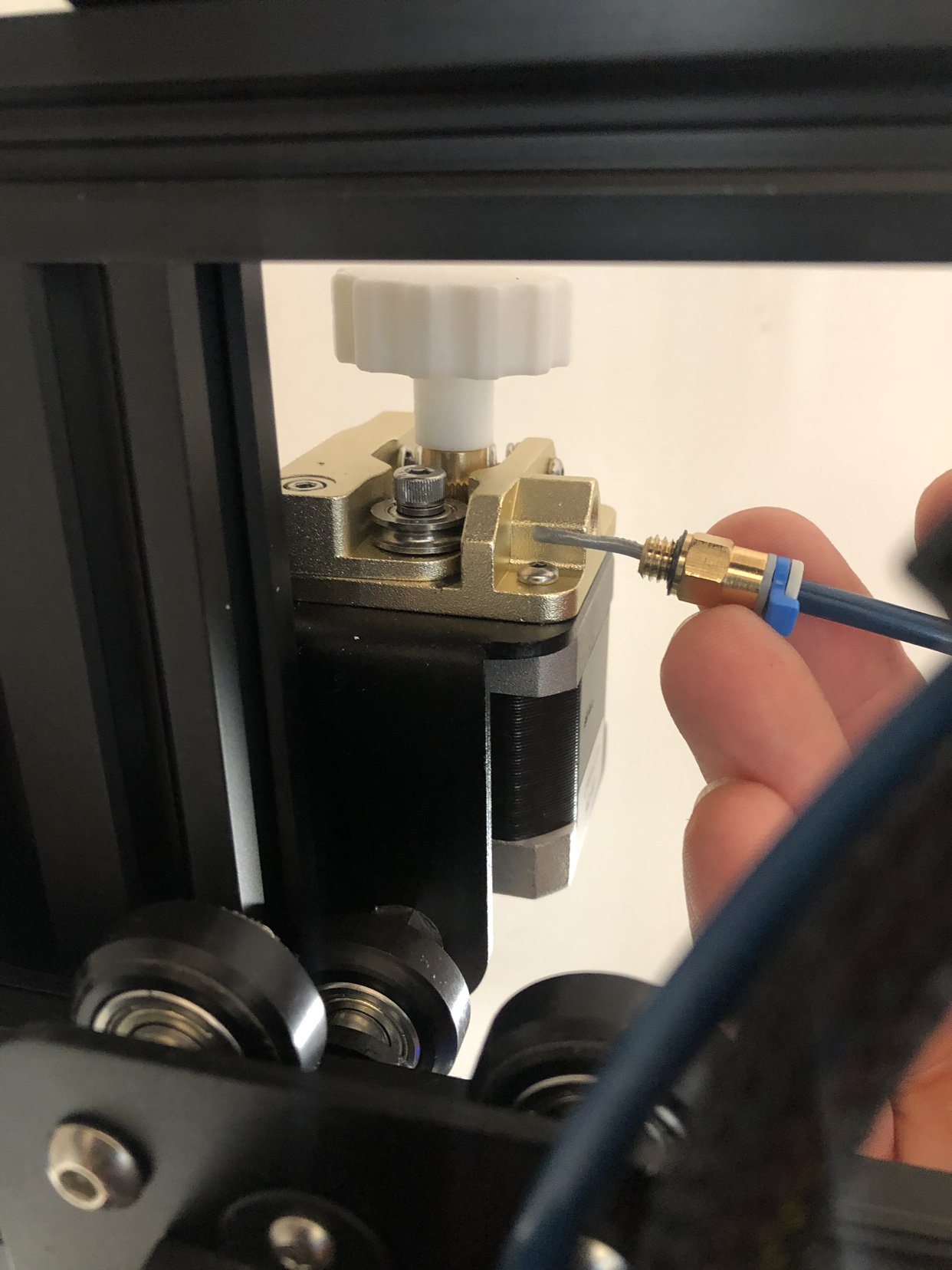

I tried to remove the nozzle and can't get un Screwed any tips or tricks how to remove it

You may simply be able to depress the quick connect an then pull the tube out. This does not always work though. If this is the case, the use a small wrench to unscrew the quick connect (like you did for the extruder). One of the wrenches they included in the spare parts bag should fit it.I tried to remove the nozzle and can't get un Screwed any tips or tricks how to remove it

then of course, it's "Lefty Loosy, Righty Tighty". I always have to say that to myself in my head otherwise i try and turn it the wrong way - LOL

Similar threads

- Replies

- 2

- Views

- 99

- Replies

- 20

- Views

- 1,118