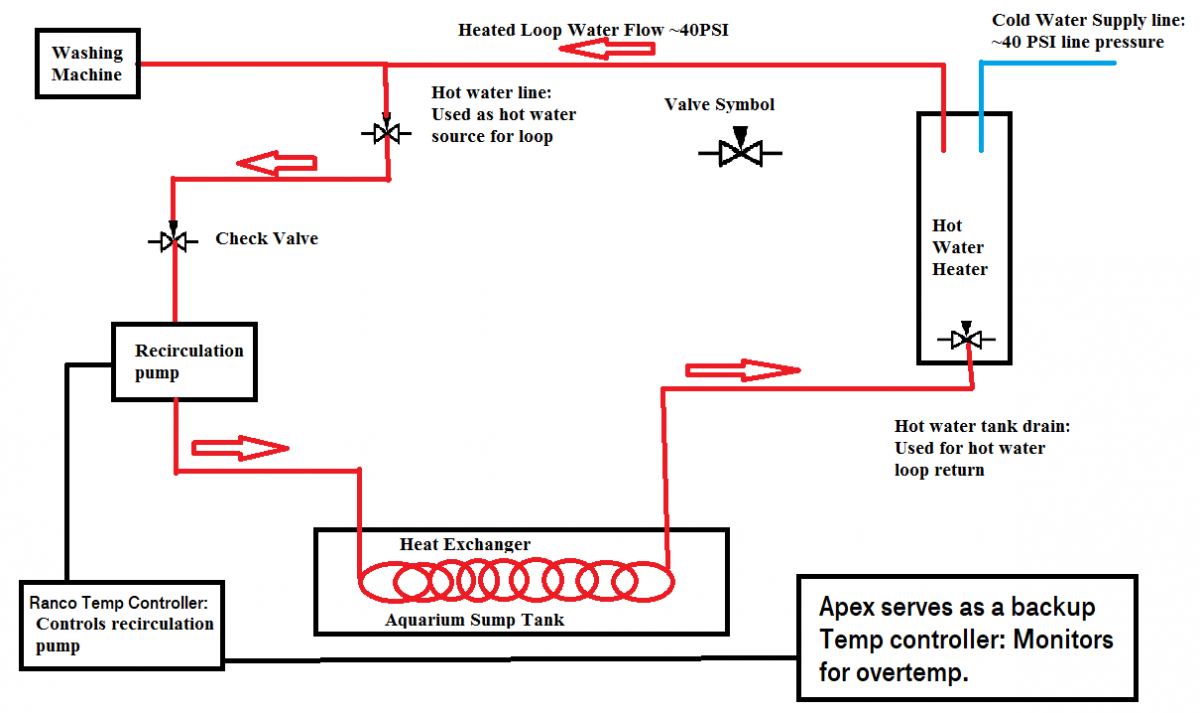

Yes this is the biggest electricity saver I ever implemented.This is a diagram of my radiant heating system for the main system. If I ever add a second loop to the system for water changes I will have a PEX coil in one of my water storage tanks. This is by far the most efficient and safe way I have ever heating my aquariums. There is no concern about the heat exchanger coil not being submerged as it can't overheat. I looked at inline heaters but for the cost of a good one I can basically pay for a replacement hot water heater.

I have a very similar heater setup that's been running flawlessly for a couple years now. I use a coil of pex in the sump for the heat exchanger. I like SSRs (solid state relays) to do the pump switching, they basically last forever. I've just never been able to trust mechanical relays for my heater switching, they just wear out eventually. I use a PID unit to control the SSR. I've got my Apex as a backup saftey/kill switch just as you have it.