Might want to upsize it to 2". What is the flow rate on the pump?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another Flood

- Thread starter bdesign

- Start date

- Tagged users None

How full do you normally keep those barrels? 75%? Or 90%?

I’d guess 80-90% because it gets dicey when refilling the DT and I’ve ran out before... not a good time.

Might want to upsize it to 2". What is the flow rate on the pump?

I don’t recall the exact flow rate. It’s pretty high though, it needs to push 15ft. up before the 90 degree turn toward the DT (and then 90 deg down).

EDIT:

- Max Head- 39' MAX HEAD

- Flow - 1750gph @ 0'

- In - 1" MPT

- Out - 1" MPT

Might want to upsize it to 2". What is the flow rate on the pump?

If you keep the barrels that full i would definitely go as big as I could where finding a larger uniseal is practical. If they sell 3 inch and getting it is easy.. hell.. why not. Only a couple feet of pipe. Question is that large of a uniseal on a rounded container. I dont know the specs of such a large uniseal and how they work on a barrel. Never used such a large one before.

- Joined

- May 16, 2020

- Messages

- 526

- Reaction score

- 1,208

Is the right bucket pvc a shorter distance to the top bulkhead, like from where it splits? Perhaps the right bucket is getting more water that way. Doesn’t explain why it worked for awhile tho.Help

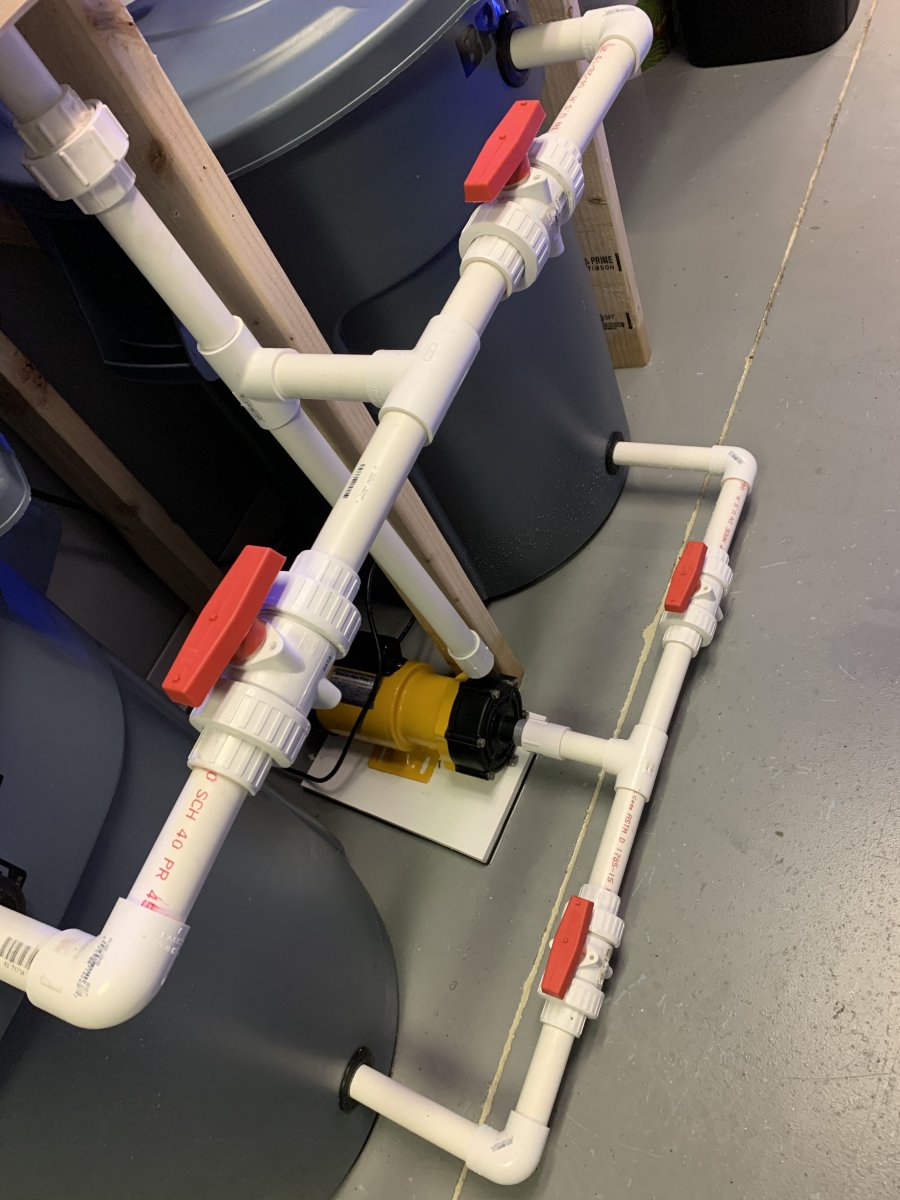

I can’t seem to figure out what is causing the Water Mixing Station to flood/overflow.

It’s a very simple setup.

With all four valves fully open, the pump pulls from the bottom of both containers and then returns back into them both.

I have a timer set up for twice-a-day mixing/circulation and it’s worked flawlessly for a long time.

And then it didn’t.

I have been surprised with 30 gallons of water on the floor more than once.

I fiddled with closing down the valve returning into the right container and found a level of closure that seems to work and hasn’t been allowing it to overflow.

Until today.... I’ve come to the office, once again, to find gallons of water flooding onto the floor due to the right container overfilling - even with the return into that container partially closed.

I’ve removed all four Ball Valves and checked their operation as well as checked the pipes for an obstruction.

The valves look to be working properly and all pipes are clear.

Any ideas from sharper than mine?

Is the right bucket pvc a shorter distance to the top bulkhead, like from where it splits? Perhaps the right bucket is getting more water that way. Doesn’t explain why it worked for awhile tho.

Nope

Everything is “exactly” symmetrical.

- Joined

- Jan 3, 2018

- Messages

- 829

- Reaction score

- 697

I would increase the suction line to 1-1/2 or 2" rather than the return - or add a second large diameter balance line between the tanks. The 1" suction lines are really to small for that pump considering you are relying on it to balance the levels. There is probably so much pressure drop in the suction line and small differences in resistance create an imbalance in how much water is being drawn from each tank. This can easily produce several inches of level difference between the tanks. The large diameter balance line at the bottom will assure the tanks are equalized in level.

- Joined

- Nov 11, 2017

- Messages

- 295

- Reaction score

- 193

How far down does your RODI pipe go into the right barrel? Do you ever notice air bubbles going into the RODI barrel when you open the valve? I wonder if the water level is being changed by air that is caught in the RODI pipe?

Do you have float valves in the barrels to turn off the pump when the water level gets too high?

Do you have float valves in the barrels to turn off the pump when the water level gets too high?

I would increase the suction line to 1-1/2 or 2" rather than the return - or add a second large diameter balance line between the tanks. The 1" suction lines are really to small for that pump considering you are relying on it to balance the levels. There is probably so much pressure drop in the suction line and small differences in resistance create an imbalance in how much water is being drawn from each tank. This can easily produce several inches of level difference between the tanks. The large diameter balance line at the bottom will assure the tanks are equalized in level.

All lines are 1 1/2"D - I used a threaded upsize adapter at the pump.

How far down does your RODI pipe go into the right barrel? Do you ever notice air bubbles going into the RODI barrel when you open the valve? I wonder if the water level is being changed by air that is caught in the RODI pipe?

Do you have float valves in the barrels to turn off the pump when the water level gets too high?

The RO/DI pipe is about 6" above the top of the right barrel so that I can easily remove/replace the lid.

I don't have float valves in those barrels... that's an idea is the 3" joining pipe between the two containers doesn't correct the flooding.

Similar threads

- Replies

- 188

- Views

- 3,879

- Replies

- 4

- Views

- 173

- Replies

- 10

- Views

- 234

- Replies

- 3

- Views

- 141

- Replies

- 10

- Views

- 206