redfishbluefish

Stay Positive, Stay Productive

View Badges

Staff member

Super Moderator

Reef Squad

Partner Member 2024

Excellence Award

Article Contributor

NJRC Member

Hospitality Award

My Tank Thread

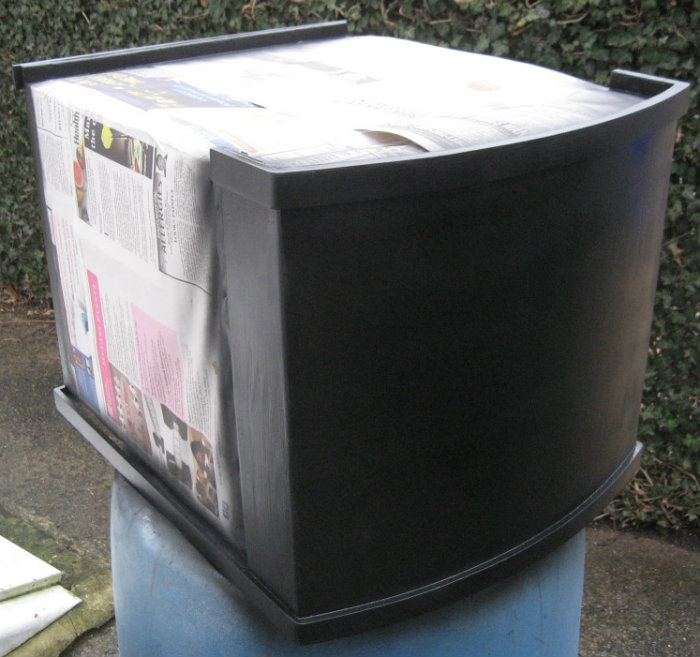

This DIY will be a work-in-progress. I don’t know if this build will work, so it could be a documented failure. I am starting this on January 7, 2013, and will update as I am permitted to spend a little free time in the shop without the boss screaming.

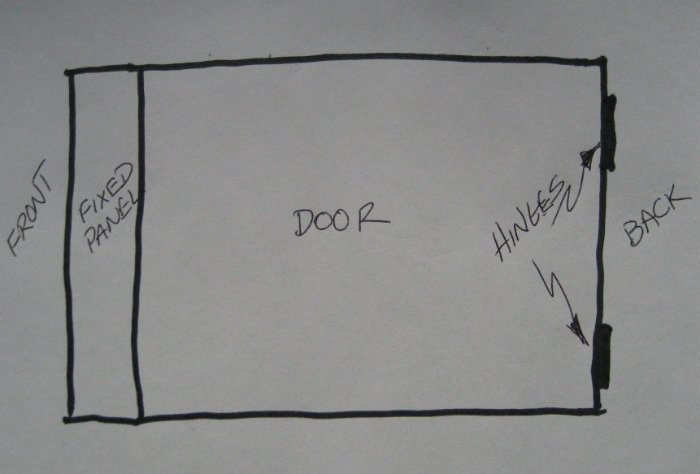

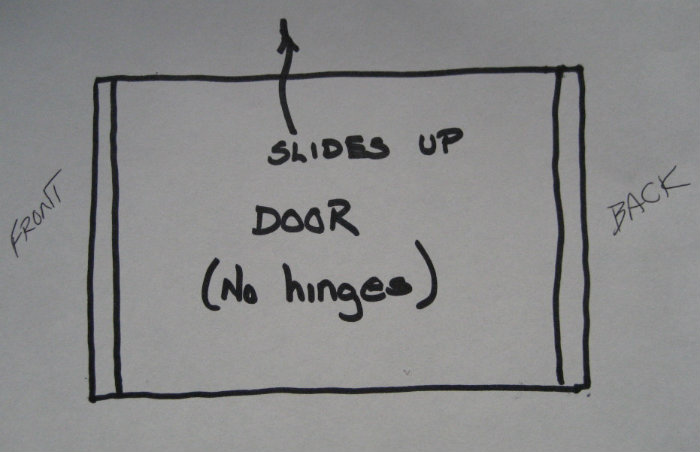

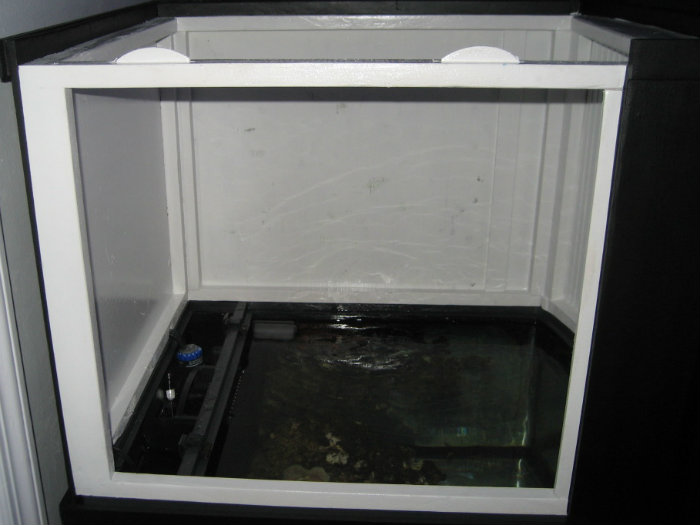

I am going to attempt to build a canopy for a nano cube. In particular a JBJ 28. However, this could be done with any nano cube by adjusting the dimensions. I’m actually not going to give dimensions, because I fit every piece and mark with a pencil.

The reason I’m doing this is twofold. The primary reason is that I would like to switch to LEDs, and I find the JBJ hood and any retro kits to be too costly, so I’m considering one of those dimmable Chinese jobs for around $170. The second reason is that I snapped one of the hinge pieces, and in attempting to change it by unscrewing those miniature screws, both of those screws, which were well rusted, snapped off.

The main use of materials will be inexpensive fir strips (ca 2 ½†x 5/8â€) for the carcass and ¼ plywood for the skin.

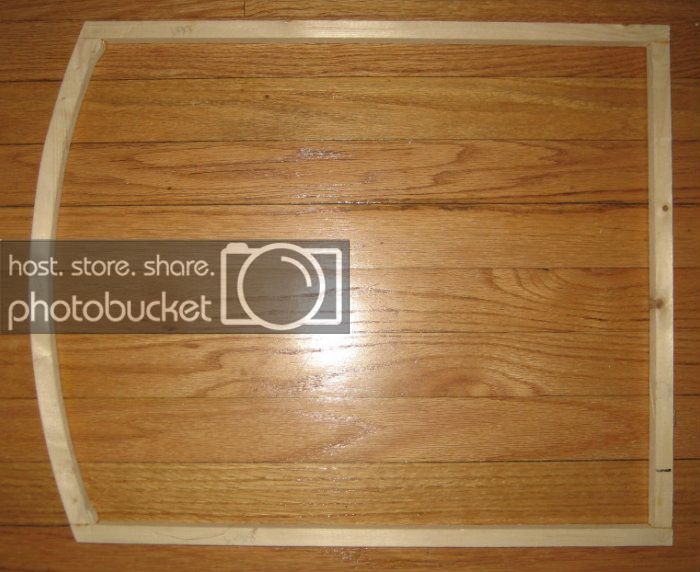

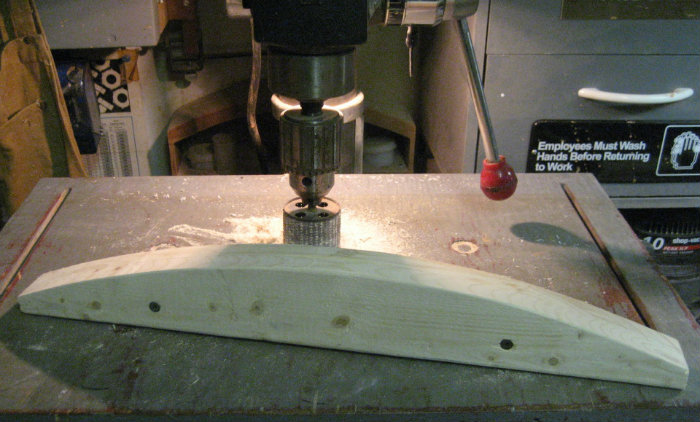

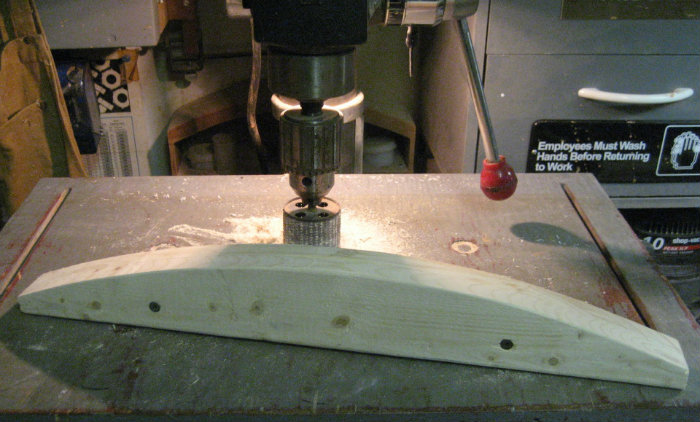

The first thing I did was to trace the front arch of the tank on a piece of fir strip, screwed this to a second piece, and cut that out on the band saw. I know not everyone has a band saw, so a saber saw or coping saw could be used. I cut the line “fat†and then used a power rasp to bring it to the line (Hand rasping or a belt sander would work as well):

One of these pieces will be the top front brace and the other the lower front brace of the carcass.

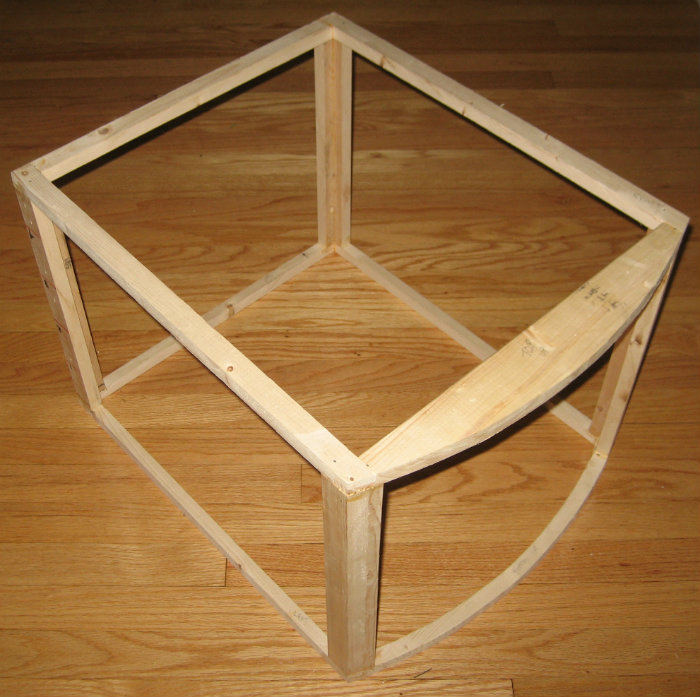

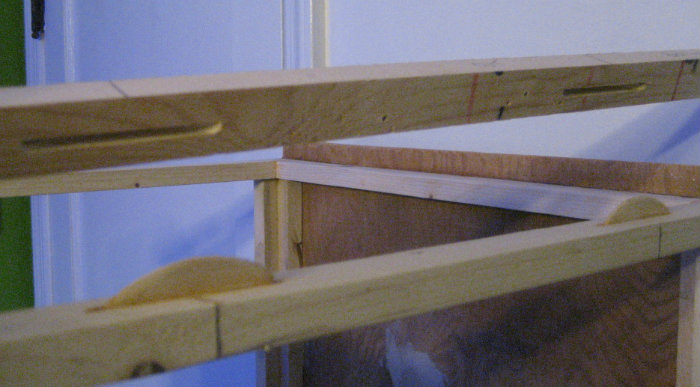

Next were the side and back brace pieces. The lower pieces I ripped at 5/8†wide while the upper pieces were ripped at 1 inch wide. The 5/8 pieces will nicely fit on the frame of the nano, while I wanted a little more meat on the upper pieces…..I tend to over-build.

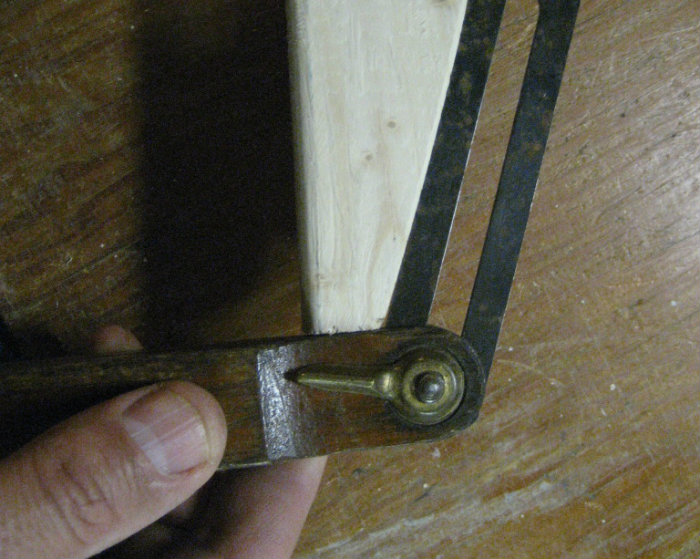

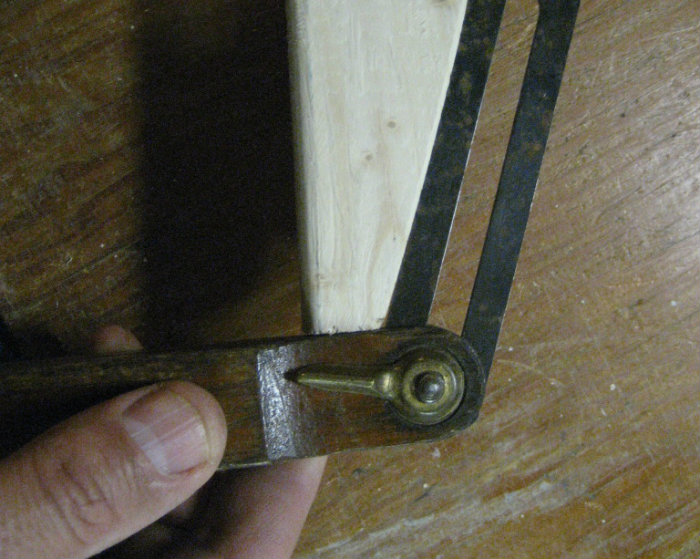

For the upright supports, I made L-brackets by ripping the fir stripping. With the front uprights, I first determined the angle at the corners so that I could adjust the angle of the saw:

The boards were ripped, glued (waterproof glue), and nailed. The 90o L brackets will be for the two back uprights, while the angled ones go up front. I will throw this one number at you…..I’m looking to make this canopy about 16-17 inches high, so these L-brackets are 16 inches right now.

More to come…..

I am going to attempt to build a canopy for a nano cube. In particular a JBJ 28. However, this could be done with any nano cube by adjusting the dimensions. I’m actually not going to give dimensions, because I fit every piece and mark with a pencil.

The reason I’m doing this is twofold. The primary reason is that I would like to switch to LEDs, and I find the JBJ hood and any retro kits to be too costly, so I’m considering one of those dimmable Chinese jobs for around $170. The second reason is that I snapped one of the hinge pieces, and in attempting to change it by unscrewing those miniature screws, both of those screws, which were well rusted, snapped off.

The main use of materials will be inexpensive fir strips (ca 2 ½†x 5/8â€) for the carcass and ¼ plywood for the skin.

The first thing I did was to trace the front arch of the tank on a piece of fir strip, screwed this to a second piece, and cut that out on the band saw. I know not everyone has a band saw, so a saber saw or coping saw could be used. I cut the line “fat†and then used a power rasp to bring it to the line (Hand rasping or a belt sander would work as well):

One of these pieces will be the top front brace and the other the lower front brace of the carcass.

Next were the side and back brace pieces. The lower pieces I ripped at 5/8†wide while the upper pieces were ripped at 1 inch wide. The 5/8 pieces will nicely fit on the frame of the nano, while I wanted a little more meat on the upper pieces…..I tend to over-build.

For the upright supports, I made L-brackets by ripping the fir stripping. With the front uprights, I first determined the angle at the corners so that I could adjust the angle of the saw:

The boards were ripped, glued (waterproof glue), and nailed. The 90o L brackets will be for the two back uprights, while the angled ones go up front. I will throw this one number at you…..I’m looking to make this canopy about 16-17 inches high, so these L-brackets are 16 inches right now.

More to come…..