Everything looks great....I love the OCD in reefers! I’m sure my system is going to be the same way. I build all my own stuff and take my time to make it right. Good luck, I’ll be following along on this one!!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Centerline's RedSea Reefer 525 XL +25 +25 Build

- Build Thread

- Thread starter Centerline

- Start date

- Tagged users None

Ain't hard plumbing fun? Looking good though.

Ya Man, only issue with being OCD is once your done you have to rethink it allEverything looks great....I love the OCD in reefers! I’m sure my system is going to be the same way. I build all my own stuff and take my time to make it right. Good luck, I’ll be following along on this one!!

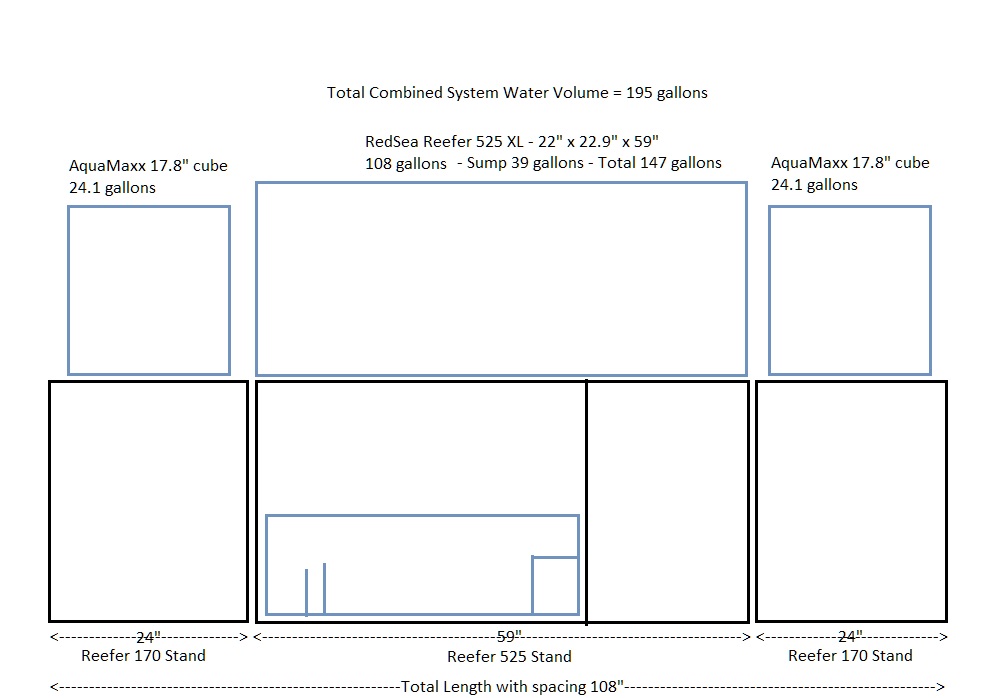

For those of you who don't know exactly what the heck if going on with this tank I did a quick diagram of the basic layout. Ill do one for the plumbing shorty.

Worst thing is crawling through the cutouts I made in the side stands to get to the plumbing behind them. The tile is killing my knees LOL.Ain't hard plumbing fun? Looking good though.

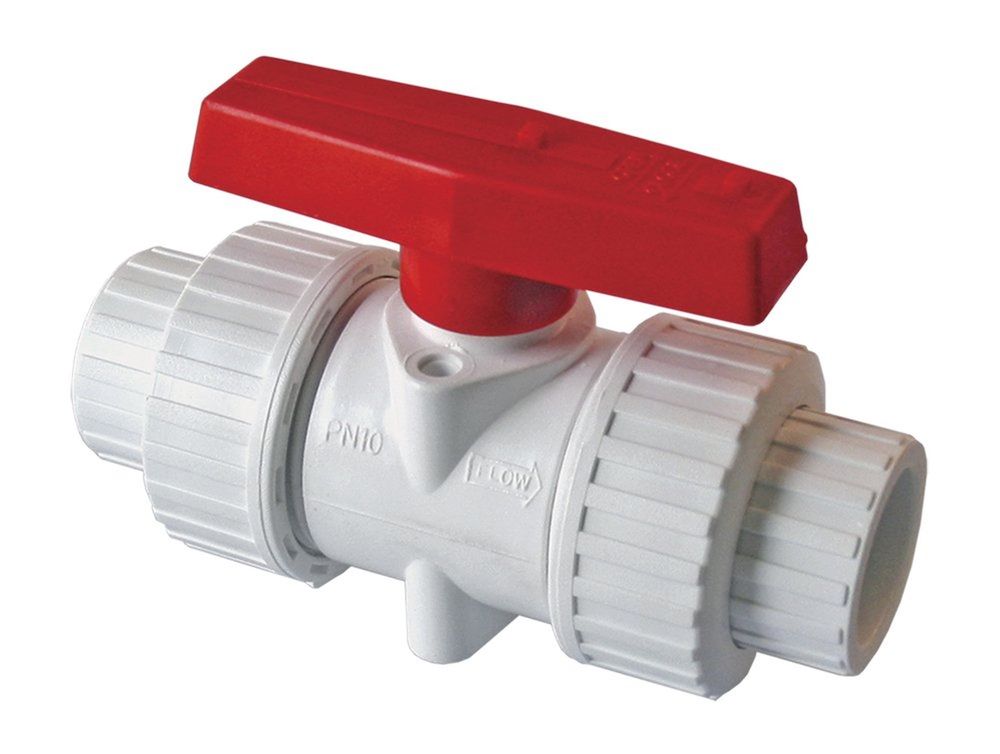

Last night I finished the last little bit of plumbing for the tank. I also pulled all the valves ( American Value brand - $15.00 on amazon - ironically says made in China on the side lol) apart to add silicone lube and worked them till they were turning as smooth as butter. I have used these before on other tank projects and love them. You can completely break them down for cleaning or replacement, they turn very easily if you take the time to pull them apart and lube them and they come with pre drilled mounting holes if needed. I feel they work as well as any gate valve I have used for fine tuning. I know a lot of people like the valves that come with the Reefer tanks but I personally find them to be a little hard to work with / tune.

https://www.amazon.com/American-Val...=8-1&keywords=american+valve+union+ball+valve

And here is what the tank looks like from behind.

The two smaller tanks are connected via unions to make it easier to disassemble and move to the wall / shim. Seems like it should be easy - likely will not be

https://www.amazon.com/American-Val...=8-1&keywords=american+valve+union+ball+valve

And here is what the tank looks like from behind.

The two smaller tanks are connected via unions to make it easier to disassemble and move to the wall / shim. Seems like it should be easy - likely will not be

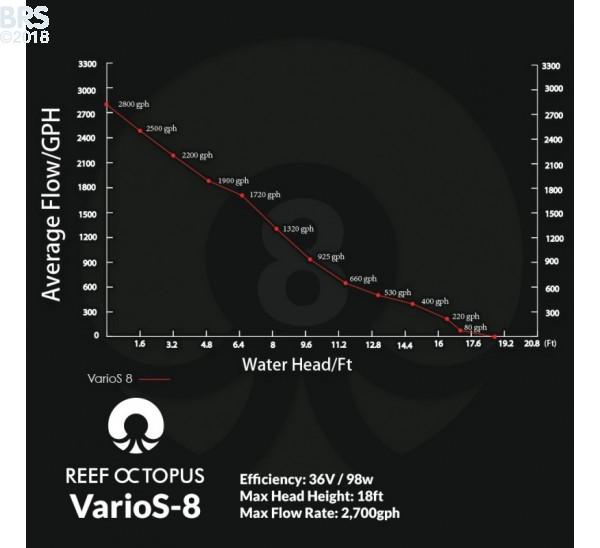

Did the water test on the 525 and one of the 25s tonight. So far so good - no leaks or anything crazy happening. One thing I learned is that the return pump, a Varios S8 is capable of running a much larger system - may have been a little overkill!

One thing I learned is that the return pump, a Varios S8 is capable of running a much larger system - may have been a little overkill!

Better caught late than never! How'd you initially miss the size of the pump? (2700 GPH!)

Are you gonna switch to something more sensible, or keep it?

No, Ill stick with the Varios. I can run it at 50% and silently get a turn over in all tanks of about 8 times an hour. Its nice how quit the thing is.Better caught late than never! How'd you initially miss the size of the pump? (2700 GPH!)

Are you gonna switch to something more sensible, or keep it?

A lesson I seem destined to learn over and over in life is "haste makes waste". Below shows the back of one of the 25s blown out because I was rushing around trying to get all three tanks positioned against the wall and didn't notice that the tank below had a plumbing fitting stuck on the side of the 525. Rather than pay $170 for a new tank I picked up a new pane of glass from a local company ($21) and repaired it.

To get the broken glass off I used braided fishing line (I have a lot of it around) to cut the silicone. Very easy to do.

Next I cleaned all the old silicone off the other glass panes. Cleaning silicone of glass panes is a straight pain - pun obviously intended - it took a at least an hour. I then taped all the glass and siliconed in the new glass.

I would like to say lesson learned but Ill hold that until everything is in place, no leaks and cycling.

To get the broken glass off I used braided fishing line (I have a lot of it around) to cut the silicone. Very easy to do.

Next I cleaned all the old silicone off the other glass panes. Cleaning silicone of glass panes is a straight pain - pun obviously intended - it took a at least an hour. I then taped all the glass and siliconed in the new glass.

I would like to say lesson learned but Ill hold that until everything is in place, no leaks and cycling.

No, Ill stick with the Varios. I can run it at 50% and silently get a turn over in all tanks of about 8 times an hour. Its nice how quit the thing is.

I will be a little surprised if you can actually get that kind of flow rate through the amount of plumbing you have set up.

A quick calculation on friction loss seems to indicate about +11 feet on top of actual head pressure.

That would yield more like 600 or 700 gallons per hour total from that pump with this plumbing.

You'd really like 1.25 or 1.5" plumbing for the flow rate you stated up there...even 1.25" will add on almost +4 feet of head pressure at that flow rate.

Are the outlets in to the tiny tanks also 1 inch or are they smaller?

And I guesstimated 20 feet of total plumbing length in your system. Do you think that's about right or is it actually more or actually less? Give me a number if you think it's different. Also, how many 90's, Tee's and ball valves total?

I will be a little surprised if you can actually get that kind of flow rate through the amount of plumbing you have set up.

A quick calculation on friction loss seems to indicate about +11 feet on top of actual head pressure.

That would yield more like 600 or 700 gallons per hour total from that pump with this plumbing.

You'd really like 1.25 or 1.5" plumbing for the flow rate you stated up there...even 1.25" will add on almost +4 feet of head pressure at that flow rate.

Are the outlets in to the tiny tanks also 1 inch or are they smaller?

And I guesstimated 20 feet of total plumbing length in your system. Do you think that's about right or is it actually more or actually less? Give me a number if you think it's different. Also, how many 90's, Tee's and ball valves total?

Thanks for the help Man! Honestly I just don't know how much plumbing I'm using here. Ya, most everything is 1" including up to the returns (teed down to half inch) on the 25s. I think I have 3 Ls and 1 T and 1 ball valve on each of the 25s. Honestly though I am probably wrong. Ill grab a picture of the manifolds on the 25s and the back of the reefer when I get home, pull out a tape measure, document and post. I hope this pump does the trick though and it SEEMED like it was doing fine during my leak test but that all subjective until I put a flow meter on it. On the main display anywhere around 5x return will keep me happy. On the little ones I need to be a bit more precise with the flow rate as I have a few experiments I would like to run that will require equal flow rates. I do have a backup plan if needed but would rather do it all from one pump.

I COULD just redo it all with 1.5" though. Not really that big of a deal now that I have already done it twice

Last edited:

Honestly though I am probably wrong. Ill grab a picture of the manifolds on the 25s and the back of the reefer when I get home, pull out a tape measure, document and post.

Right on. So we'll get some closer estimates.

Just going by your guesstimate (at least as good as mine!) that would put added head pressure due to friction at +13 feet.

On the main display anywhere around 5x return will keep me happy.

If you only need 5x at the tank, I think that's closer to the ideal range for the plumbing you have.

On the little ones I need to be a bit more precise with the flow rate as I have a few experiments I would like to run that will require equal flow rates. I do have a backup plan if needed but would rather do it all from one pump.

I can't really argue against seeing for yourself since experience is always valuable.

But if it were me and I had that requirement, I would have the smaller tanks on their own pump....or even set each one up with it's own return. Balancing from one flow source has the potential to be a pain since every flow change you make affects all the other tanks connected every time.

But if it were me and I had that requirement, I would have the smaller tanks on their own pump....or even set each one up with it's own return. Balancing from one flow source has the potential to be a pain since every flow change you make affects all the other tanks connected every time.

No truer words... it took me at least two hours to get them all to work together with minimal drain noise during the leak test - it certainly encouraged me to consider gate valves for the 25s. At that time thought that it might be a good idea to remove them from the main return manifold and put them on their own pump. I do happen to have another S8 and considered something like this. Or I could use the S6 that I have designated for water changes and the chiller.

All I would really need to do is make a couple of new manifolds - I have spare valve parts so not a bunch of work.

So with respect to the amount of plumbing - you pretty much nailed it. 18 ft of return plumbing. I could trim that down to 11-12 as I ran the pipe to the right hand tank around the stand opening to avoid seeing it as much as possible. In retrospect the design was unnecessary because Ill have a drawer mounted in that cabinet anyway. So removing the extra pipe looks like the way to go.

There are 17 L fittings between all of the returns and the manifold as well as two Ts.

The 25s are split reduced to half inch and split off 1" pipe with only one valve on the left hand tank to isolate it for QT if needed.

With respect to the amount of turn over in the sump I'm not too concerned with the reefer - the tank has two Gyrers for in tank flow - more than enough. Dwell time with the skimmer is a good thing so no problems there. But if I cant get a solid 5x out of the 25s along with the main tank Ill have to do something about the manifold and superfluous pipe.

A while back @mcarroll correctly pointed out that I may have miscalculated the amount of turnover I was able to get with the amount of pipe and fittings I had going. My goal was to have at least 5x turnover from the tanks to sump. After taking the time to document I concluded that I needed to redesign some of the plumbing work if my goal of 5x turnover and a fairly quiet system was going to be realistic. It took a couple of weeks to find the time to implement the redesign but here is the final product. I still need to complete the rock work for the main tank but things are coming together.

Good eye. Yup - use it all the time.Now that is a Display! ...Hey is that a Harting turret lathe. wish i still had mine.

Thanks Man, should have the rock work done shortly and then a week or so to cure outside (epoxy & fiber glass).This is an awesome build! Can't wait to see it in full action.

Similar threads

- Replies

- 3

- Views

- 468