Help

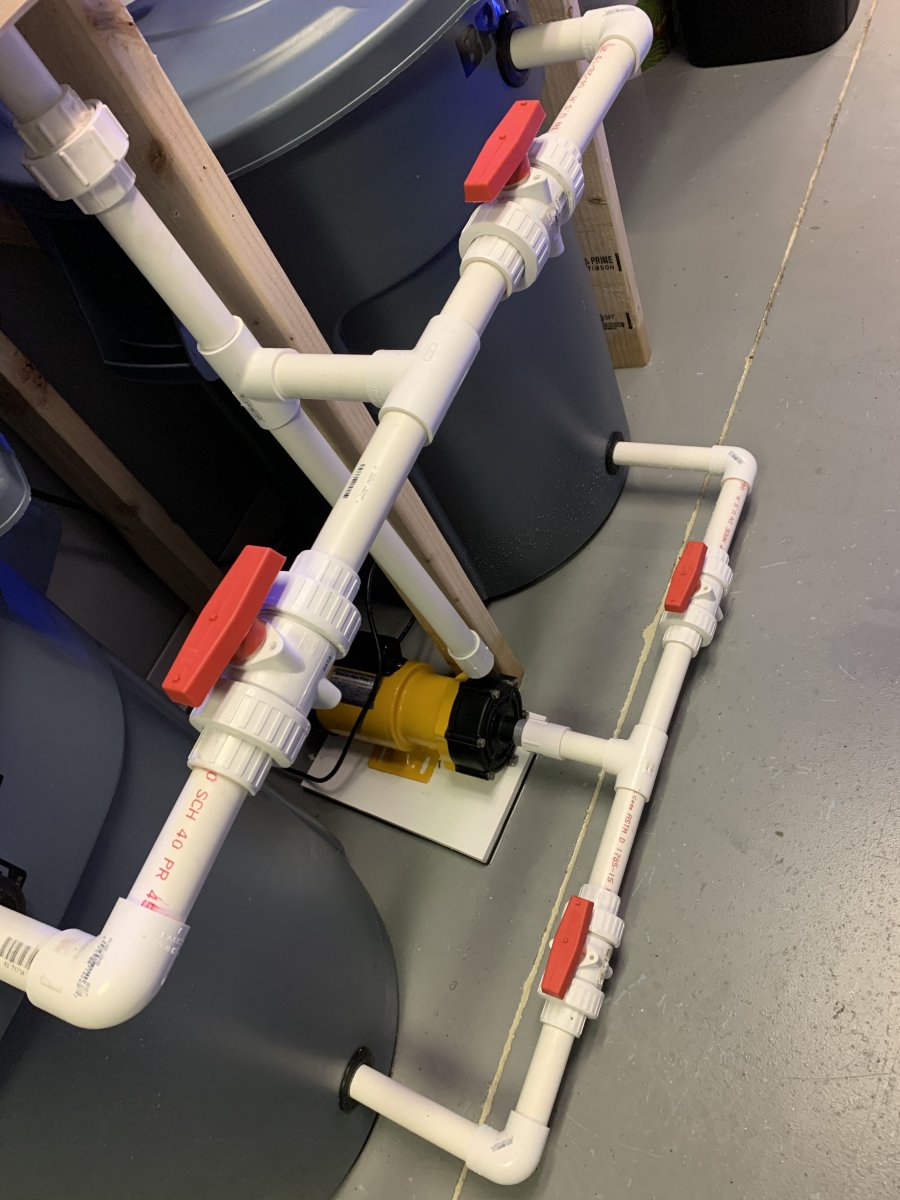

I can’t seem to figure out what is causing the Water Mixing Station to flood/overflow.

It’s a very simple setup.

With all four valves fully open, the pump pulls from the bottom of both containers and then returns back into them both.

I have a timer set up for twice-a-day mixing/circulation and it’s worked flawlessly for a long time.

And then it didn’t.

I have been surprised with 30 gallons of water on the floor more than once.

I fiddled with closing down the valve returning into the right container and found a level of closure that seems to work and hasn’t been allowing it to overflow.

Until today.... I’ve come to the office, once again, to find gallons of water flooding onto the floor due to the right container overfilling - even with the return into that container partially closed.

I’ve removed all four Ball Valves and checked their operation as well as checked the pipes for an obstruction.

The valves look to be working properly and all pipes are clear.

Any ideas from sharper than mine?

I can’t seem to figure out what is causing the Water Mixing Station to flood/overflow.

It’s a very simple setup.

With all four valves fully open, the pump pulls from the bottom of both containers and then returns back into them both.

I have a timer set up for twice-a-day mixing/circulation and it’s worked flawlessly for a long time.

And then it didn’t.

I have been surprised with 30 gallons of water on the floor more than once.

I fiddled with closing down the valve returning into the right container and found a level of closure that seems to work and hasn’t been allowing it to overflow.

Until today.... I’ve come to the office, once again, to find gallons of water flooding onto the floor due to the right container overfilling - even with the return into that container partially closed.

I’ve removed all four Ball Valves and checked their operation as well as checked the pipes for an obstruction.

The valves look to be working properly and all pipes are clear.

Any ideas from sharper than mine?