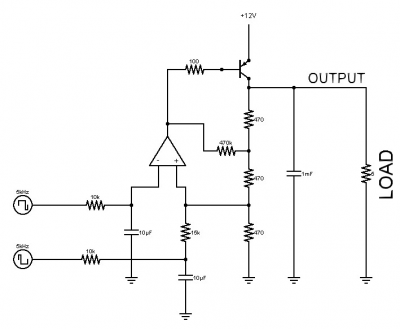

Here is a link to Digikey's explanation on BLDC motor control using back EMF. From what I've seen of the Chinese controllers, they use a 3 phase inverter bridge, characterized by the use of 6 power mosfets. This is also how the Maxspect gyre controller operates. The only issue with using a back EMF controller is tuning the circuit to the motor. TI has a very nice in depth how-to for tuning the controller for their chips. You might be able to glean some useful information off this how-to when tuning for the Chinese controllers.

TI Tuning Spec:

https://www.digikey.com/en/articles...ntrolling-sensorless-bldc-motors-via-back-emf

TI Tuning Spec:

https://www.digikey.com/en/articles...ntrolling-sensorless-bldc-motors-via-back-emf