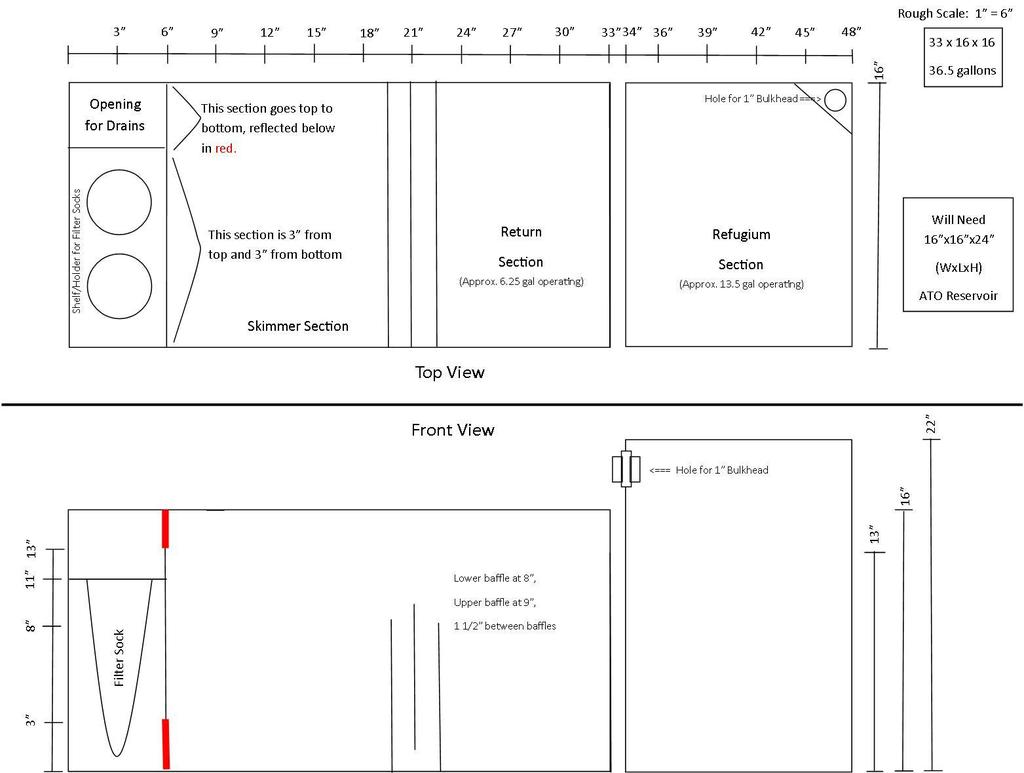

I'm not sure if these are your actual plans, but your ATO is 14x16x22. Not the 16x16x24 you quoted...Thanks for the response. With your permission, I'm attaching a crude design drawing of what I'm planning. It's a little different in that I'm separating the "sump" from the refugium, along with a stand-alone ATO reservoir (mentioned but not shown in the drawing). So in essence, I'm building three acrylic "items". The refugium will gravity feed back to the sump and be fed from the return manifold. As discussed earlier, I've ordered and received the 1/4" cast. As you will see, there are several baffles/walls that present a challenge for the pin method, which is why I asked the original question.

Your comments, even if it is to tell me I'm nuts, will be greatly appreciated. If someone else that's done something similar, please chime in as well. As an answer to Tom Cruise's question a long time ago...yes, I can handle the truth!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acrylic Fabrication Q & A

- Thread starter Turbo's Aquatics

- Start date

-

- Tags

- acrylic diy fabrication

- Tagged users None

dbl

It Takes Less Energy to be Nice

View Badges

Excellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

Reef Squad Emeritus

Hospitality Award

My Tank Thread

I'm not sure if these are your actual plans, but your ATO is 14x16x22. Not the 16x16x24 you quoted...

Thanks for the comment. The 14x16x22 compartment in my crude drawing is actually a detached refugium. The ATO mentioned is not actually on the drawing.

Laser cutting leaves an edge that is not useable for solvent welding. Not that you can't actually weld it, but you definitely shouldn't. Any heating is bad and can eventually (or in the case of laser cuts, will most likely immediately) cause crazing.

- Joined

- Aug 8, 2015

- Messages

- 1,454

- Reaction score

- 1,251

Yea Floyd What is your take on laser cut panels on 3/4'' stock for a 180 gal DT ??

I own a CO2 Laser CNC, and I can tell you without a doubt. DO NOT weld the edges that it cuts. You can look at them once and tell they are in no way flat or clean enough. Then there is the heat issue Bud discussed. You can cut them out oversize, then run them through a standard router table to clean them up. That works well and is quick, since the laser cutter makes sure all the panels are square and identical.

I have experienced the same with laser cutters. found its just as easy to cut with a table saw and route the edges. I do use a laser cutter for odd shaped that do not have to be welded.

Yea Floyd What is your take on laser cut panels on 3/4'' stock for a 180 gal DT ??

NEVER bond a laser cut edge. They will craze due to the internal stress the cut edge is put under from the heat of the laser. Lasers also do not cut at a 90 degree. They have a angled kerf due to the optical focusing of the beam. You should only bond a saw cut or machine routered edge.

I wouldn't recommend using a laser to cut a square either. If any mirror is slightly out of alignment, you will not get a perfect square. Have someone wit a cnc or good table saw cut them. Especially for 3/4" material and a display tank.

- Joined

- Aug 10, 2013

- Messages

- 132

- Reaction score

- 12

Hi floyd, I working on a 180gal 72" long tank. I have a question, how do you weld the top and bottom? Do you bond all 4 side at the same time? Get an assistant pulling the pin while you run the solvent? Thanks for your help ahead.

I'm glad someone just asked this. I was about to order some cut parts from Ponoko to make an ATO container. Not anymore! Is there somewhere online that you can order CNC cut pieces? We have an acrylic sponsor, don't we?

We do have a sponsor... Total Plastics.

https://www.reef2reef.com/threads/acrylic-fabrication-q-a.224773/page-2#post-2616407Hi floyd, I working on a 180gal 72" long tank. I have a question, how do you weld the top and bottom? Do you bond all 4 side at the same time? Get an assistant pulling the pin while you run the solvent? Thanks for your help ahead.

I'm going to follow up with "running the solvent" as some point to answer your other question. You only need to have a helper with really long joints, the 180 might be one of these. It would be more of another person running solvent, you start at one corner and meet at the other, then go back and pull pins. For long joints you would likely use the ultra-scary 16 gauge needle, which is actually ultra-awesome

- Joined

- Aug 10, 2013

- Messages

- 132

- Reaction score

- 12

Thank you floyd. I will ask my son to help me. We start from 1 corner and go opposite direction. Will let you know the result tomorrow. Thanks again

Just remember to watch for float when you pull the last pins. If you use the 16 gauge needle, use a 2 oz squeeze bottle 3/4 full. If you haven't used a 16 gauge before, find a couple pieces of scrap and give it a quick practice. If you're good with the smaller needles, you'll be good with the 16 gauge, it's all about touch, pressure, and speed. And not knocking pins out with the rigid needle. The solvent almost self-flows out of the bottle. You can do a 12' joint by yourself in less than 20 seconds

While I agree with Floyd on the methods he has outlined on this thread there is one area where we differ so far. The use of pins is the correct method for construction...however using the solvent recipe he provided I recommend a soak of the seam for about 60 seconds at least before pulling the pins. This gives adequate time for the solvent to attack both surfaces and avoid a splash and run when the pin is pulled. The area around the seam can develop a soaked blemish for lack of a better term if the solvent is allowed to pool outside of the actual seam area. If you allow the material to soak for too long the seam may start to dry out and require more solvent to prevent a bubbled seam. This is part of the art of acrylic fabrication to reduce the 'run' around the seam area. I pictured a fence system I use to remove the saw marks from the acrylic prior to bonding. This is a two flute solid carbide bit for acrylic purchased from FTM Plastics on the web. One pass is all that is needed per side. My saw is set up to over size the cuts to offset for the .200" taken off by the router. The fence is made of .472" cell cast acrylic and has been in use for 30 plus years. It replaced a Jet joiner with carbide blades at one tenth of the cost. Works great and can be adjusted for various bit sizes.

I know exactly what you are talking about w/r to the soaked blemish. The solvent that oozes out, if thin enough and there is enough of it, partially "attacks" the acrylic panels (the fillet surface area) and leaves a little tiny bit of crazing behind. I notice this on smaller builds sometimes. On larger builds, top and bottom seams, I probably end up having close to 60s of soak time once I get all the pins pulled so that makes sense. I'll have to try this next time I do a tank build, usually 30s works pretty well. In fact I think James/Envision recommends no more than 45 seconds but I can't recall why exactly.

- Joined

- Aug 10, 2013

- Messages

- 132

- Reaction score

- 12

I ended up not using 16g pin, i used 20g instead but i inserted more pins with a gap around 5". My son and i was successfully weld the bottom with very little or no bubble at all.

Thanks Floyd

Here is the pic of the seam

Thanks Floyd

Here is the pic of the seam

I was referring to the needle, the one used for the applicator bottle, not the pins. The 16 gauge needle for the solvent applicator is really large and the solvent flows very quickly out of it. For the pins, I use 28 gauge picture hanger wire. But I'm glad it turned out!!I ended up not using 16g pin, i used 20g instead but i inserted more pins with a gap around 5"

You wouldn't want to use a compound, that would contaminate the water. They do make something you can attach to magnet algae removers that will remove scratches. Our LFS uses one on their 1200g tank

dbl

It Takes Less Energy to be Nice

View Badges

Excellence Award

Reef Tank 365

Article Contributor

Moderator Emeritus

Reef Squad Emeritus

Hospitality Award

My Tank Thread

@Floyd R Turbo...ordered and received my Weldon 4. However, I ended up with two different types. One say 4 and one says 4SC. Do you know if there is a difference? And if so, should I just return the SC version? Thanks in advanced.

Similar threads

- Replies

- 5

- Views

- 109