- Joined

- Jan 25, 2017

- Messages

- 19

- Reaction score

- 12

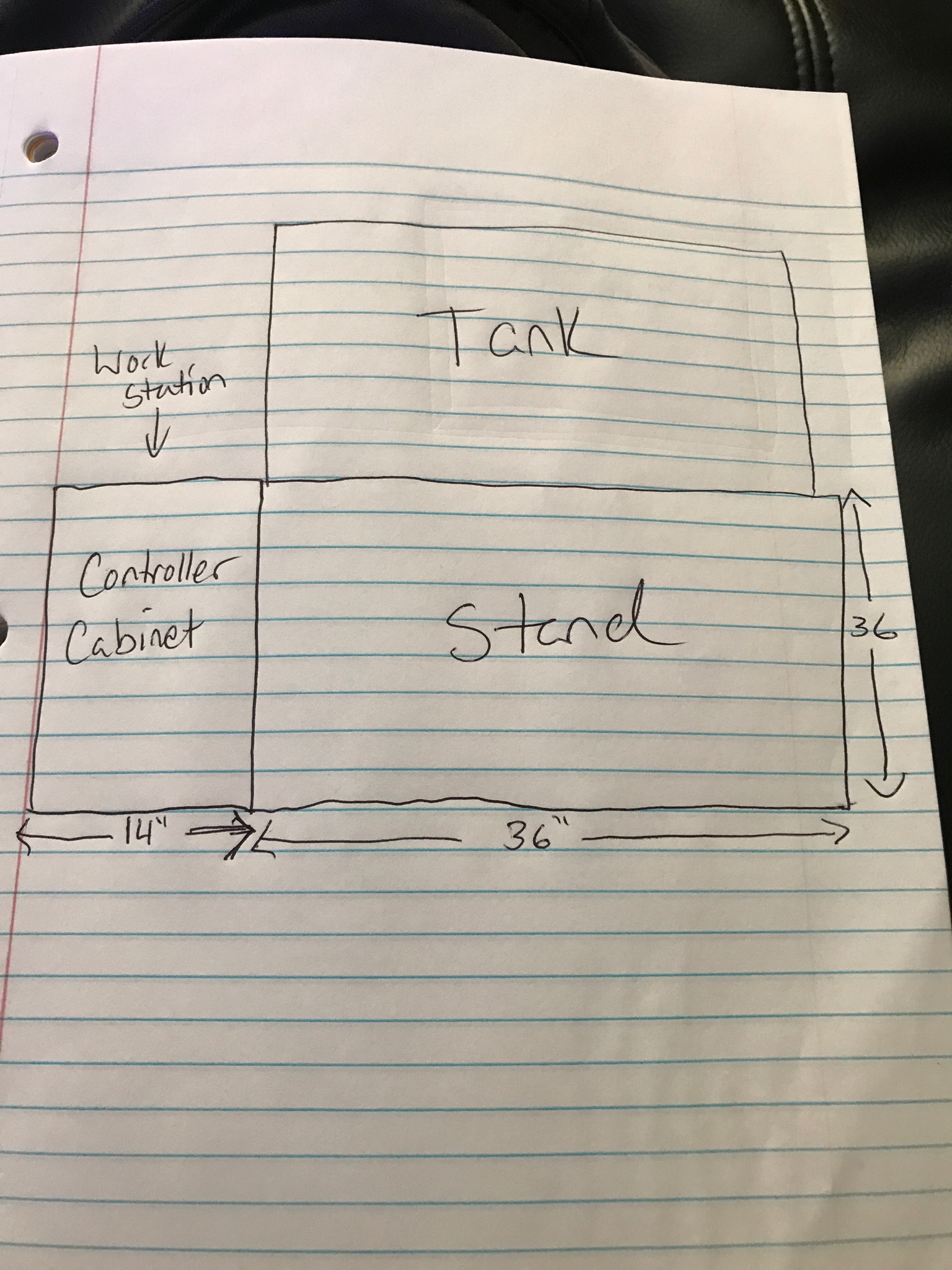

That really depends on how trusted they are. If it just has a little Tristan that will straightened out when you put the top on then you will be ok, if you want build them up like what you did to your center, if I remember right, you have a couple there. Make sure it will still be square. If you want to feel more at ease, there is a formula you can look up that tells you how to figure out how many psi a 2x4 can withstand, I forget where I found itI'm noticing now that 2 of my larger 2x4s going vertical are slightly twisted so the top won't fit smoothly. Is it wise to replace these boards or will it be okay once everything is screwed in together??