Hey all,

I have a 10 year old BRS DELUXE 6 stage RODI system. I added a second membrane for saving water a few years ago.

Recently, I moved to a house with amazing water pressure and got 2xmembranes 100GPD. so now I have 200GPD.

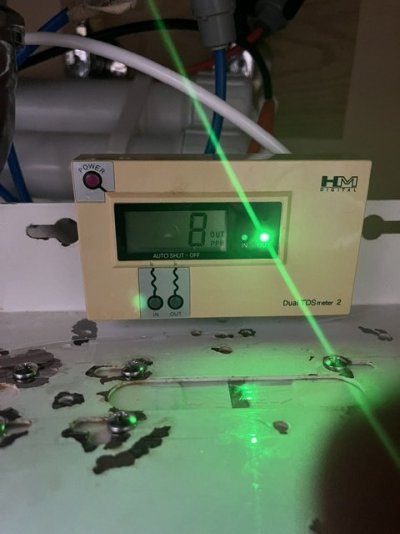

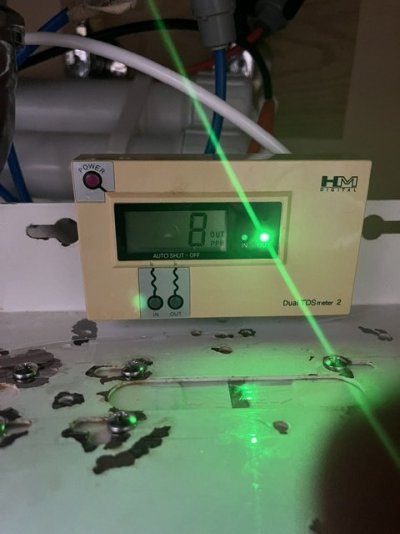

My TDS incoming from the city is 38. the water coming out of the DI Resin is 6 at the lowest. I have a HM D-2 Dual TDS Meter that came with the original purchase. It has never been recalibrated, but I don't think it needs to be?

The DI resin was packed by myself, so maybe that could be it? there is a lot of air in the DI Resin cartridges. about half. So I am not sure, some people say that shouldn't affect the results of the TDS.

I also tried this with a single membrane just to discard that possilibity that my flow isn;t what I believe. But alas, there is indeed wonderful water pressure here, so that is not a factor. I still couldn't get less than 8-6ppm TDS.

Everything is new but the cartridges themeselves.

1 x 1 Micron - 2.5" x 10" Sediment Filter - Neo-Pure

2 x BRS Universal Carbon Block Filter - 1 Micron

2 x One Cartridge Refill (1.25 lbs.) DI Resin

2 x 100GPD membranes

1 x 800ml flow restrictor/flush valve

I have a 10 year old BRS DELUXE 6 stage RODI system. I added a second membrane for saving water a few years ago.

Recently, I moved to a house with amazing water pressure and got 2xmembranes 100GPD. so now I have 200GPD.

My TDS incoming from the city is 38. the water coming out of the DI Resin is 6 at the lowest. I have a HM D-2 Dual TDS Meter that came with the original purchase. It has never been recalibrated, but I don't think it needs to be?

The DI resin was packed by myself, so maybe that could be it? there is a lot of air in the DI Resin cartridges. about half. So I am not sure, some people say that shouldn't affect the results of the TDS.

I also tried this with a single membrane just to discard that possilibity that my flow isn;t what I believe. But alas, there is indeed wonderful water pressure here, so that is not a factor. I still couldn't get less than 8-6ppm TDS.

Everything is new but the cartridges themeselves.

1 x 1 Micron - 2.5" x 10" Sediment Filter - Neo-Pure

2 x BRS Universal Carbon Block Filter - 1 Micron

2 x One Cartridge Refill (1.25 lbs.) DI Resin

2 x 100GPD membranes

1 x 800ml flow restrictor/flush valve

Last edited: