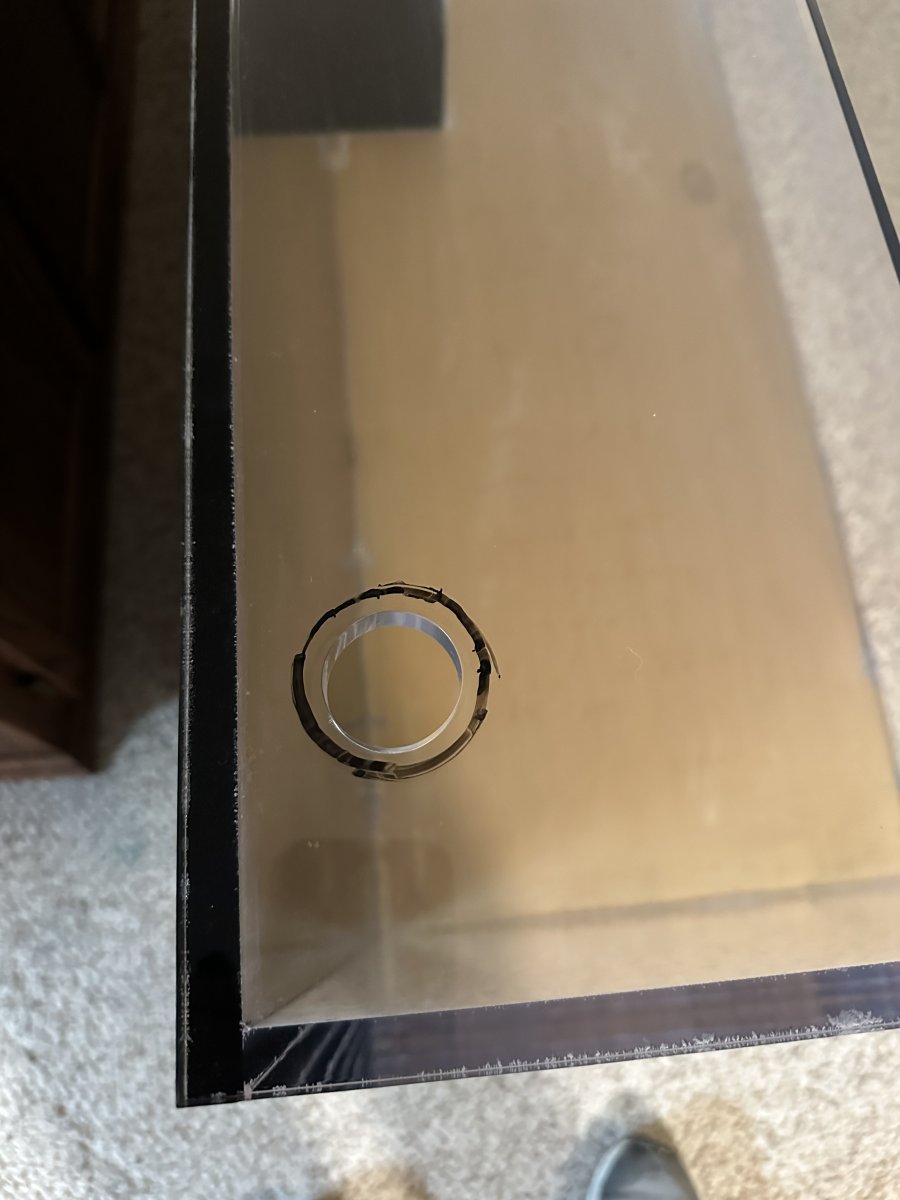

Working on setting up my 300gal tank and the previous owner ran a wet/dry sump so his return lines were only 1/2”. I am going with a traditional sump and running two ecotech m2’s. Acrylic is 1/2” thick and I have read the rule of thumb is 1.5x diameter of hole away from edge but with the previous holes being where they are will I have any issues over drilling them? I am planning on using a piece of 1x as a guide for the hole saw. I’ve seen people recommend using a router but I don’t own one and don’t think this tank is a good first time attempt if I were to buy one. Anyone offer any feedback on if I’ll have issues with the new hole in the picture below? I have 6 holes to drill out across the top

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drilling larger return hole

- Thread starter nate167

- Start date

- Tagged users None

If your able to secure a guide, set the guid hole as close to the closest edge of the hole vs centered.

Is there any min distance from the edge of that hole I should do? Ie 1/8” from the edge of the hole to get a clean new cut? Also drain tubes are 1.5” those should be good or do I need to enlarge those as well?If you’re able to secure a guide, set the guid hole as close to the closest edge of the hole vs centered. Is there any min distance from the edge of that hole I should do? Ie 1/8” from the edge of the hole to get a clean new cut?

The 1x+ rule is for glass. Acrylic is fine to drill near edges where top meets side wall, but leave some space between the hole and the cutouts, especially in corners, and also between holes.

Router is definitely easiest and best (are you sure you can't get one? ), but if you have to use a hole saw, I'd clamp some ply under the hole so the guide has something to work with. Make sure to keep the bit cool and don't stop with the saw in the cut.

), but if you have to use a hole saw, I'd clamp some ply under the hole so the guide has something to work with. Make sure to keep the bit cool and don't stop with the saw in the cut.

Router is definitely easiest and best (are you sure you can't get one?

Getting the router isn’t an issue…I’ve just haven’t used one since high school woodshop which was over 20 years ago. Is the router pretty user friendly with acrylic? I’m comfortable with woodworking regarding saws and whatnot just never had a need for a router.The 1x+ rule is for glass. Acrylic is fine to drill near edges where top meets side wall, but leave some space between the hole and the cutouts, especially in corners, and also between holes.

Router is definitely easiest and best (are you sure you can't get one?), but if you have to use a hole saw, I'd clamp some ply under the hole so the guide has something to work with. Make sure to keep the bit cool and don't stop with the saw in the cut.

I would use a guide and drill it larger, like you I haven't used a router in years.

A piece of wood drilled just large enough for the intended hole clamped down.

A piece of wood drilled just large enough for the intended hole clamped down.

Are the drain holes 1 1/2” or do they hole a 1 1/2” bulkhead. I would go with at least 1 1/2” drain pipes, if you have the options, I would do 3 drains, two with valves so you can control noise and one emergency in case one gets plugged. I know in my RedSea S1000, I cannot run my two 3100gph pumps full power, so more drain you can control is better than too little.Is there any min distance from the edge of that hole I should do? Ie 1/8” from the edge of the hole to get a clean new cut? Also drain tubes are 1.5” those should be good or do I need to enlarge those as well?

As far as the holes, if your guide is secure you can go pretty much right on the edge. Your bulkheads have about a 1/4” overlap with a rubber seal so small imperfection won’t affect anything. But you can leave an 1/8” just so your hole saw doesn’t catch on that area. Acrylic should drill fairly easily, just take it slow, and stop to let it cool. If it gets too hot, it kind of melts and can stick the hole saw.

Sorry the drain tubes are 1 1/4” Id so the bulkhead hole is larger. I’ll have to drill them larger. Not sure why I thought they were 1.5”. I currently have 2. The return lines come up through the overflow box come out the top and go left and right to the 6 holes on the top. I have thought about taking the return lines and running them up the back of the tank and not coming through the overflow box so I could make the tank have 4 drain tubes. I’m going to be running a uv off one return line so external to the top of the tank would prob be easier. I’ve added pics of the top and bottom of my tank for referenceAre the drain holes 1 1/2” or do they hole a 1 1/2” bulkhead. I would go with at least 1 1/2” drain pipes, if you have the options, I would do 3 drains, two with valves so you can control noise and one emergency in case one gets plugged. I know in my RedSea S1000, I cannot run my two 3100gph pumps full power, so more drain you can control is better than too little.

As far as the holes, if your guide is secure you can go pretty much right on the edge. Your bulkheads have about a 1/4” overlap with a rubber seal so small imperfection won’t affect anything. But you can leave an 1/8” just so your hole saw doesn’t catch on that area. Acrylic should drill fairly easily, just take it slow, and stop to let it cool. If it gets too hot, it kind of melts and can stick the hole saw.

Probably 2. 1 1/4” overflow would be ok. Tha Red Sea only has one. Then convert the other two to emergency. Bring the returns up the back and you would be good IMO. Not sure what size your returns up top are, but I would probably go with the four 3/4”.

You can also get line loc with a tee and be able to direct the return lines in several directions to really get some random flow.

Right now the returns on top are currently 1/2” I was planning on taking them to 1” or 3/4”. Prob 3/4 for more pressure on the flowProbably 2. 1 1/4” overflow would be ok. Tha Red Sea only has one. Then convert the other two to emergency. Bring the returns up the back and you would be good IMO. Not sure what size your returns up top are, but I would probably go with the four 3/4”.

Last edited:

Either would be ok. But I would reduce down to 3/4 at the tank for the ability to add things like lineloc. I added their t with two random flow generators from bulkreef or somewhere as it disperses better and doesn’t affect the sand bed so much if you are using sand.

So I’m finally ready to drill out the bulkhead holes for my tank. My plans got derailed from my 180 freshwater deciding it was time for seals to fail. This is what I’m thinking for bulkhead placement. The two larger ones are 1-1/4 and the smaller ones are 1”. The black line represents where the opening ends on the stand. I can’t enlarge the stand opening cause the back horizontal brace is right there. This seems to be the only way to get all 4 drain lines in there but wanted some feedback prior to drilling the holes.

Was looking at that last night and was like oh crap! I’m trying to find the best way to get the flow I need but I’m struggling with the small area I have to put bulkheadsHow are you going to spin the bulkhead nut if the sides are against one another

my 300 i cut a big hole (like turned your 4 holes into one. and then extended the acrylic all the way down to the sump so it doesnt have any bulkheads. i have the whole column filled with bio balls works great and silences the water on the way down.. i run a jeboa 20000 at 80% for the return pump and its quiet.

This what I’d do. I would get some Scrap Acrylic, as close to the Thickness of your tank as you can. Drill the Smaller Hole First, then the Larger Hole, to get a feel of how the tools are going to respond. Also the general location of the holes. It can get pretty dicey when the pilot bit isn’t guiding the Hole-saw, even with a guide. When I cut Acrylic on my Table Saw, I spray the Blade with Teflon Dry Lube, and rub Bee’s Wax on the Acrylic Backing Paper. A lot of Independent Glass Shops Work Acrylic, and maybe a source for Scraps. Another Source would be a Card Shop or Book Store, as they throw out displays.

So your acrylic comes down and then angles down towards one side of the sump? I’ve at attached a photo of the sump I had built for reference and I think I would still need bulkheads at the bottom but could be wrong. I have 2 ecotech m2 pumps I’ll be using for returns. I’m running 2 return pumps for a few reasons. One is redundancy and the other is with this being a 8 ft tank I’ll have one pump to 3 discharges on one side and the same on the other. I also will be running a UV sterilizer off one of the pumps.my 300 i cut a big hole (like turned your 4 holes into one. and then extended the acrylic all the way down to the sump so it doesnt have any bulkheads. i have the whole column filled with bio balls works great and silences the water on the way down.. i run a jeboa 20000 at 80% for the return pump and its quiet.

Attachments

Similar threads

- Replies

- 1

- Views

- 127

- Replies

- 2

- Views

- 85

- Replies

- 1

- Views

- 59

- Replies

- 5

- Views

- 335